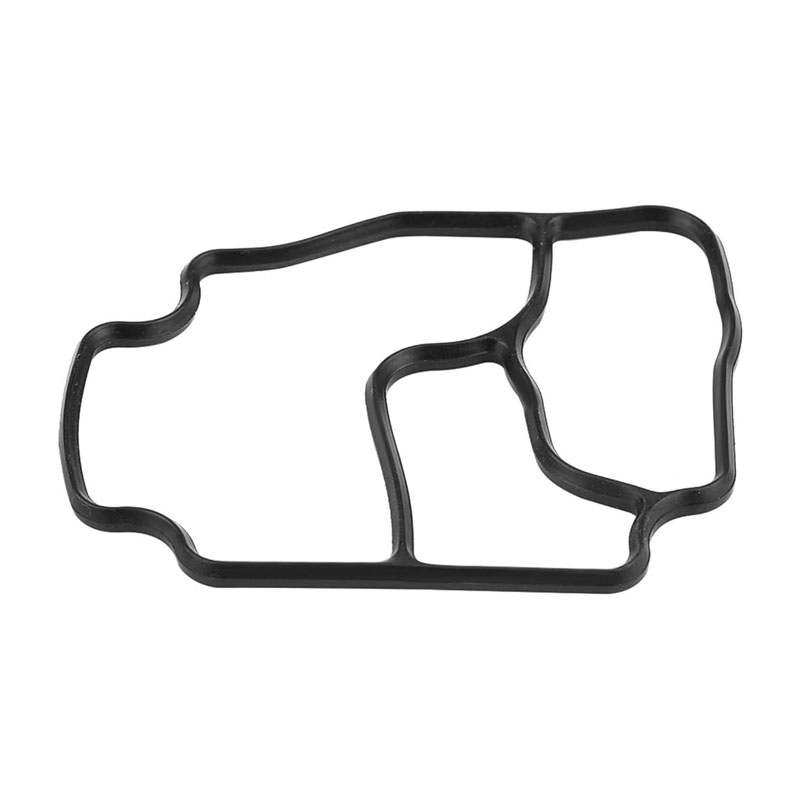

High-Performance Flat Gasket Seals for Reliable Sealing Solutions

Flat Gasket Seals Essential Components in Fluid Management

Flat gasket seals are crucial components in various industrial applications, serving as effective barriers that prevent leakage between two surfaces. These seals are designed to create a tight seal under compression, enhancing the integrity of mechanical systems. Typically made from materials such as rubber, cork, paper, or composite materials, flat gaskets offer excellent resistance to chemicals, heat, and pressure, making them suitable for a wide range of environments.

One of the primary functions of a flat gasket seal is to prevent the escape of fluids in piping systems and machinery

. In industries such as automotive, manufacturing, and oil and gas, these seals play a key role in maintaining operational efficiency and safety. A failure in sealing can lead to significant fluid loss, which not only affects productivity but can also pose safety hazards and environmental risks.The manufacturing process of flat gaskets involves cutting the material into precise shapes that fit the flanges or surfaces of the components they join. The design and thickness of the gasket can significantly impact its ability to seal effectively. For instance, thicker gaskets may provide better sealing capabilities but may not be ideal for applications with limited space. Conversely, thinner gaskets can fit into tighter spaces but may require more careful handling to prevent deformation.

flat gasket seal

In addition to their sealing capabilities, flat gaskets also absorb vibrations and thermal expansion, which can be critical in preventing damage to connected parts. This is particularly important in applications subject to fluctuating temperatures or constant movement, as it helps maintain structural integrity over time.

Selecting the right flat gasket seal involves considering factors such as operating temperature, pressure, and the types of fluids involved. For example, in high-pressure environments, selecting a gasket with higher tensile strength and elasticity is essential to prevent blowouts. Furthermore, compatibility with various chemicals is vital to ensure longevity and reliability.

In conclusion, flat gasket seals are indispensable in ensuring the efficient and safe operation of machinery and piping systems across various industries. Their ability to provide reliable sealing under diverse conditions highlights their significance in fluid management systems, emphasizing the need for careful selection and maintenance to avoid potential failures. As technology progresses, the development of new materials and designs will continue to enhance the performance of flat gasket seals, further solidifying their role in industrial applications.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories