Exploring the Benefits and Applications of Bonded Seal Rings in Various Industries and Technologies

The Importance of Bonded Seal Rings in Industrial Applications

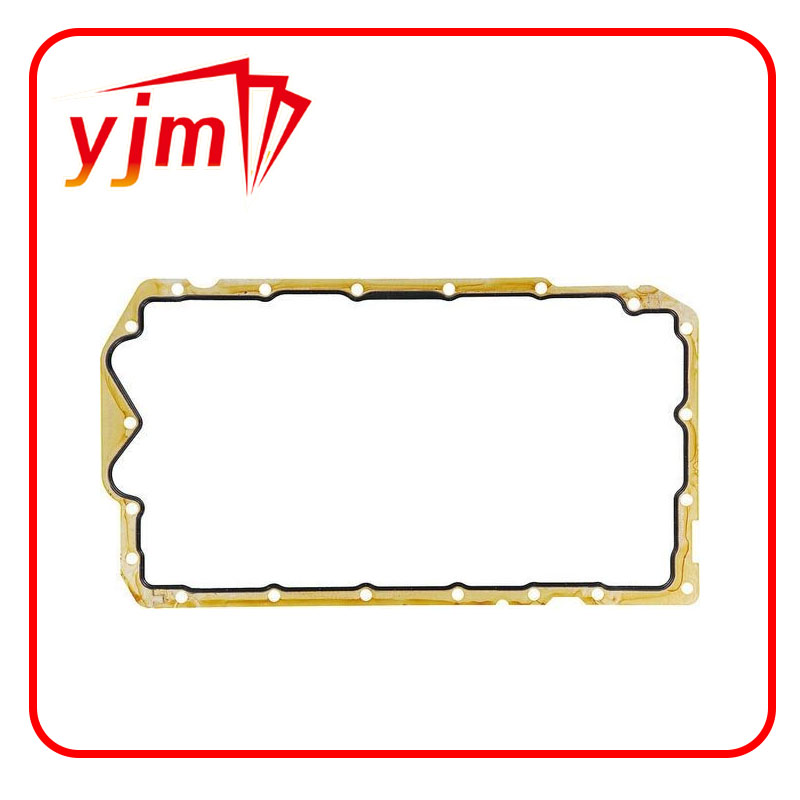

Bonded seal rings are critical components in various industrial applications, specifically designed to provide reliable seals in hydraulic and pneumatic systems. These seals combine a metal washer with a rubber or elastomeric element, enabling them to effectively prevent fluid leaks and maintain pressure in critical systems. This article explores the design, benefits, and applications of bonded seal rings, highlighting their importance in ensuring the efficiency and longevity of machinery and equipment.

Design and Composition

A bonded seal ring typically consists of a circular metal washer that is bonded to an elastomeric material, such as rubber. The metal provides strength and dimensional stability, while the elastomeric element offers flexibility and excellent sealing capabilities. This unique design allows bonded seal rings to withstand temperature fluctuations, pressure changes, and exposure to various chemicals, making them suitable for diverse environments. The rubber is usually made from materials like nitrile, silicone, or fluorocarbon, depending on the specific requirements of the application.

Benefits of Bonded Seal Rings

One of the standout advantages of bonded seal rings is their ability to create a reliable seal under high pressure. The combination of metal and elastomer allows these seals to compress adequately, compensating for any irregularities on the mating surfaces. This ensures that the seal remains intact, preventing leaks that could cause operational failures.

bonded seal ring

Additionally, bonded seal rings offer excellent resistance to wear and tear, extending the lifespan of the components they protect. They can effectively handle vibrations and movement within machinery, which is critical in dynamic applications such as automotive engines and aerospace systems. The versatility of bonded seal rings in accommodating various sizes and designs also makes them an attractive choice for manufacturers looking to standardize parts for different systems.

Applications Across Industries

Bonded seal rings find extensive use in numerous industries, including automotive, aerospace, and oil and gas. In the automotive sector, they are commonly used in engine assemblies, transmissions, and fuel systems, where maintaining a leak-free environment is crucial for performance and safety. Similarly, in the aerospace industry, bonded seal rings are employed in hydraulic systems and fuel tanks, where the integrity of seals directly impacts the performance and reliability of aircraft.

In the oil and gas industry, bonded seal rings are essential for ensuring seals in drilling equipment and pipelines. The ability to withstand harsh environments, including extreme temperatures and corrosive substances, makes them invaluable for preventing leaks that could lead to severe environmental and financial consequences.

Conclusion

In conclusion, bonded seal rings are indispensable components in modern industrial applications. Their unique design, combining the strengths of metal and elastomer materials, allows them to provide reliable seals in a wide range of demanding environments. By preventing leaks and ensuring operational efficiency, bonded seal rings contribute significantly to the longevity and performance of machinery across various sectors. As industries continue to evolve and demand higher standards of reliability, the role of bonded seal rings in maintaining safety and efficiency will only grow more prominent. Therefore, investing in quality bonded seal rings is essential for manufacturers and industries looking to enhance their operational capabilities and ensure long-term success.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories