engine hoist cylinder repair kit

Engine Hoist Cylinder Repair Kit A Comprehensive Guide

An engine hoist is an essential piece of equipment in any automotive repair shop or for DIY mechanics who frequently work on vehicle engines. These robust tools lift heavy engines with precision and safety, making engine removal and installation much more manageable. However, like any mechanical device, an engine hoist can experience wear and tear over time, particularly in its hydraulic cylinder. To maintain performance and extend the life of your engine hoist, understanding how to effectively repair and service the hydraulic cylinder using a repair kit is crucial.

Understanding the Hydraulic Cylinder

The hydraulic cylinder is the heart of the engine hoist. It utilizes hydraulic fluid to create pressure that lifts heavy loads. When you pull the hoist’s lever, hydraulic fluid moves into the cylinder, pushing the piston upward. If any components of the hydraulic cylinder wear out, such as seals or O-rings, it can lead to fluid leakage and reduced lifting capacity. This is where the engine hoist cylinder repair kit comes into play.

What’s in an Engine Hoist Cylinder Repair Kit?

A typical engine hoist cylinder repair kit contains a variety of components designed to replace worn or damaged parts within the hydraulic system. Common parts included in the kit are

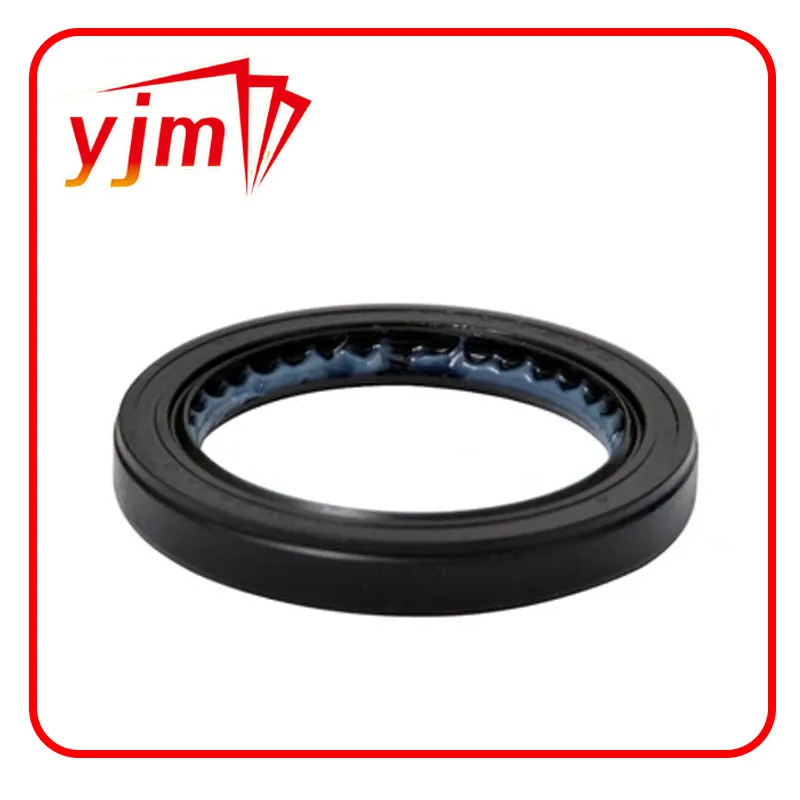

1. Seals These prevent hydraulic fluid from leaking out of the cylinder. They are typically made from rubber or synthetic materials that can withstand high pressures.

2. O-rings Small yet essential, O-rings are used to create a seal between two surfaces, ensuring that no fluid escapes during operation.

3. Piston Assembly If the piston becomes damaged or corroded, replacing it may be necessary to maintain proper function.

4. Dust Boots These protect the seals and piston from debris and contaminants that can cause premature wear.

5. Instruction Manual Most kits come with detailed instructions that guide you through the repair process step by step.

When to Use a Repair Kit

Recognizing when repair is needed is key to maintaining your engine hoist

. Symptoms of a failing hydraulic cylinder includeengine hoist cylinder repair kit

- Fluid Leaks Noticeable puddles of hydraulic fluid indicate a problem with seals or O-rings. - Reduced Lifting Capacity If your hoist struggles to lift as much weight as it used to, it may signal an issue with the hydraulic system. - Slow Operation A slow or jerky lifting motion can be a sign of internal wear.

Once you notice these symptoms, it's best to act quickly. Delaying repairs can lead to more severe malfunction and costly replacements.

How to Perform Repairs

1. Safety First Ensure the hoist is not in use and that any loads have been lowered completely. Disconnect the hoist from any power source.

2. Remove the Cylinder Carefully detach the hydraulic cylinder from the hoist by unscrewing the necessary bolts.

3. Disassemble the Cylinder Remove the piston from the cylinder. Pay attention to the order of disassembly for easier reassembly later.

4. Inspect Components Check all parts for signs of wear. If anything looks damaged beyond repair, replace it with new parts from the repair kit.

5. Replace Seals and O-Rings Remove the old seals and O-rings and install the new components from your repair kit. Ensure they are seated correctly to prevent leaks.

6. Reassemble the Cylinder Put the cylinder back together, carefully following the steps you took during disassembly.

7. Reattach the Cylinder Once the repairs are complete, reattach the cylinder to the hoist and ensure all bolts are tightened.

8. Test the Hoist Before heavy use, perform a test operation without any load to ensure everything functions smoothly.

Conclusion

Maintaining your engine hoist is crucial for safety and efficiency in any mechanical workshop. Investing in a quality engine hoist cylinder repair kit can save you time and money by allowing you to perform your own repairs and upkeep. By recognizing the signs of wear and following a straightforward repair process, you can keep your engine hoist in prime working condition for years to come, ensuring smooth engine installations and removals for all your automotive projects.

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

-

The Importance of Heavy Duty Seals in Industrial and Residential Applications

News Jul.30,2025

-

Exploring Industrial Oil Seals: From Felt Oil Seals to TTO and CFW Solutions

News Jul.30,2025

-

Essential Guide to Oil Seals: From Radial to Metal-Cased Seals for Industrial Reliability

News Jul.30,2025

-

Choosing the Right Oil Seals and Gaskets for Industrial and Automotive Applications

News Jul.30,2025

-

Cassette Seals: Durable Sealing Solutions for Harsh Environments

News Jul.30,2025

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

Products categories