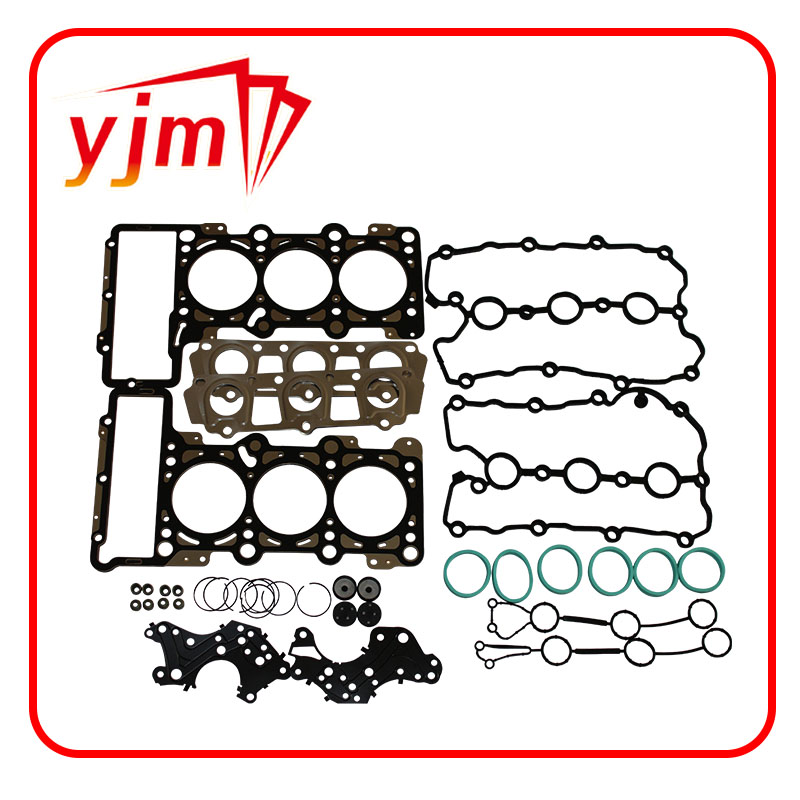

flat o ring gasket

Understanding Flat O-Ring Gaskets Design, Function, and Applications

Flat O-ring gaskets are crucial components widely used in various industries, serving as sealing devices that prevent the leakage of fluids and gases in numerous applications. These simple yet effective gaskets have gained popularity due to their reliability, ease of installation, and versatility.

What is a Flat O-Ring Gasket?

A flat O-ring gasket is typically made from a circular elastomer or rubber material that has been cut or molded into a specific flat shape. Unlike traditional O-rings, which are toroidal (doughnut-shaped) and generally used in cylindrical applications, flat O-rings are designed to be placed between two flat surfaces. The design of the gasket allows it to compress between the two surfaces, forming an effective seal when pressure is applied.

Material Composition

Flat O-ring gaskets are available in a variety of materials, each selected based on the specific requirements of the application. Common materials include

1. Nitrile Rubber (NBR) This is the most common material used for flat O-ring gaskets, offering excellent resistance to petroleum-based oils and fuels, making it suitable for automotive and hydraulic applications.

2. Viton (FKM) Known for its high-temperature resistance and compatibility with a wide range of chemicals, Viton is ideal for applications exposed to extreme heat and aggressive fluids.

3. Silicone This rubber is resilient in high and low temperature applications, making it perfect for food-grade and medical applications, where flexibility and compliance with health regulations are paramount.

4. PTFE (Teflon) When chemical resistance is critical, PTFE gaskets provide excellent isolation against corrosive agents.

The choice of material directly affects the performance and lifespan of the gasket, making it essential to carefully evaluate the environment and substances with which the gasket will come into contact.

Applications

Flat O-ring gaskets are employed in numerous industries, including

flat o ring gasket

- Automotive Used in engine assemblies, fuel tanks, and transmission systems, flat O-ring gaskets prevent leaks that could cause engine failure or environmental hazards

.- Aerospace In aircraft systems, flat O-rings help ensure airtight seals for hydraulic and pneumatic components, contributing to the overall safety and performance of the aircraft.

- Manufacturing In machines and equipment where fluid dynamics are critical, flat O-ring gaskets are employed in pumps, valves, and compressors to prevent leaks and maintain efficiency.

- Plumbing Flat O-rings are commonly used in home and industrial plumbing systems to seal couplings and prevent water leaks.

Advantages of Flat O-Ring Gaskets

The popularity of flat O-ring gaskets can be attributed to several key advantages

1. Ease of Installation Their flat design allows for simple installation without the need for special tools or equipment, enabling quick replacements and maintenance.

2. Cost-Effectiveness Flat O-ring gaskets are relatively inexpensive to produce and offer long-lasting durability, reducing the need for frequent replacements.

3. Customizability Manufacturers can customize the size and material based on specific application requirements, enhancing their versatility.

4. Effective Sealing Capabilities Flat O-rings create tight seals that can withstand significant pressure, which is crucial in preventing leaks in high-stakes environments.

Conclusion

Flat O-ring gaskets are integral components in various industries, offering reliability and efficiency in sealing applications. Understanding the properties of different materials, their applications, and the benefits they provide can help engineers and technicians select the right gasket for their specific needs. As technology continues to evolve, so too will the designs and materials used in flat O-ring gaskets, promising to improve performance and broaden their applicability in the future. Whether in automotive, aerospace, or manufacturing contexts, these simple yet effective seals play a vital role in maintaining the integrity and efficiency of systems worldwide.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories