Exploring the Benefits and Applications of Dripless Shaft Seals for Enhanced Equipment Efficiency

Understanding Dripless Shaft Seals Key Features and Benefits

Shaft seals play a crucial role in machinery, preventing leakage of fluids while minimizing contaminants entering the operating components. Among the various types of seals, dripless shaft seals are gaining prominence due to their efficiency and superior performance. This article delves into the features, applications, and benefits of dripless shaft seals.

What is a Dripless Shaft Seal?

Dripless shaft seals, also known as leak-proof or zero-leak seals, are engineered to create a tight seal around rotating shafts. They are designed to contain liquids and prevent leakage, particularly in systems where even a small amount of fluid loss can lead to serious operational issues. These seals are commonly used in various applications, including pumps, motors, and conveyors.

Key Features

1. Innovative Design Dripless shaft seals often incorporate advanced sealing technologies such as lip seals, mechanical seals, or cartridge seals. These designs enhance the ability to maintain a complete seal around the shaft while allowing for smooth rotation.

2. Material Selection High-quality materials such as elastomers, PTFE (polytetrafluoroethylene), and specialized plastics are commonly used in dripless shaft seals. These materials offer excellent resistance to wear, chemicals, and temperature fluctuations, thereby increasing the seal's longevity and reliability.

3. Mechanical Efficiency The design of the dripless shaft seal minimizes friction between the sealing surfaces, which enhances the overall efficiency of the machinery. This efficiency is particularly important in high-speed and high-pressure applications.

4. Versatile Applications Dripless shaft seals are suitable for a wide range of applications across various industries, including automotive, industrial machinery, and marine environments. They can effectively seal against liquids, such as oil, water, and other lubricants.

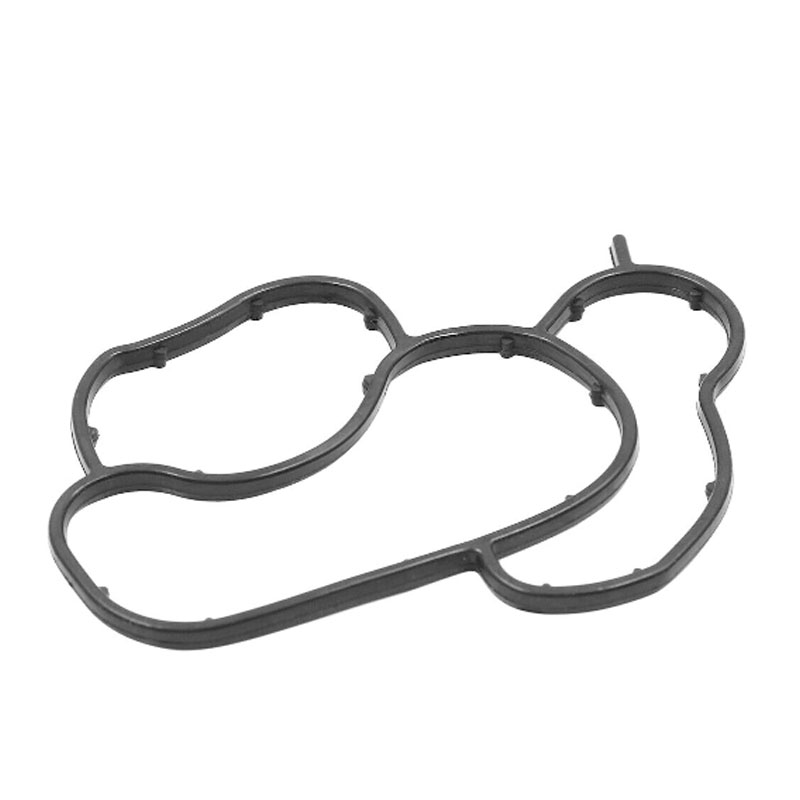

dripless shaft seal

Benefits of Dripless Shaft Seals

1. Leak Prevention One of the primary advantages of dripless shaft seals is their effectiveness in preventing leaks. This not only reduces the risk of environmental contamination but also minimizes the chances of equipment failure due to fluid loss.

2. Maintenance Reduction By preventing leaks, dripless shaft seals contribute to reduced maintenance needs. This means less downtime and lower operational costs, making them an ideal choice for industries that prioritize efficiency and reliability.

3. Cross-Contamination Mitigation Dripless seals protect the machinery by preventing harmful substances from entering the system. This is especially critical in food processing and pharmaceutical industries, where purity and cleanliness are paramount.

4. Extended Equipment Life With reduced leakage and contamination, equipment longevity increases significantly. Dripless shaft seals help in mitigating wear and tear, leading to reduced replacement costs for both seals and the machinery itself.

5. Environmental Compliance As industries face increasing regulatory pressure to reduce environmental impacts, the use of dripless shaft seals can help companies comply with these regulations by minimizing leaks and emissions.

Conclusion

Dripless shaft seals represent an evolution in sealing technology, addressing the critical needs of modern machinery by providing a reliable and efficient sealing solution. Their design innovation, material resilience, and operational benefits make them a preferred choice in various industries. As companies continue to seek ways to improve efficiency and reduce environmental impact, dripless shaft seals will undoubtedly play a pivotal role in achieving these objectives. By integrating such advanced sealing technologies, businesses can enhance their operational reliability and contribute to a more sustainable future.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories