Exploring the Benefits of Brake Fluid Resistant O-Rings for Enhanced Sealing and Durability Performance

Understanding Brake Fluid Resistant O-Rings

O-rings are vital components in various mechanical systems where seals are required to prevent leaks. Among the many applications of O-rings, their resistance to specific fluids is essential, especially in the automotive industry, where they are used in brake systems. One of the most critical attributes of O-rings is their compatibility with brake fluid, which can be corrosive and can cause material degradation. This article discusses the importance of brake fluid resistant O-rings, their materials, and their applications.

The Importance of Brake Fluid Resistant O-Rings

In automotive brake systems, O-rings serve as seals to prevent the escape of brake fluid, ensuring that the system maintains the necessary pressure for effective braking. Brake fluid is a hydraulic liquid that transmits force through the braking system; however, it can be particularly aggressive. Therefore, using O-rings that can withstand brake fluid exposure is crucial. If the O-rings degrade, this can lead to leaks, reduced braking performance, and potential safety hazards.

Materials for Brake Fluid Resistant O-Rings

The type of material used in manufacturing brake fluid resistant O-rings is essential for their performance and longevity. Common materials include

1. Nitrile Rubber (NBR) This is one of the most widely used materials for O-rings in brake systems. NBR exhibits excellent resistance to petroleum-based fluids, including brake fluid. It provides good sealing capabilities and durability, making it an appropriate choice for automotive applications.

2. Fluoroelastomers (FKM) Known for their superior heat and chemical resistance, fluoroelastomers, such as Viton, can withstand a wide range of temperatures and are highly resistant to brake fluid. These materials are more expensive but offer enhanced performance in demanding conditions.

3. Polyacrylate This type of elastomer provides good resistance to high temperatures and is also suitable for brake fluid applications. Polyacrylate O-rings can be a good alternative when working under extreme conditions.

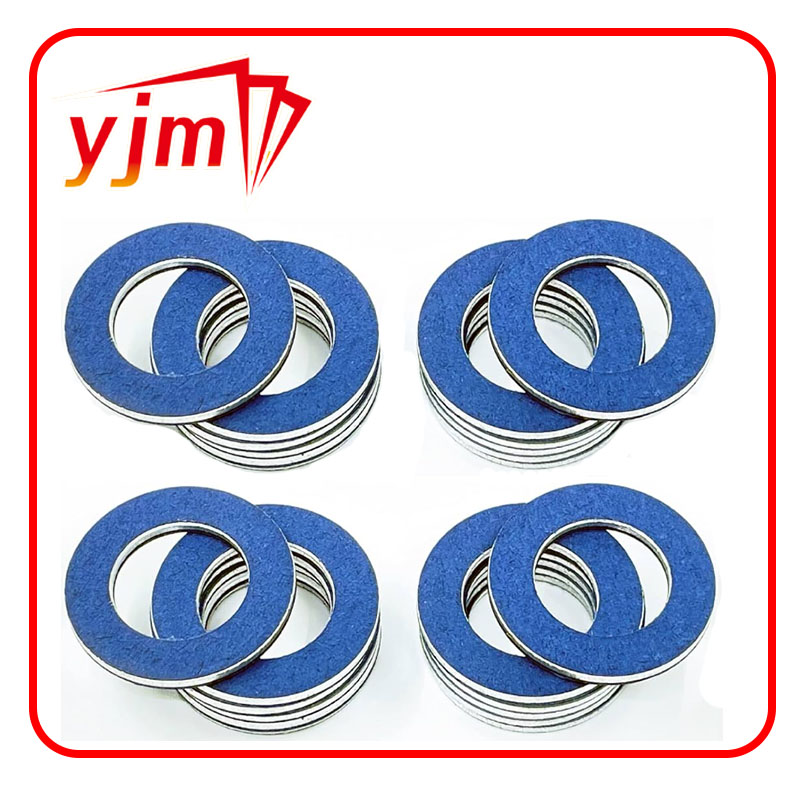

brake fluid resistant o rings

4. Silicone Rubber While silicone O-rings have excellent temperature resistance, their compatibility with brake fluid can vary, making them less commonly used in this application unless specifically formulated for superior performance.

Benefits of Using Properly Selected O-Rings

Utilizing brake fluid resistant O-rings in brake systems not only helps in maintaining system integrity but also enhances overall vehicle performance. Here are some key benefits

- Safety The primary function of brake O-rings is to ensure that brake fluid does not leak. A failure in sealing can lead to brake failure, posing significant safety risks. Reliable O-rings minimize these risks.

- Longevity High-quality O-rings that are resistant to brake fluids can lead to reduced maintenance and lower replacement costs, as they are less likely to degrade over time.

- Performance Effective sealing provided by proper O-rings ensures that braking systems operate smoothly, providing drivers with confidence and control.

Conclusion

In conclusion, brake fluid resistant O-rings are crucial components in ensuring the safe operation of hydraulic braking systems. Selecting the appropriate material based on the specific requirements of the application is essential to prevent failures and maintain high performance. With advancements in material science, manufacturers can produce O-rings that withstand the aggressive nature of brake fluids while ensuring durability and longevity. Proper maintenance and regular inspections of O-rings can significantly contribute to overall vehicle safety and performance, making them an indispensable part of automotive design.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories