Exploring the Benefits and Applications of Flat Face O-Rings in Various Industries

Understanding Flat Face O-Rings A Comprehensive Guide

O-rings are among the simplest yet most effective sealing solutions in various industrial applications. Among the different types of O-rings available, flat face O-rings have gained popularity for specific uses due to their unique design and functionality. In this article, we will delve into what flat face O-rings are, their advantages, applications, and considerations to keep in mind when using them.

What Are Flat Face O-Rings?

Flat face O-rings, often referred to as flat O-rings, are a type of sealing ring characterized by their flat, circular shape. Unlike traditional O-rings, which have a round cross-section, flat face O-rings have a uniform width and thickness. This design maximizes the sealing surface area, allowing for a more effective seal, which is particularly important when dealing with varying pressures and fluid types.

Advantages of Flat Face O-Rings

1. Enhanced Sealing Performance One of the primary advantages of flat face O-rings is their ability to create a more reliable seal. The flat design provides increased contact with the sealing surfaces, which helps prevent leaks even in high-pressure environments.

2. Versatility Flat face O-rings can be made from various materials, including rubber, silicone, and thermoplastics. This versatility enables them to be used in a wide range of applications, from automotive and aerospace to food processing and pharmaceuticals.

3. Easy Installation The flat design makes these O-rings easier to handle and install compared to traditional O-rings. Their uniform profile allows for more straightforward alignment during installation, reducing the likelihood of damage during the assembly process.

4. Cost-Effectiveness Flat face O-rings are generally less expensive to manufacture and replace compared to other complex sealing solutions. This cost-effectiveness makes them an economical choice for many businesses looking to optimize their sealing applications.

Applications of Flat Face O-Rings

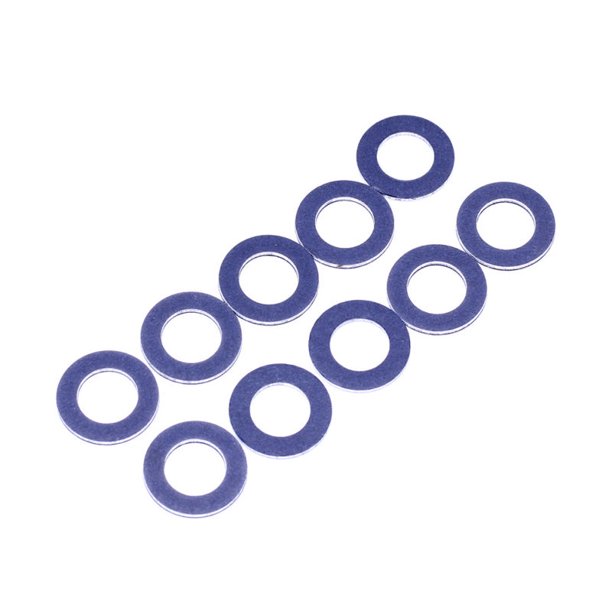

flat face o rings

Flat face O-rings are used extensively across various industries. Some common applications include

- Hydraulic Systems In hydraulic machinery, flat face O-rings provide a robust seal to prevent fluid leakage under high pressure. - Pneumatic Systems These O-rings are also utilized in pneumatic systems, where air pressure variations can lead to seal failure. - Food and Beverage Industry Due to their ease of cleaning and compliance with safety regulations, flat face O-rings are widely used in food processing equipment. - Automotive Sealing In the automotive sector, flat face O-rings are employed in engine components and fuel systems to maintain pressure and prevent leakage.

Considerations When Using Flat Face O-Rings

While flat face O-rings offer numerous benefits, there are several important factors to consider when using them.

1. Material Selection The choice of material for the O-ring is critical. It must be compatible with the fluids and gases it will encounter, as well as able to withstand the operational temperatures.

2. Size Specifications Ensuring the correct size is crucial. An O-ring that is too small or too large may not seal properly, leading to potential leaks.

3. Surface Finish The mating surfaces should be smooth and free from contaminants. Imperfect surfaces can compromise the seal's integrity, resulting in failure.

4. Pressure Ratings Users must understand the pressure and temperature ratings of the O-rings to ensure they will perform well in specific applications.

Conclusion

Flat face O-rings represent an innovative solution for sealing applications across various industries. Their unique design provides enhanced sealing performance, flexibility, and cost-effectiveness, making them an excellent choice for numerous applications. By understanding their advantages and considerations, engineers and technicians can make informed decisions to optimize their sealing processes, ultimately leading to improved efficiency and reliability in their operations.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories