Flat Gasket Seals for Reliable Leak Proofing in Various Applications

Understanding Flat Gasket Seals Importance and Applications

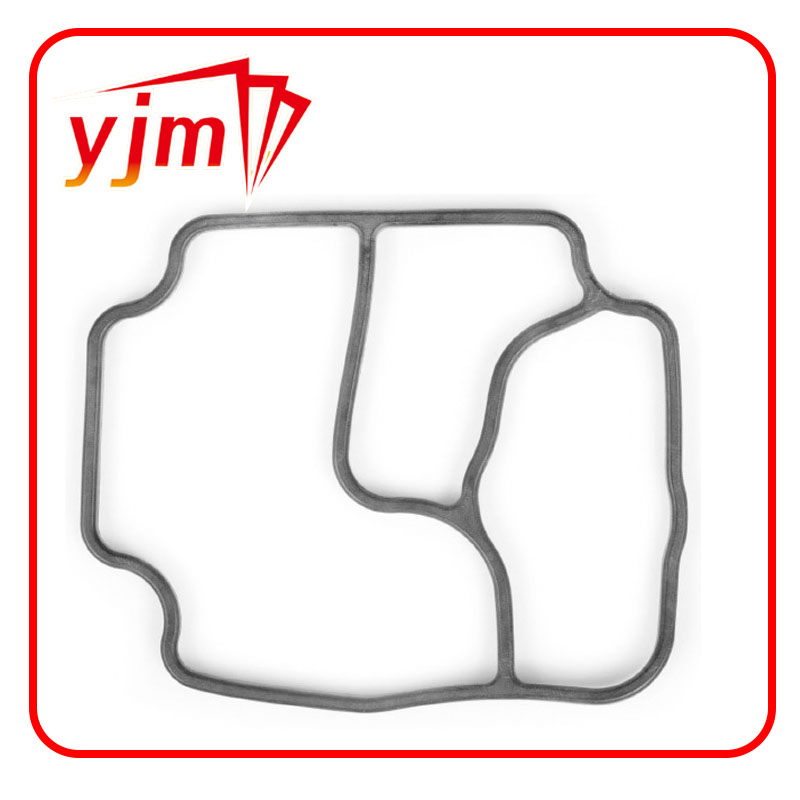

Flat gasket seals are essential components in various industrial and mechanical applications, serving as critical barriers that prevent fluid or gas leakage between mating surfaces. These seals are often made from a variety of materials, including rubber, cork, metal, and composite materials, depending on the specific requirements of the application. Their primary function is to ensure a tight seal under different pressure and temperature conditions, making them vital in a range of industries from automotive to aerospace.

One of the key advantages of flat gasket seals is their versatility. They can be manufactured in different thicknesses and sizes to accommodate various flange configurations. The design of the gasket is tailored to match the surfaces it seals, which allows for effective sealing even in challenging environments. This adaptability makes flat gaskets suitable for use in engines, piping systems, and hydraulic systems, where they help to maintain the integrity of the system by minimizing the risk of leaks.

In automotive applications, flat gasket seals are commonly found in engines, where they serve to seal components such as cylinder heads, oil pans, and intake manifolds. The reliability of these gaskets ensures that the engine operates efficiently, reducing the chances of oil or coolant loss that could lead to severe mechanical failures. In industrial settings, these gaskets are critical in bolted joints, ensuring that pressure vessels and pipelines operate safely under high pressures.

flat gasket seal

When selecting a flat gasket seal, factors such as temperature resistance, chemical compatibility, and pressure rating must be considered. Different materials exhibit different properties, which can significantly impact the performance of the gasket. For example, silicone gaskets can withstand high temperatures but may not be suitable for aggressive chemicals, while PTFE gaskets are highly resistant to a wide range of chemicals but may not have the same temperature endurance.

Installation is another important aspect of flat gasket seals. Proper installation techniques ensure that the gasket performs as intended. It is crucial to clean the mating surfaces thoroughly and apply the correct amount of torque to the bolts securing the joint. Over-torquing can lead to gasket failure, while under-torquing can result in leaks.

In conclusion, flat gasket seals are indispensable in ensuring the efficiency and safety of various machinery and equipment. Their ability to adapt to different environments and their ease of installation make them a preferred choice across multiple sectors. As technology advances, the development of new materials and manufacturing techniques will continue to enhance the performance and reliability of flat gaskets, ensuring their place in modern engineering.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories