fkm oil seal

Understanding FKM Oil Seals A Comprehensive Overview

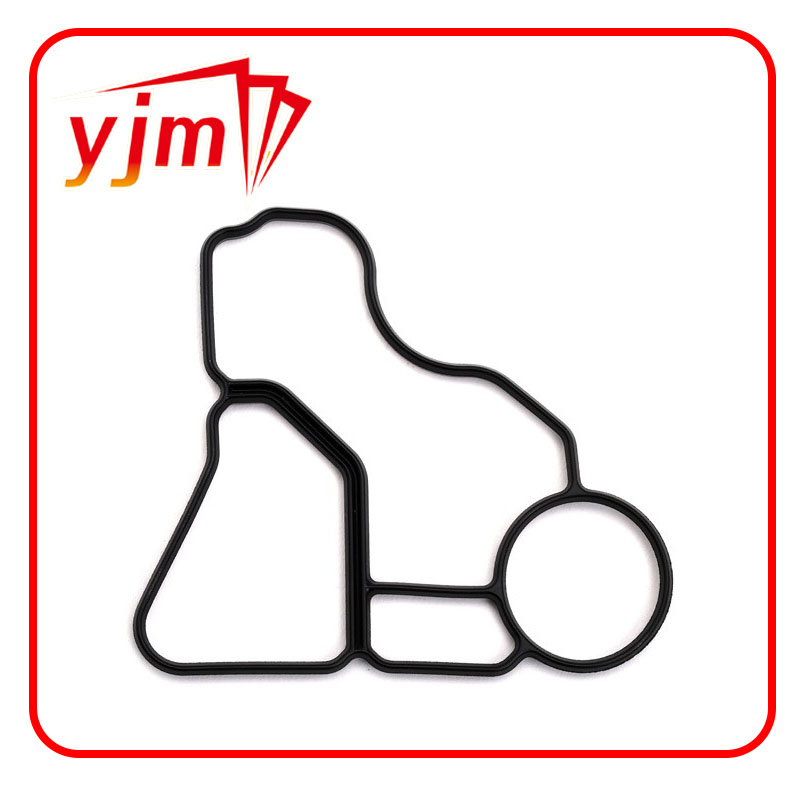

FKM oil seals, also known as fluorocarbon oil seals, are critical components widely used in various engineering applications. These seals are designed to prevent the leakage of lubricants and other fluids, ensuring the optimal performance of machinery and equipment. Made from a synthetic rubber known for its excellent resistance to heat, chemicals, and aging, FKM oil seals offer a reliable solution for sealing applications in harsh environments.

Understanding FKM Oil Seals A Comprehensive Overview

Another significant benefit of FKM oil seals is their high-temperature resistance. These seals can operate effectively in temperatures ranging from -20°C to 200°C (-4°F to 392°F), making them suitable for high-performance engines and equipment that generate substantial heat during operation. The ability to maintain performance under extreme temperatures is crucial for the longevity of machinery and reduces the likelihood of failure, thereby decreasing maintenance costs over time.

fkm oil seal

The design and composition of FKM oil seals also contribute to their effectiveness. They are available in various shapes, sizes, and configurations, which allows them to fit different applications seamlessly. Whether it’s a simple round oil seal or a custom-designed solution, manufacturers can tailor FKM seals to meet specific operational requirements. This versatility extends to their installation, as they can be easily fitted into existing systems, ensuring a tight and reliable seal.

However, it is essential to note that while FKM oil seals are incredibly resilient, they are not suitable for all applications. Their performance can be affected by certain environments, particularly those involving low-molecular-weight fluids or steam. Therefore, it is crucial for engineers and technicians to understand the specific requirements of their applications when selecting oil seals.

In conclusion, FKM oil seals play an indispensable role in maintaining the integrity of various systems across multiple industries. Their superior chemical resistance, high-temperature capability, and versatile design make them a preferred choice for manufacturers and engineers alike. As technology continues to advance, the formulations and applications of FKM seals are likely to expand, further enhancing their effectiveness and reliability in sealing solutions. For anyone involved in engineering or machinery maintenance, understanding the value and applicability of FKM oil seals can significantly impact operational efficiency and equipment longevity.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories