Durable Mechanical Oil Seals for Enhanced Performance and Protection in Industrial Applications

Understanding Mechanical Oil Seals Importance, Types, and Applications

Mechanical oil seals are crucial components in various machinery and equipment, designed to prevent the leakage of lubricants while keeping contaminants out. They play an essential role in maintaining the integrity and efficiency of mechanical systems, thereby extending equipment life and enhancing performance.

Importance of Mechanical Oil Seals

Mechanical oil seals are used extensively in automotive, aerospace, industrial, and marine applications. Their primary function is to retain lubricating oils within a system while preventing dirt, dust, and moisture from entering. This is vital in maintaining optimal lubrication, reducing friction, and preventing wear and tear on moving parts. A malfunctioning oil seal can lead to lubricant leakage, which not only causes operational inefficiencies but can also result in severe damage to machinery components.

Moreover, oil seals contribute to environmental protection by reducing the risk of oil spills and leaks, thus minimizing the impact of operations on surrounding environments. Implementing robust oil seals can lead to significant cost savings associated with maintenance and repairs, along with enhancing the reliability of equipment.

Types of Mechanical Oil Seals

Mechanical oil seals come in a variety of types, designed for specific applications. The most common types include

1. Rotary Oil Seals Also known as lip seals, these are designed for rotating shafts. They typically feature a flexible lip that makes contact with the shaft, creating a tight seal to prevent leakage.

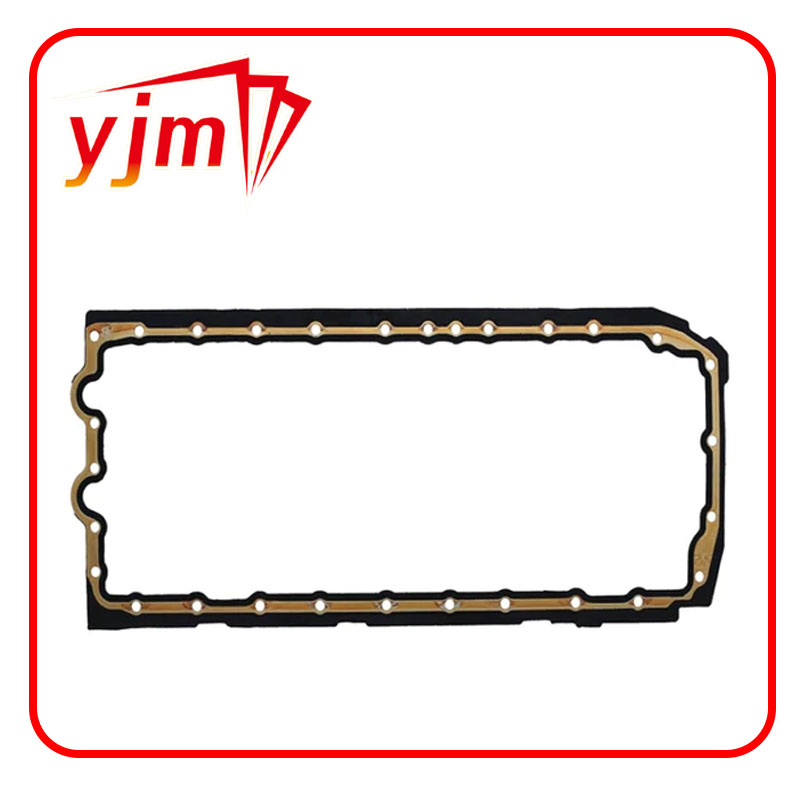

2. Flat Oil Seals These seals are often used in applications where the seal is applied to a flat surface, providing a reliable barrier against oils and fluids.

3. Spherical and Conical Oil Seals These are designed to adapt to various shapes and can be used in applications where conventional seals may fail due to design constraints.

mechanical oil seals

5. Double Lip Seals These seals have two sealing lips to provide an additional layer of protection against contaminants, making them suitable for harsh environments.

Materials Used in Oil Seals

The effectiveness of mechanical oil seals largely depends on the materials used in their construction. Common materials include rubber, elastomers, and thermoplastics, which provide flexibility and resilience. More specialized materials like fluorocarbon and silicone rubber are utilized in high-temperature applications or when chemical resistance is needed.

The choice of material should be based on the application requirements, including temperature, pressure, and the type of fluids being sealed. Proper material selection ensures that the seals maintain their integrity over long periods, even under challenging conditions.

Applications of Mechanical Oil Seals

Mechanical oil seals are found in numerous applications across various industries. In the automotive sector, they are used in engines, transmissions, and differentials. In industrial machinery, they are crucial in pumps, compressors, and gearboxes. The aerospace industry relies on these seals to protect critical components in engines and hydraulic systems.

In addition to these applications, mechanical oil seals are essential in household appliances and equipment, where they help in maintaining operational efficiency and prolonging the lifespan of products.

Conclusion

In conclusion, mechanical oil seals are vital components that ensure the longevity and efficiency of mechanical systems across various industries. Understanding their importance, the types available, the materials used, and their diverse applications can aid in the proper selection and maintenance of these seals, ultimately leading to improved performance and reduced operational costs. Whether in a car engine or industrial machinery, the reliability that mechanical oil seals offer is indispensable in today's technology-driven world.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories