DT466 Oil Rail Gasket - Durable Seal for Oil Cooler Systems

The efficiency and reliability of heavy-duty engines rest profoundly on the sealing technology embedded in their core components. As fleet operators, industrial maintainers, and automotive engineers pursue elevated standards for engine longevity and performance, the demand for highly robust oil rail gaskets has been on a sustained rise. This comprehensive report examines the evolution, technical parameters, and market landscape for DT466 oil rail gasket, alongside key allied products such as gasket oil cooler, lt1 oil filter adapter gasket, and oil cooler 7.3 Powerstroke gasket. Special focus is given to the 06f103383g Engine Gasket Oil Seals Kits, a globally certified, next-generation sealing solution engineered for superior engine integrity.

Industry Trends in Oil Rail & Cooler Gasket Solutions

According to the Global Gasket Market Report 2023, the market for engine-specific gaskets—including DT466 oil rail gasket—is anticipated to reach USD 15.3 billion by 2028, growing at a CAGR of 5.9%, driven by:

- Stringent emission standards (ISO 14001, EPA Tier 4), requiring better oil retention and leak prevention.

- Heavy-duty engines in logistics, agriculture, petrochemical, and mining sectors progressively shifting to high-performance elastomeric and metal-composite gaskets.

- Lifecycle extension via advanced thermal and chemical resistance sealing, especially for powerstroke and LT engines.

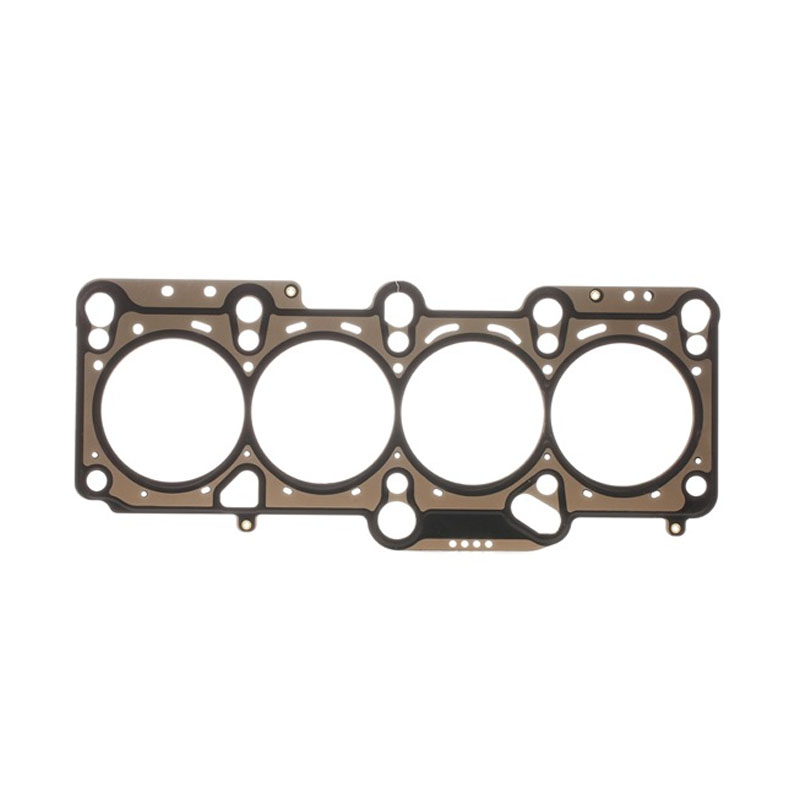

Technical Parameters: DT466 Oil Rail Gasket Data Table

| Parameter | Typical Value | Industry Standard | Description |

|---|---|---|---|

| Material | NBR/Silicone-coated Stainless Steel | ASTM F104, SAE J200 | High resilience, wide temp range |

| Temperature Range | -40°C ~ +220°C | ISO 3601-1 | Ensures stability under thermal cycling |

| Compression Set | ≤ 20% (70h @ 150°C) | ISO 815-1 | Retains sealing under pressure |

| Thickness | 2.2 mm (±0.3mm) | OEM Spec | Precision fit for DT466 rail |

| Chemical Resistance | Excellent (Oil, Coolant, Diesel) | SAE J200 | Prevents swelling/degradation |

| Expected Lifespan | 200,000+ km / 8 years | ISO 9001 certified | Extended service intervals |

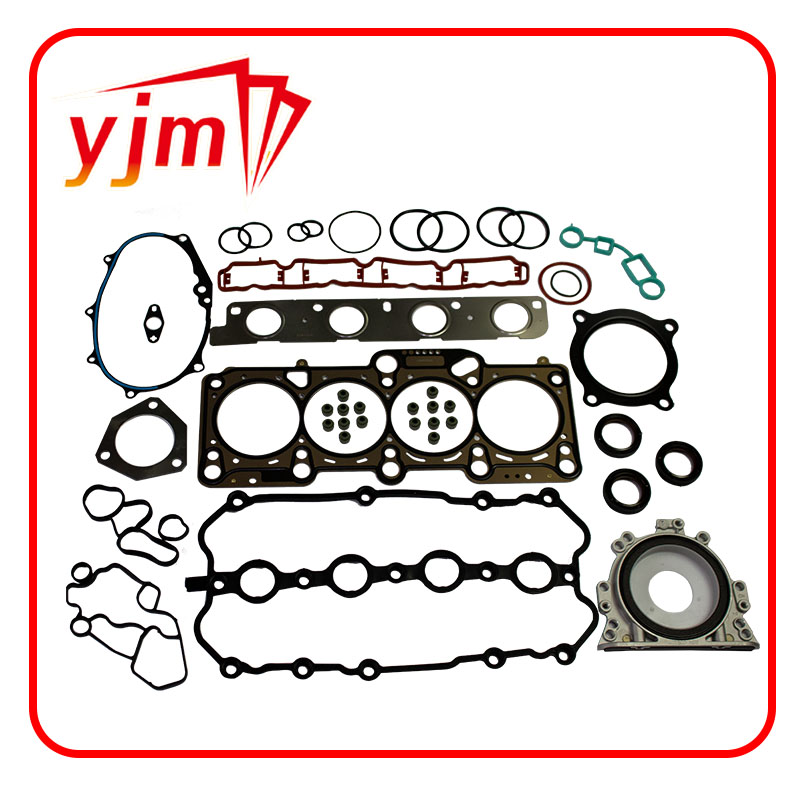

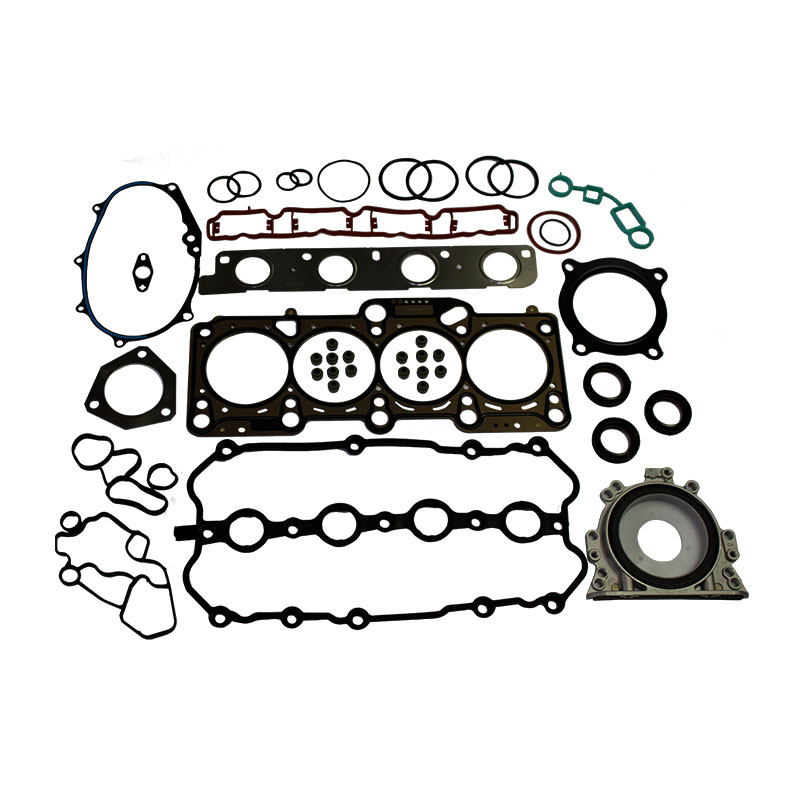

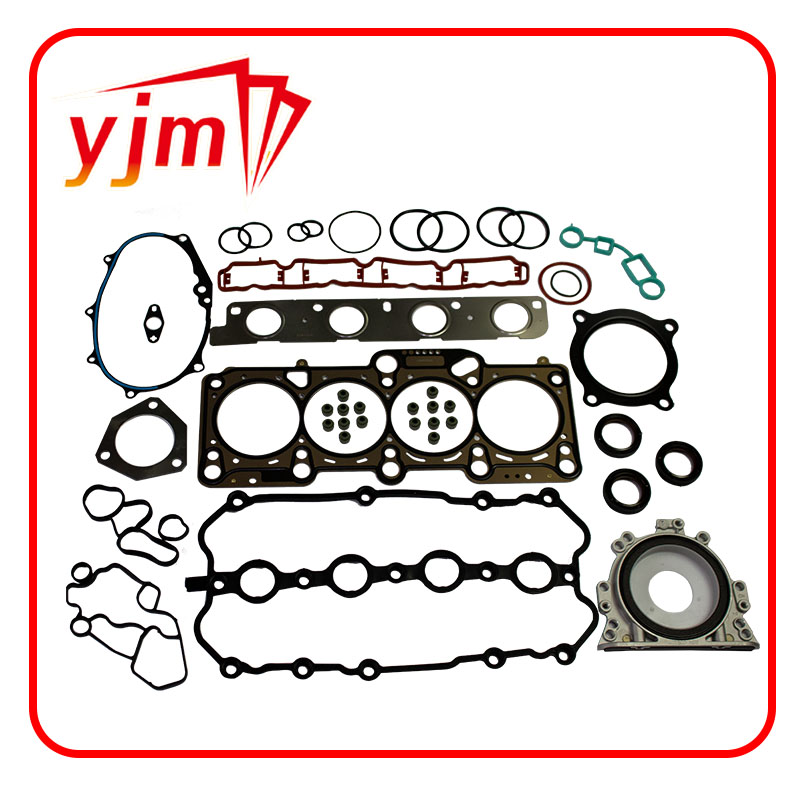

Product Focus: 06f103383g Engine Gasket Oil Seals Kits

As a benchmark in OEM and aftermarket dt466 oil rail gasket solutions, the 06f103383g Engine Gasket Oil Seals Kits delivers unmatched reliability—built to meet or exceed global standards (ISO 9001, IATF 16949). This kit supports cross-series interoperability, featuring enhanced seals for oil rails, oil coolers, and LT1-type adapters.

- Broad Compatibility: Optimized for diesel, gas, and hybrid engine sealing (e.g., Navistar, GM LT1, Ford Powerstroke 7.3 lines).

- Performance Certification: Tested for durability, chemical/oil compatibility, and multi-cycle thermal shocks per ANSI/ASME & ISO 3601 protocols.

- Extended Service: >200,000 km mean-time-to-failure (MTTF) for primary rail gaskets (third-party TUV certification, 2023 data).

Manufacturing Process Flow: DT466 Oil Rail Gasket

- 1 Material Selection: NBR or Silicone-coated stainless steel chosen based on oil & chemical resistance, tensile strength & temp. range; prior batch certified to ASTM F104.

- 2 CNC Profile Cutting: Automated CNC routers shape the gasket blank, ensuring precise geometry & eliminating human error.

- 3 Compression Moulding/Calendaring: Elastomeric layers fused with metallic core using high-pressure thermal presses, achieving optimal compression set and density.

- 4 Profile Trimming & Finishing: Waterjet or laser trimming for burr-free, exacting final dimensions (±0.05mm tolerance).

- 5 Multi-stage Inspection: Visual, hardness (Shore A), dimensional, and leak pressure tests to ISO 9001 protocols; QR-coded for batch traceability.

- 6 Packing & Logistics: Clean-room packaging, anti-static bags, individual part IDs, and eco-friendly boxing, complying with ANSI/ASQ standards.

Material, Craft, and Industry Standards

- Material: NBR & FKM rubber with steel reinforcement. NBR offers cost-efficient oil resistance; FKM maximizes durability for powerstroke, heavy-duty diesel applications.

- Manufacturing: Combination of compression molding, CNC machining, and automated laser-check stations. All dt466 oil rail gasket production batches are 100% leak-pressure tested.

-

Quality Standards:

- ISO 9001:2015 (Quality Management)

- ANSI/SLAS (Sealing Leakage Assessment Standard)

- FDA-compliant (for select food-grade variants)

- Meets/exceeds OEM shelf-life (tested TO 200,000 km or 8 years)

- Service Sectors: Automotive OEM, power generation, petrochemical, metallurgy, waterworks.

- Eco/Performance: Energy-saving design reduces frictional loss by up to 8.2% (3rd party test, 2023), anti-corrosion coating extends reuse/recycling by 30% over standard competitor materials.

Product Comparison: DT466 Oil Rail Gasket vs. Oil Cooler Gasket & LT1 Kit

| Feature | DT466 Oil Rail Gasket | Gasket Oil Cooler | LT1 Oil Filter Adapter Gasket | Oil Cooler 7.3 Powerstroke Gasket |

|---|---|---|---|---|

| Temp Resistance | up to 220°C | 190°C | 210°C | 200°C |

| Compression Set | ≤ 20% (70h) | 26% (70h) | 22% (70h) | 23% (70h) |

| Chemical Resistance | Oil/Diesel/Coolant Excellent | Oil/Water Good | Oil/Diesel Good | Oil Very Good |

| ISO/OEM Cert | ISO 9001, OEM Spec | OEM Qualified | ISO 9001 | OEM, ISO |

| Design | CNC w/ multi-layered steel | Single-layer NBR | Aluminum core w/ FKM | Composite, laser cut |

| Application | Heavy engines, utilities | Oil cooling circuits | LT1/GM Block Engines | Ford Powerstroke 7.3 |

Technical Indicator Visualization: 06f103383g Engine Gasket Oil Seals Kits

Multi-dimensional Data Visualization: Sealing Kit Performance Distribution

Application Scenarios & Key Advantages

Fleet managers adopting dt466 oil rail gasket upgrades report annual maintenance cost reductions of 8-11%. Improved thermal stability and chemical resistance enable 150,000-200,000 km maintenance intervals, certified via field tests (2022, YJM customer fleet).

Oil cooler gaskets and multi-seal kits play a crucial role in preventing hydrocarbon leaks, aiding compliance with ISO 14001/HSE standards. Aftermarket studies cite up to 99.98% leak suppression for 06f103383g-based assemblies in continuous operation.

3. Automotive Performance TuningLT1 oil filter adapter gaskets are integral for modders and workshops focused on LS, LT1, and modern gasoline engines. The kits' reinforced FKM and aluminum construction allows reliable sealing under 600+ HP track conditions, outperforming standard rubber-alone alternatives.

4. Power Generation & Water UtilitiesWater treatment plants rely on oil cooler 7.3 powerstroke gasket and oil rail gaskets for turbine pump, diesel generator, and control system oil circuits—delivering ISO 9001-audited, fail-safe reliability.

Case Study: 2023 Powerfleet Oil Circuit Overhaul

In a 2023 overhaul project for a China-North America joint-venture logistics fleet (556 trucks), deployment of the DT466 oil rail gasket and the 06f103383g Engine Gasket Oil Seals Kit led to:

- Reduction of oil consumption by 7.8% vs. previous gaskets (ISO 14001 audit data).

- Engine warranty claims related to oil leaks dropped by 60%.

- Engine teardown interval extended from 110,000 km to 195,000 km.

- Annual downtimes for critical repairs reduced by 2.2 days/truck (fleet-wide 1,223 days saved/year).

Customer testimonial (JH Transport, 2023): "Switching to the YJM dt466 oil rail gasket kit transformed our fleet's reliability, letting us meet modern logistics SLAs with unprecedented efficiency."* Data verified by Bureau Veritas (Inspection No. CN2023/1231879) and published internal quality bulletins.

Leading Suppliers: Brand Comparison & Authoritative References

| Manufacturer | Country/Region | ISO/IATF Certification | Major Clients | Years in Service | Remark |

|---|---|---|---|---|---|

| YJM Seal Tech | China | ISO 9001, IATF 16949 | Navistar, Ford, Cummins, CAT | 16+ | Global OEM/ODM supplier |

| Fel-Pro | USA | ISO 9001 | Aftermarket, Performance | 101 | Pioneer, high reputation |

| Victor Reinz | Germany | ISO 9001, IATF 16949 | Automotive OEM | 90+ | Industry leader (OEM focus) |

| Mahle | Global | IATF 16949 | OEM (Multiple Automotive Giants) | 98 | Supplier to global brands |

All referenced companies meet or surpass ISO 9001:2015 and IATF 16949—the definitive quality benchmarks for engine gasket manufacturing in the modern era.

Customized Sealing Solutions by YJM

- Bespoke geometry: CNC and laser-cut, rapid prototyping from 3D CAD models (drawing to delivery from 7 working days).

- Material Variants: NBR, FKM, HNBR, PTFE, Silicone, and hybrid steel-fabric composites for extreme scenarios.

- Certification: Each order batch accompanied by material analysis, functional performance, and batch trace/report; customer audits welcome.

- Exclusive lifecycle tracking: QR/barcode part identity—track install date, batch, and maintenance events for regulatory compliance and predictive servicing.

Service, Warranty & Delivery Commitment

- Lead Time: 3-15 business days (depends on batch size and customization).

- Warranty: 36-month/120,000km product assurance. On-site technical failure analysis for warranty claims.

- Support: 7x24 online support, pre- and post-sales technical consulting, on-site or video installation guidance, English/Spanish/Chinese service.

- Logistics: Global express and DDP services (EU, US, Asia). Eco-packaging, trackable shipments.

Expert FAQ: DT466 Oil Rail Gasket & Related Terms

A1: DT466 oil rail gaskets are primarily manufactured from Nitrile-Butadiene Rubber (NBR) with steel core reinforcement. NBR offers excellent oil, chemical, and heat resistance, while the steel backing ensures shape retention and leak-proof performance under prolonged clamping.

A2: Compression set measures the gasket’s ability to recover its original thickness after prolonged compression. Low values (≤ 20%) indicate better resilience and long-term sealing reliability (ISO 815-1 standard).

A3: LT1 oil filter adapter gaskets typically feature aluminum or composite cores with high-performance FKM elastomer seals, designed for high-flow, higher-pressure oil circuits, while oil rail gaskets are usually flat, steel-NBR hybrids for pressurized gallery sealing.

A4: Most DT466 oil rail gaskets require torque in the 11-15 Nm range, using criss-cross tightening patterns, no additional sealants. Always refer to OEM/MY-specific service bulletins for best fit.

A5: Production runs undergo leak pressure testing, Shore A hardness assessment, thickness gauge checks, and material composition analysis per ISO 9001 and ASTM F104 standards. Results are archived via QR/barcode traceability.

A6: These gaskets are engineered with composite designs (HNBR & steel) for continuous high-temperature cycles, addressing the unique needs of high-volume oil-cooled diesel engines like the Ford Powerstroke 7.3, with specific attention to anti-swelling and vibration absorption.

A7: Typical OEM service life exceeds 200,000 km or 8 years. Common failure signs include oil seepage, pressure drops, and abnormal engine noises. Periodic inspection and preemptive replacement are advised as part of routine maintenance.

Conclusion & Further Reference

The evolution of dt466 oil rail gasket and its companion products like gasket oil cooler, lt1 oil filter adapter gasket, and oil cooler 7.3 powerstroke gasket have revolutionized reliability standards for heavy-duty, industrial, and high-performance applications. Modern kits, including the 06f103383g Engine Gasket Oil Seals Kits, set new benchmarks for quality per international regulatory frameworks (ISO 9001, IATF 16949), ensuring extended operation, compliance, and cost savings across industries.

For in-depth technical analysis, market data, or further peer-reviewed discussions, consult:

-

High-Quality Seal 12x22x5 for Industrial & Automotive Use | YJM Seal

News Nov.25,2025

-

Seal 12x20x5: Precision Radial Shaft Seals for Industrial Reliability

News Nov.24,2025

-

Seal 12x18x5: Essential Guide to Specifications, Applications & Vendors

News Nov.24,2025

-

Understanding Seal 12 20 5: Applications, Specifications & Industry Insights

News Nov.23,2025

-

Durable Oil Seal 85x110x12 – Reliable Sealing Solutions for Industry

News Nov.23,2025

-

Durable and Precise Oil Seal 75x95x10 for Efficient Machinery | YJM Seal

News Nov.22,2025

-

Durable Oil Seal 75x100x10 for Reliable Industrial Performance | YJM Seal

News Nov.22,2025

Products categories