engine hoist cylinder repair kit

Engine Hoist Cylinder Repair Kit Ensuring Optimal Performance for Lifting Applications

When it comes to heavy lifting in automotive repair or industrial settings, an engine hoist is a crucial piece of equipment. Engine hoists, commonly utilized to lift engines or heavy machinery, rely on hydraulic cylinders to provide the necessary power and stability. Over time, the wear and tear on these cylinders can lead to decreased efficiency and operational safety. This is where an engine hoist cylinder repair kit becomes indispensable.

An engine hoist cylinder repair kit typically includes all the essential components needed to restore a hydraulic cylinder to its peak performance. The kit generally contains seals, O-rings, wipers, and sometimes even replacement rods or pistons, allowing users to effectively address common issues such as leaks, decreased lifting capacity, and sluggish operation. Investing in a repair kit can be significantly more cost-effective compared to replacing the entire hoist, making it a smart choice for both professionals and DIY enthusiasts alike.

Importance of a Functional Hydraulic Cylinder

The hydraulic cylinder acts as the heart of an engine hoist. It converts hydraulic fluid pressure into mechanical force, allowing the hoist to lift heavy loads efficiently. However, with frequent use, components can become worn or damaged. A malfunctioning cylinder can lead to leaks, reduced lifting power, or even complete failure during operation, which poses serious safety risks. Regular maintenance and timely repairs using a dedicated cylinder repair kit can prevent these failures and enhance the longevity of the equipment.

Understanding the Components

Each component in a repair kit plays a vital role in the functionality of the hydraulic cylinder

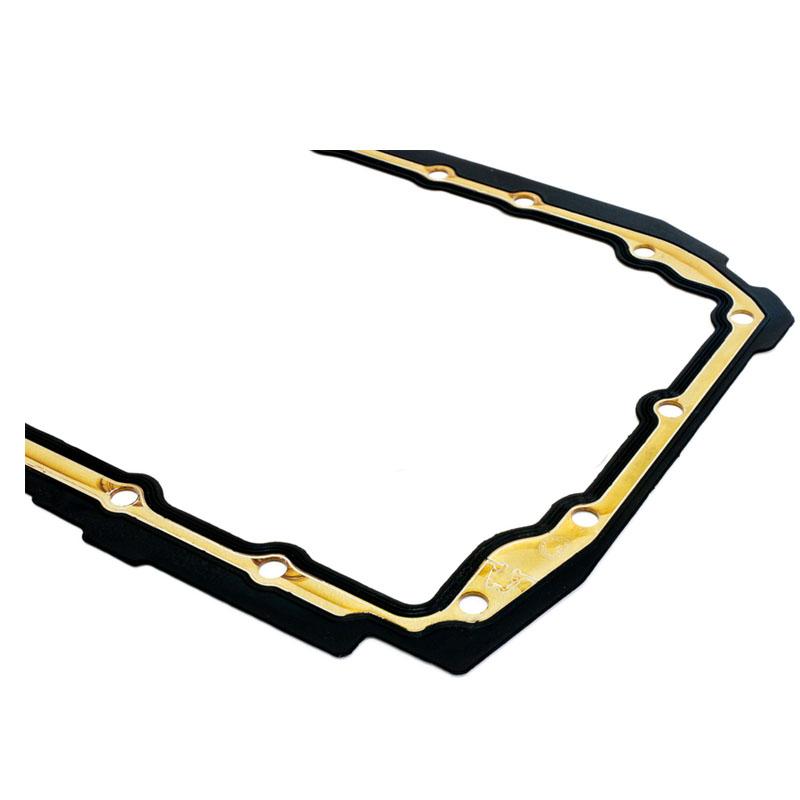

- Seals These are essential for preventing hydraulic fluid from leaking out of the cylinder. Worn seals can lead to pressure loss and inefficient operation. - O-Rings Similar to seals, O-rings are used to create a leak-proof barrier. They are crucial for maintaining pressure in the hydraulic system. - Wipers These help in preventing dirt and contaminants from entering the hydraulic cylinder, which can lead to further damage.

- Rod and Piston While not always included in every kit, having replacements for these components can be necessary for restoring full functionality if they become bent or worn.

Steps for Repair

engine hoist cylinder repair kit

Repairing a hydraulic cylinder using a repair kit typically involves the following steps

1. Disassembly Carefully remove the cylinder from the hoist and disassemble it according to the manufacturer's guidelines.

2. Inspection Examine all components for wear or damage. Replace any parts that are beyond repair.

3. Cleaning Thoroughly clean all parts, ensuring that any residue or debris is removed.

4. Replacement Install new seals, O-rings, and wipers as per the instructions provided in the repair kit.

5. Reassembly Reassemble the cylinder, ensuring that all parts are fitted correctly and securely.

6. Testing After reinstallation, conduct a thorough test of the hoist to ensure it operates smoothly and efficiently without leaks.

Conclusion

An engine hoist cylinder repair kit is an essential investment for anyone who regularly uses an engine hoist, whether in a professional garage or for personal projects. By addressing minor issues with hydraulic cylinders promptly, users can enhance the efficiency and safety of their lifting operations, ensuring that they can tackle any project with confidence. Regular maintenance and timely repairs will ultimately extend the life of your equipment and guarantee reliable performance when it matters most.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories