Exploring the Benefits and Applications of Hub Seal Oil in Industrial Machinery

Understanding Hub Seal Oil Importance, Uses, and Benefits

Hub seal oil, a critical component in various mechanical systems, plays an essential role in ensuring the smooth operation and longevity of machinery. Used primarily in automotive and industrial applications, this specialized oil is formulated to lubricate bearings and seal components, preventing wear and tear, ensuring efficient operation, and mitigating equipment failures.

What is Hub Seal Oil?

Hub seal oil is a lubricating oil designed specifically for use in hub assemblies. These hubs are found in numerous applications, from automotive wheel bearings to industrial machinery. The oil provides a sealing function, preventing contaminants like dirt and water from entering the bearing spaces while simultaneously lubricating internal components. This dual function is vital in maintaining the integrity and performance of the machinery.

Importance of Hub Seal Oil

The significance of hub seal oil can be attributed to several key factors

1. Preventing Wear and Tear In mechanical systems, friction is a primary cause of wear. Hub seal oil reduces friction between moving parts, thus prolonging the lifespan of bearings and other components.

2. Contaminant Prevention Seal oil acts as a barrier that keeps harmful contaminants at bay. Dust, water, and other debris can severely impact the performance and lifespan of machinery, leading to costly repairs and downtime. Hub seal oil’s sealing properties help to maintain a clean environment for the components.

3. Temperature Regulation Continuous operation of machinery generates heat, which, if not managed, can lead to overheating and component failure. Hub seal oil helps dissipate heat, maintaining optimal operating temperatures for bearings and improving overall system efficiency.

4. Operational Efficiency Well-lubricated components operate more smoothly, resulting in less energy consumption and better performance. Hub seal oil contributes to the effective functioning of machinery, which can enhance productivity in industrial settings.

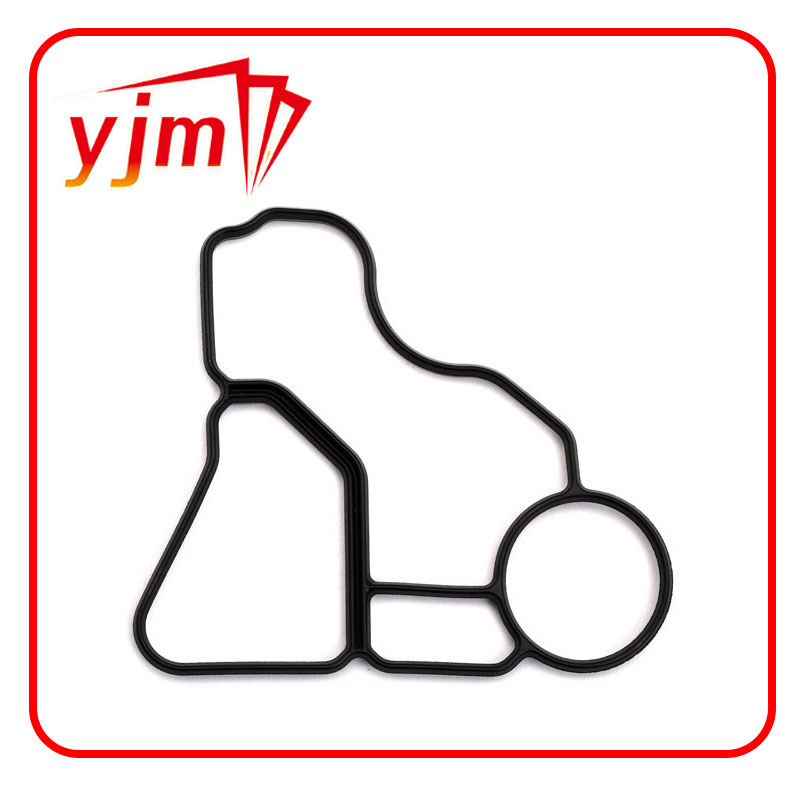

hub seal oil

Applications of Hub Seal Oil

Hub seal oil is widely utilized in various sectors. In the automotive industry, it is integral to vehicles' wheel hubs and axles, ensuring safe and efficient vehicle operation. In industrial machinery, seal oil is essential for heavy equipment, conveyor systems, and manufacturing machinery, where reliability and performance are paramount.

Furthermore, hub seal oil can be found in marine applications, ensuring that equipment exposed to harsh environments—like saltwater—is adequately protected. The versatility of this lubricant highlights its importance across different fields.

Choosing the Right Hub Seal Oil

When selecting hub seal oil, several factors should be considered

- Viscosity The oil's viscosity affects its ability to lubricate and separate components. Different applications may require specific viscosity grades. - Additive Formulation Additives can enhance performance by improving anti-wear properties, oxidation stability, and temperature tolerance. It's crucial to choose a formulation that meets the requirements of the specific application.

- Compatibility Ensure that the hub seal oil is compatible with the materials used in the hub assembly to prevent adverse reactions or degradation over time.

Conclusion

In conclusion, hub seal oil is a vital lubricant in many mechanical systems, preventing wear, protecting against contaminants, and promoting efficient operation. Understanding its importance and applications can help industries select the right products for their specific needs, ultimately leading to better performance and extended lifespans of their equipment. As technology continues to evolve, the significance of specialized lubricants like hub seal oil will likely grow, underscoring the need for ongoing research and development in this essential field.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories