Exploring the Features and Benefits of CFW Oil Seals for Enhanced Machinery Performance

Understanding CFW Oil Seals Importance, Applications, and Benefits

Oil seals, commonly referred to as lip seals, play a crucial role in various mechanical systems by preventing the leakage of lubricants and the ingress of contaminants. Among the many types available, CFW oil seals have gained prominence in the industry due to their reliability and performance. This article explores the significance of CFW oil seals, their applications, and the benefits they bring to various sectors.

The Importance of Oil Seals

Oil seals are designed to ensure that lubricants remain within a system while keeping harmful substances from entering. This dual-function is critical for maintaining the efficiency and longevity of machinery. Without effective seals, lubrication can be compromised, leading to increased wear and tear, overheating, and ultimately, mechanical failure. CFW oil seals are engineered to withstand challenging conditions, providing a robust solution for numerous applications.

Applications of CFW Oil Seals

CFW oil seals are utilized in various sectors, including automotive, industrial, and construction machinery. In the automotive industry, these seals are commonly found in transmissions, differential gearboxes, and engines. They are essential for maintaining optimal lubrication in critical components, such as bearings and shafts.

In industrial settings, CFW oil seals are used in pumps, motors, and gearboxes, ensuring that machinery operates smoothly without loss of lubricant. Their capability to handle high pressures and temperatures makes them suitable for even the most demanding environments. In construction machinery, these seals protect hydraulic systems and prevent fluid leakage, contributing to the effective operation of excavators, bulldozers, and other heavy equipment.

The Benefits of Using CFW Oil Seals

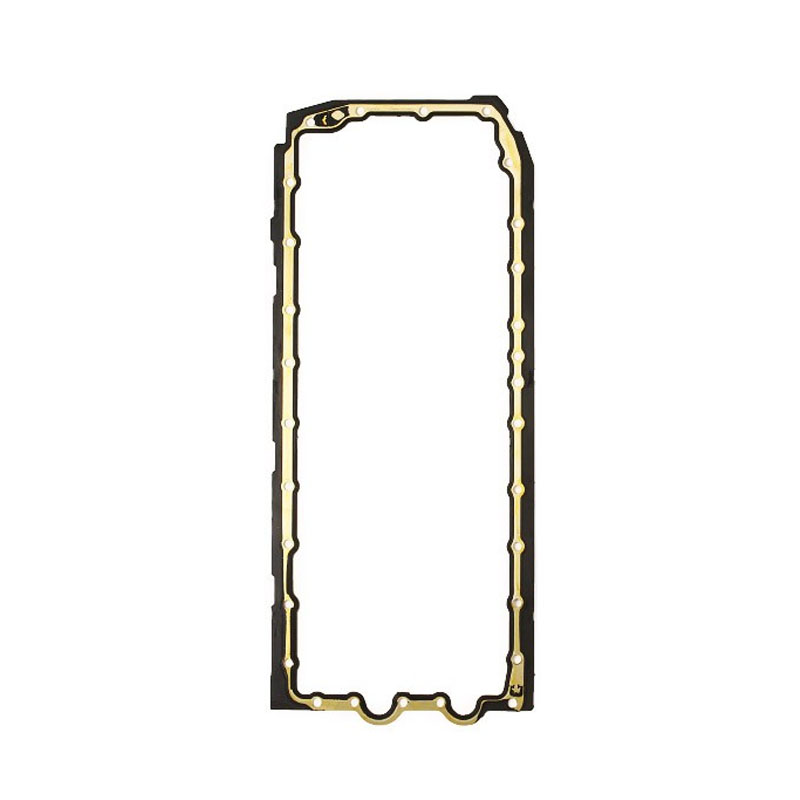

cfw oil seal

1. Enhanced Durability CFW oil seals are made from high-quality materials that provide superior resistance to wear, heat, and chemical exposure. This durability translates to longer service life and reduced maintenance needs, ultimately saving costs for operators.

2. Leak Prevention One of the most significant advantages of CFW oil seals is their effectiveness in preventing leaks. By creating a tight seal, these products protect the integrity of lubricants, ensuring that machinery operates efficiently without the risk of contamination.

3. Reduced Friction Properly functioning CFW oil seals reduce friction between moving parts. This reduction not only improves efficiency but also minimizes energy consumption, making equipment more sustainable in the long run.

4. Versatility CFW oil seals are available in various sizes and configurations, making them versatile enough to fit a wide range of applications. This adaptability ensures that users can find the right seal for their specific needs, enhancing operational flexibility.

5. Easy Installation Most CFW oil seals are designed for straightforward installation, reducing downtime during maintenance or repair. Users can quickly replace worn or damaged seals, ensuring that machinery can get back to work with minimal disruption.

Conclusion

In conclusion, CFW oil seals play an essential role in the performance and reliability of various mechanical systems. Their ability to prevent leaks, enhance durability, and reduce friction makes them a valuable component in automotive, industrial, and construction applications. As businesses strive for efficiency and sustainability, adopting high-quality oil seals like CFW not only protects investments in machinery but also fosters a more effective operational environment. By understanding the importance and benefits of CFW oil seals, companies can make informed decisions that contribute to the reliability and longevity of their equipment.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories