Exploring the Benefits and Applications of Bonded O-Rings in Industrial Settings and Sealing Solutions

The Importance of Bonded O-Rings in Industrial Applications

In the realm of industrial sealing solutions, bonded O-rings have emerged as a critical component for ensuring reliable performance in various applications. O-rings, as most engineers and technicians know, are simple toroidal shapes used to create a seal at the interface between two or more parts. However, bonded O-rings offer several advantages that make them particularly valuable in specific environments, particularly where heightened pressures, temperatures, or exposure to aggressive materials are involved.

What Are Bonded O-Rings?

Bonded O-rings are essentially standard O-rings that have been enhanced through a bonding process. This bonding often involves the integration of two or more elastomeric materials or the addition of a secondary material to improve performance. The result is a highly durable seal that can withstand a larger range of operating conditions than traditional O-rings. The bonding process can create a variety of formats, including dynamic and static seals, which can offer greater flexibility in design.

Advantages of Bonded O-Rings

1. Enhanced Durability The primary benefit of bonded O-rings is their increased durability. The bonding process enhances the resistance of the O-ring to wear and tear, making them suitable for high-pressure environments. Unlike conventional O-rings that may degrade under extreme conditions, bonded O-rings maintain their integrity, prolonging the lifespan of the seal and minimizing the need for replacements.

2. Improved Chemical Resistance In industries where exposure to harsh chemicals is common, bonded O-rings can be customized with materials that resist corrosive substances. This property is crucial for applications such as oil and gas, pharmaceuticals, and food processing, where chemical compatibility can directly impact the safety and efficacy of processes.

3. High-Temperature Performance Many bonded O-rings are engineered to withstand extreme temperatures, both hot and cold. This capability is essential in applications where thermal expansion must be managed, such as in automotive engines, aerospace components, and industrial machinery.

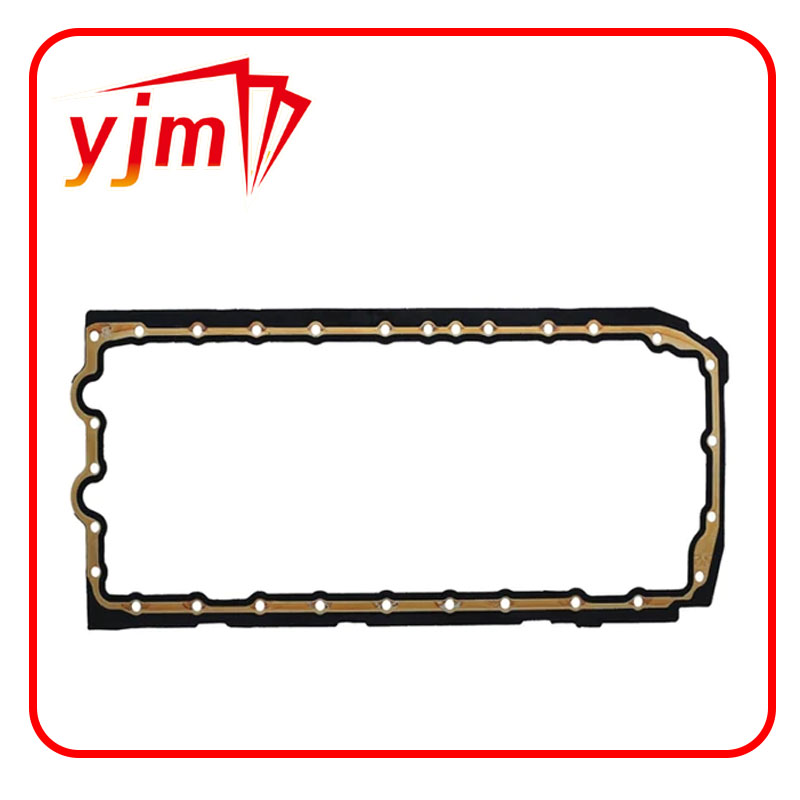

bonded o ring

4. Versatility in Design The ability to design bonded O-rings with varying dimensions and materials allows for greater versatility in applications. Engineers can tailor O-rings to fit specific design requirements while ensuring optimal sealing performance, which can lead to better overall efficiency in machinery and systems.

5. Ease of Installation Bonded O-rings can often be easier to install than traditional seals. Their enhanced structure reduces the likelihood of damage during installation, leading to time and cost savings for manufacturers and maintenance teams.

Applications of Bonded O-Rings

Bonded O-rings find their applications across various industries. In the automotive sector, they are used in fuel systems, oil seals, and coolant lines. In the aerospace industry, they provide essential sealing in hydraulic systems and fuel tanks. Additionally, in manufacturing equipment for food and beverage processing, bonded O-rings ensure that seals maintain integrity in hygienic environments, preventing contamination.

Moreover, the healthcare industry benefits from bonded O-rings in medical devices where sterile and reliable seals are imperative. With the ongoing advancements in material science, the future of bonded O-rings looks promising, with potential innovations allowing even further enhancements in performance.

Conclusion

In summary, bonded O-rings represent a significant advancement in sealing technology. Their durability, chemical resistance, and versatility make them an ideal choice for a wide array of industrial applications. As industries continue to evolve and demand greater efficiency and reliability, bonded O-rings will undoubtedly play a vital role in meeting these challenges. Understanding their benefits can help engineers and procurement teams make informed decisions that enhance overall operational reliability and safety.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories