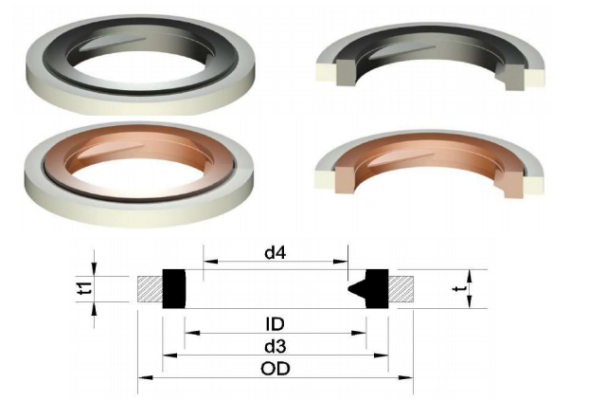

drain bolt washer

The Importance of Drain Bolt Washers in Mechanical Systems

In the world of mechanical engineering, precision and reliability are paramount. One often-overlooked component that plays a critical role in maintaining the integrity of mechanical systems is the drain bolt washer. While it may appear to be a simple, inconspicuous part, the function and importance of a drain bolt washer are indispensable for any system that involves fluids, particularly in automotive, aerospace, and industrial applications.

What is a Drain Bolt Washer?

A drain bolt washer is a type of sealing washer placed under the head of a drain bolt, which is used to close the drain hole in various machinery. This component serves a dual purpose it not only seals the joint to prevent fluid leaks but also acts as a cushioning surface to protect the threaded areas around the drain hole from damage. Typically made from materials like rubber, cork, or metal, drain bolt washers are designed to withstand specific pressures and temperatures depending on their application.

Importance of Drain Bolt Washers

1. Leak Prevention The primary function of a drain bolt washer is to prevent fluid leaks. In automotive engines, for instance, oil is crucial for lubrication. A worn or damaged washer may lead to oil leaks, resulting in decreased efficiency and eventual engine failure. Preventing such leaks is essential not only for the longevity of the system but also for environmental considerations, as leaked fluids can be harmful to the ecosystem.

2. Vibration Absorption Machinery often experiences vibrations during operation. A properly installed drain bolt washer can absorb some of this vibration, protecting the integrity of the threaded connection. This function is particularly important in high-performance engines or complex machinery where vibrations can cause fatigue over time.

3. Ease of Maintenance When it comes to routine maintenance, drain bolt washers simplify the process of fluid changes. The sealing capability of the washer ensures that fluid can be drained and replaced without significant mess or leakage, making the maintenance process more efficient and less time-consuming.

drain bolt washer

4. Corrosion Prevention Many drain bolt washers are designed with corrosion-resistant properties, which help to protect the drain bolt and the surrounding area from rust and degradation. This is especially crucial in environments where machinery is exposed to moisture or harsh chemicals. Selecting the right material for the washer can significantly enhance the longevity of the components involved.

Choosing the Right Drain Bolt Washer

Selecting the appropriate drain bolt washer for your application is vital. Consider the following factors

- Material Compatibility The washer material should be compatible with the fluid it will be sealing against. For example, petroleum-based oils require a different type of washer than water-based fluids.

- Temperature and Pressure Ratings It is crucial to choose a washer that can withstand the operating temperature and pressure of the system. High-performance scenarios may require specialized materials that can hold up under extreme conditions.

- Size and Fit The washer must fit precisely under the drain bolt. A washer that is too small or too large may not provide an adequate seal, leading to potential leaks.

Conclusion

In summary, drain bolt washers may seem like a minor detail in the vast spectrum of mechanical engineering, but their importance cannot be overstated. They serve essential functions in sealing, cushioning, and protecting mechanical systems across various industries. The selection of the appropriate washer based on material compatibility, temperature, pressure ratings, and size is crucial for the optimal performance and longevity of machinery. By paying attention to these seemingly small components, engineers and technicians can ensure that their systems operate smoothly and efficiently, ultimately leading to better performance and reduced maintenance costs. So, the next time you find yourself working on a mechanical system with a drain bolt, remember the vital role that the unassuming drain bolt washer plays in ensuring the overall health and efficiency of that system.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories