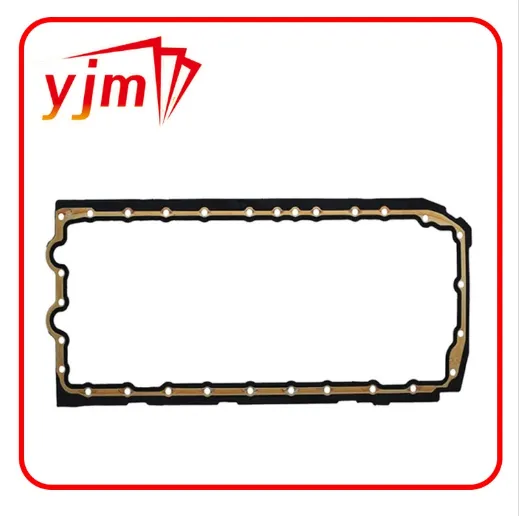

end cap oil seal

Evaluating the performance of end cap oil seals also encompasses understanding their role in reducing maintenance costs and downtime. The proper selection and installation of these seals lead to fewer machinery interruptions, directly contributing to increased operational efficiency. This aspect resonates well with engineers and maintenance professionals who prioritize operational uptime and cost-efficiency. Technical training and field experience significantly contribute to the comprehension of seal installation methodologies, facilitating optimal performance. A crucial factor in the trustworthiness of end cap oil seals lies in their field performance evaluations and customer testimonials. Real-world applications and user reviews provide insights into the seals’ durability and resilience, offering prospective buyers a basis for informed decision-making. The collaborative feedback loop between engineers and end-users aids in the constant refinement and enhancement of seal technologies, reassuring stakeholders of the product's reliability. In conclusion, end cap oil seals are an indispensable component in numerous mechanical systems. Their ability to prevent leaks and contamination, coupled with their adaptability to various operational contexts, underscores their value in industrial applications. By adhering to international standards and leveraging advanced materials, end cap oil seals assure extended machinery life and reduced operational costs. Professionals equipped with knowledge of material properties, application requirements, and installation techniques will undoubtedly appreciate the crucial function these seals perform in sustaining machinery integrity and performance.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories