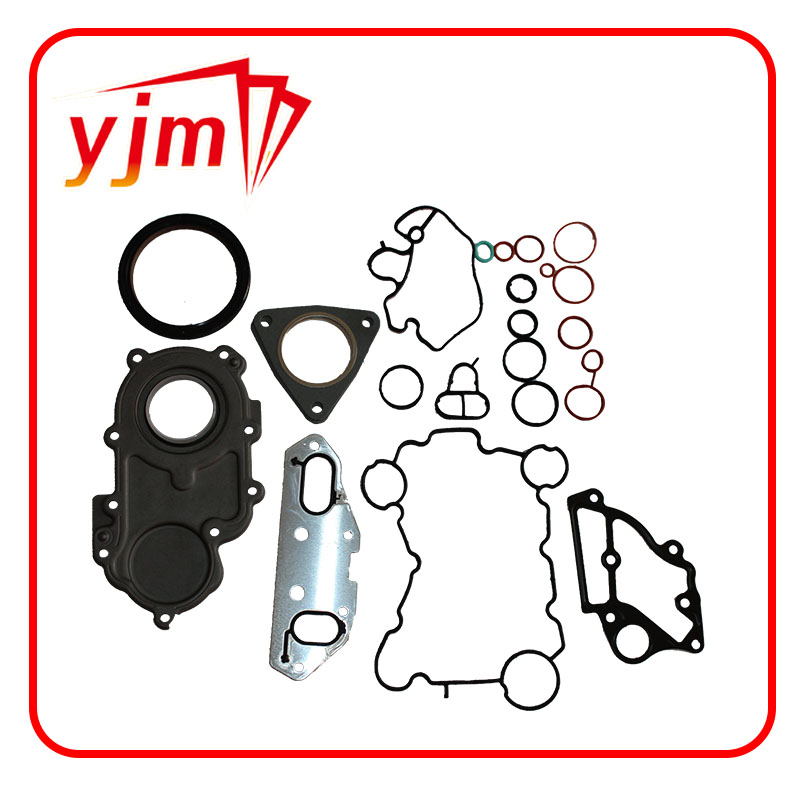

drain bolt washer

Understanding the Importance of Drain Bolt Washers

When it comes to maintaining the integrity of various mechanical systems, the smallest components often play the most critical roles. One such unsung hero is the drain bolt washer. Used in a wide range of applications from automotive to marine and industrial machinery, these washers are essential for ensuring that connections remain sealed and free from leaks. In this article, we will delve into what drain bolt washers are, their types, and why they are vital in mechanical systems.

What is a Drain Bolt Washer?

A drain bolt washer is a type of sealing washer that is placed between a drain bolt and the surface it is securing. Its primary function is to create a tight seal that prevents the escape of fluids, whether it be oil, water, or other substances. This is crucial in systems where leakage could lead to significant problems, such as reduced efficiency, environmental hazards, or mechanical failure.

Types of Drain Bolt Washers

Drain bolt washers come in various materials and designs, catering to different requirements based on the application

. The most common materials include1. Copper Washers – Known for their excellent thermal conductivity and ability to withstand high temperatures, copper washers are often used in applications where heat is a concern. They provide a good seal and are reusable after annealing.

2. Rubber Washers – These washers offer flexibility and are typically used in systems where vibrations are present. Rubber is particularly good for providing a watertight seal but may not withstand high temperatures or aggressive chemicals.

3. Plastic Washers – Lightweight and resistant to corrosion, plastic washers are often used in applications where chemicals are present. They are effective in preventing leaks but may not be suitable for high-load applications.

drain bolt washer

4. Aluminum Washers – Aluminum offers a good balance of weight and strength, making it suitable for various mechanical systems. It is less expensive than copper and can be used in many automotive applications.

Each type of washer serves its own purpose, and choosing the right one for the specific application is crucial for optimal performance.

Why Are Drain Bolt Washers Important?

1. Preventing Leaks – The primary function of a drain bolt washer is to prevent leaks. In automotive systems, for example, leaking oil can lead to severe engine damage, decreased performance, and costly repairs. In marine applications, leaks can cause environmental damage and compromise the vessel's integrity.

2. Maintaining Pressure – In pressurized systems, washers help maintain the necessary pressure levels within the system. A failed seal can lead to decreased efficiency and operational problems.

3. Extending Component Life – By providing a reliable seal, drain bolt washers can help extend the life of mechanical components. Reducing exposure to fluids can prevent corrosion, wear, and other forms of degradation, thereby enhancing the longevity of machinery.

4. Cost-Effectiveness – Using the appropriate washer can save money in the long run. While washers are small and relatively inexpensive, the costs associated with leaks and subsequent repairs can be significant. Investing in high-quality drain bolt washers can mitigate these risks.

Conclusion

The drain bolt washer may seem like a minor component, but its importance cannot be overstated. Properly functioning drain bolt washers are essential for preventing leaks, maintaining pressure, and extending the life of mechanical systems. When working on any machinery or vehicle, it is vital to choose the appropriate type of washer based on the specific requirements of the application. By doing so, you ensure the reliability and efficiency of the system, steering clear of potential headaches in the future. Investing time and resources in selecting the right drain bolt washer is certainly a small endeavor with significant benefits.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories