fenner oil seal

Understanding Fenner Oil Seals A Comprehensive Guide

Fenner oil seals are a crucial component in various mechanical systems, providing effective sealing solutions to prevent the leakage of lubricants and other fluids. These seals are essential in many applications, from automotive engines to industrial machinery, ensuring optimal performance and longevity. This article will delve into the importance, design, types, applications, and maintenance of Fenner oil seals.

The Importance of Oil Seals

Oil seals, also known as grease seals, play a significant role in maintaining the efficiency and reliability of mechanical equipment. By preventing oil leaks, they help in reducing friction between moving parts, which is vital in minimizing wear and tear. This ultimately leads to higher operational efficiency and extends the lifespan of machinery. When oil seals fail, it can result in severe damage to components, increased maintenance costs, and even complete failure of the machinery. Therefore, selecting the right oil seal is critical for any mechanical assembly.

Design and Composition

Fenner oil seals are engineered using advanced materials and techniques to withstand various operating conditions. Typically composed of elastomers, such as nitrile or silicone, these seals exhibit excellent resistance to temperature fluctuations, abrasion, and chemical exposure. The design of a Fenner oil seal often features specific geometry such as lip designs, which enhance sealing capabilities by ensuring optimal contact with the surfaces it interfaces with.

These seals generally consist of three critical components the seal body, the sealing lip, and a metal or elastomeric reinforcer. The reinforcer provides structural integrity, allowing the seal to maintain its shape under pressure. The precision in the seal’s design ensures minimal friction and extended service life, making Fenner oil seals a reliable choice in demanding environments.

Types of Fenner Oil Seals

Fenner offers a variety of oil seals tailored for different applications, including

1. Single-Lip Seals The most common type, ideal for light-duty applications where the risk of contamination is low. 2. Double-Lip Seals An effective solution for more challenging environments where additional sealing protection is needed against dirt and moisture.

3. Spring-Loaded Seals These seals include a spring around the sealing lip, which helps maintain constant pressure against the shaft, adapting to wear over time.

fenner oil seal

4. Specialty Seals Fenner also manufactures seals for specific industries, including food and beverage processing, pharmaceuticals, and chemical handling, where stringent hygiene standards must be met.

Applications

Fenner oil seals find use across various sectors, including

- Automotive Industry In vehicles, oil seals are utilized in engines, transmissions, and differentials to prevent oil leakage and maintain optimal performance. - Industrial Machinery Manufacturing equipment like pumps, gearboxes, and compressors rely on oil seals for smooth operation and to keep contaminants out.

- Aerospace and Marine These seals are also critical in specialized applications where safety and reliability are paramount, such as in engines and other moving parts subject to high loads and environmental factors.

- Agriculture Equipment such as tractors and harvesters uses Fenner oil seals to ensure efficient operation in harsh conditions.

Maintenance and Installation

Proper maintenance and installation of Fenner oil seals are crucial to their performance. When installing, it is essential to ensure that the sealing lip is correctly oriented and that the shaft surface is smooth to avoid premature wear. Regular inspection of seals for signs of wear or damage can help in early detection of potential leaks, saving time and money in repairs.

Moreover, best practices in lubrication should be followed as per manufacturer guidelines. Over-lubrication can cause seal failure just as significantly as under-lubrication can, so balance is key.

Conclusion

In summary, Fenner oil seals are integral to the performance and reliability of various mechanical systems. Their design, composition, and the range of applications they serve highlight their importance in industrial and automotive contexts. Choosing the right Fenner oil seal, coupled with appropriate maintenance practices, can significantly enhance the operational efficiency and lifespan of machinery, making them a valuable investment for any industry relying on mechanical components.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

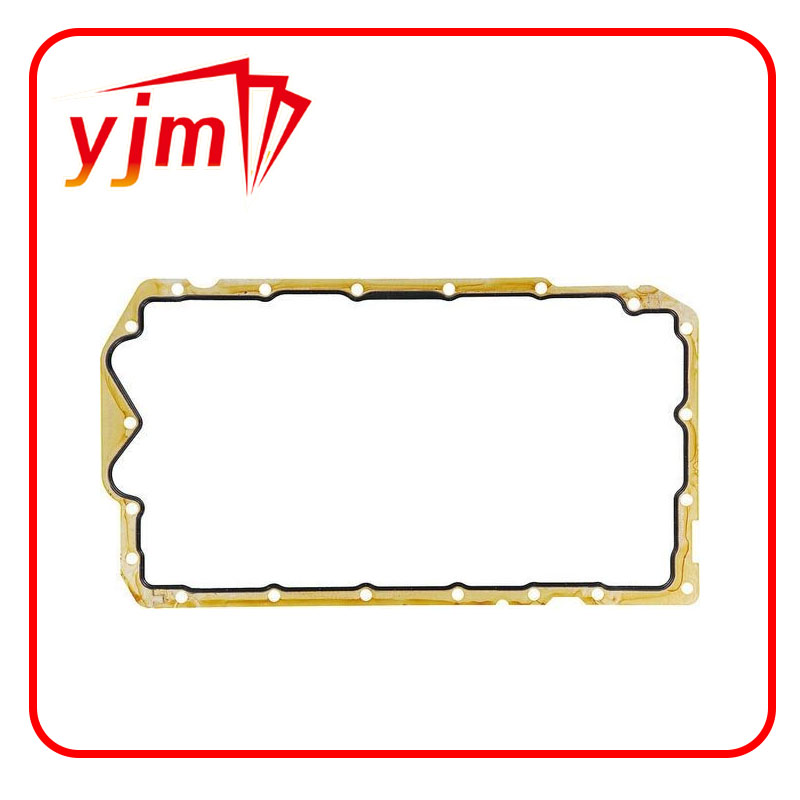

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories