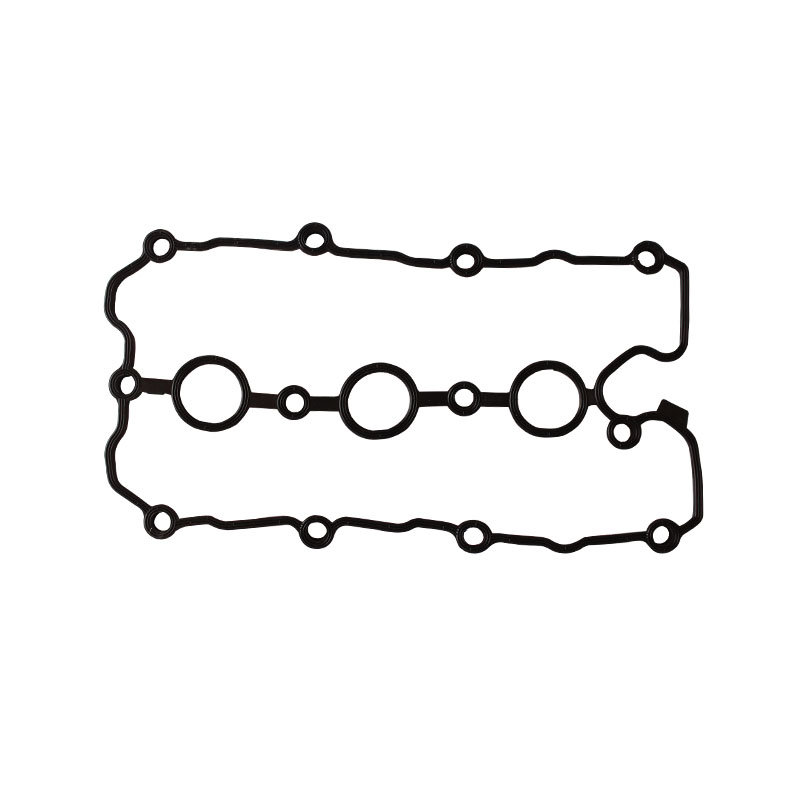

flat face o rings

The Importance of Flat Face O-Rings in Various Industries

O-rings are ubiquitous in various engineering applications, serving as vital components for ensuring a tight seal in systems that require fluid retention or containment. Among the various types of O-rings available, flat face O-rings have gained significant attention due to their unique design and functionality. This article delves into the characteristics, applications, and advantages of flat face O-rings, emphasizing their role in ensuring operational efficiency and safety across multiple industries.

Understanding Flat Face O-Rings

Flat face O-rings, unlike traditional round O-rings, feature a distinctive flat profile. This design enables these O-rings to be used in applications where space constraints and sealing requirements demand an alternative to conventional circular shapes. The flat surface allows for more contact area with the sealing surfaces, which can improve the sealing performance in certain circumstances.

Flat face O-rings are typically manufactured from elastomeric materials, including rubber compounds such as nitrile, EPDM, and silicone. These materials offer excellent resistance to temperature fluctuations, chemical exposure, and wear, making flat face O-rings suitable for a diverse range of environments.

Applications of Flat Face O-Rings

Flat face O-rings are utilized in various industries, including

1. Hydraulics and Pneumatics In hydraulic and pneumatic systems, maintaining pressure is crucial. Flat face O-rings provide reliable seals that can withstand high pressures and prevent leakage in cylinders, valves, and connectors.

2. Automotive Industry The automotive sector employs flat face O-rings in applications such as fuel systems, engine components, and braking systems. Their ability to resist oil, fuels, and extreme temperatures contributes to vehicle performance and safety.

3. Aerospace In aerospace applications, flat face O-rings are essential for sealing fuel tanks, hydraulic systems, and critical components on aircraft. The rigorous standards and reliability requirements in this industry necessitate seals that can handle temperature extremes and high pressures.

flat face o rings

4. Food and Beverage In the food and beverage industry, cleanliness and safety are paramount. Flat face O-rings made from food-grade materials offer a solution to seal machinery and prevent contamination, ensuring compliance with health regulations.

5. Chemical Processing Chemical plants often require seals that can withstand aggressive solvents and reactive substances. Flat face O-rings are available in materials that resist degradation from harsh chemicals, ensuring a secure seal.

Advantages of Flat Face O-Rings

The unique profile of flat face O-rings offers several advantages

1. Increased Surface Contact The flat design allows for more surface area contact with the mating surfaces, potentially improving the sealing capabilities and reducing the chances of leakage.

2. Space Efficiency In applications where there are spatial constraints, flat face O-rings can be installed in places where traditional round O-rings may not fit properly, allowing for more versatile design options.

3. Customization Manufacturers can tailor flat face O-rings to specific sizes and materials, catering them to the precise requirements of an application.

4. Durability Given their robust material options, flat face O-rings can be engineered to withstand extreme environments, offering longevity and reducing maintenance costs.

Conclusion

Flat face O-rings play a crucial role in diverse industries, providing effective sealing solutions that enhance performance and safety. Their unique design, combined with the flexibility of materials and customization options, makes them indispensable in numerous applications. As technology advances and the demand for reliable sealing solutions grows, flat face O-rings will undoubtedly continue to be a vital component in various engineering and manufacturing processes. Understanding and leveraging the benefits of flat face O-rings can lead to improved operational efficiency and reliability across multiple sectors.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories