double lip shaft seal

Understanding Double Lip Shaft Seals Design, Function, and Applications

Double lip shaft seals are essential components in various mechanical systems, specifically designed to prevent the leakage of fluids or lubricants while simultaneously keeping contaminants out. Their unique design and functionality make them highly valuable in industries ranging from automotive to aerospace and manufacturing.

Design and Structure

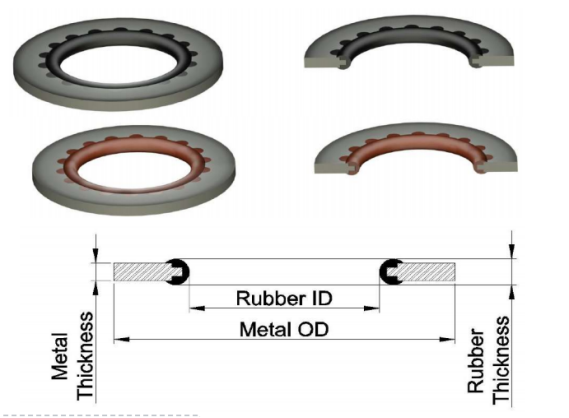

A double lip shaft seal typically consists of two elastomeric sealing lips, which work in conjunction to provide enhanced sealing performance. The primary lip is responsible for keeping lubricants in and preventing them from leaking out, while the secondary lip serves to block contaminants like dust, dirt, and moisture from entering the system. This dual-action mechanism significantly increases the overall effectiveness of the seal compared to single-lip designs.

The materials used in double lip seals are often resistant to wear, temperature fluctuations, and various chemical compounds, particularly oils and fuels. Common materials include nitrile rubber, fluorocarbon elastomers, and silicone, which can be selected based on the specific operating environment and requirements.

Functionality

The primary function of a double lip shaft seal is to retain lubrication and protect moving parts from external elements. By maintaining a proper lubricant level, the seal helps ensure efficient operation and prolongs the lifespan of machinery and equipment. Moreover, by preventing leakage, the seal minimizes waste and contributes to environmental protection by reducing fluid pollution.

double lip shaft seal

Another essential function of double lip seals is to mitigate wear and tear on the shaft. When contaminants infiltrate a system, they can lead to increased friction and ultimately, system failure. The effective sealing provided by double lip seals helps maintain a clean environment inside the assembly, enhancing performance and reliability.

Applications

Double lip shaft seals find applications in various sectors. In the automotive industry, they are commonly used in components like wheel bearings, transmission systems, and engine applications. Their ability to withstand harsh conditions and maintain performance under pressure makes them indispensable in maintaining vehicle reliability and efficiency.

In the manufacturing sector, equipment such as pumps, motors, and gearboxes frequently employ double lip seals to operate effectively. Protecting the internal components from contamination is crucial in these applications, where efficiency directly impacts productivity.

The aerospace industry also benefits from double lip seals due to their reliability in high-altitude and high-speed environments. Ensuring that mechanisms operate smoothly and without disruption is paramount for safety and performance in flight operations.

Conclusion

In summary, double lip shaft seals play a vital role in preventing fluid leakage and contamination across a wide range of applications. Their innovative design, coupled with durable materials, ensures optimal performance in demanding environments. Understanding their importance can help industries enhance operational efficiency, reduce maintenance costs, and increase the longevity of machinery, making double lip shaft seals integral to modern mechanical systems. As technology advances, so does the design and performance of these seals, promising even greater efficiency and reliability in the future.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories