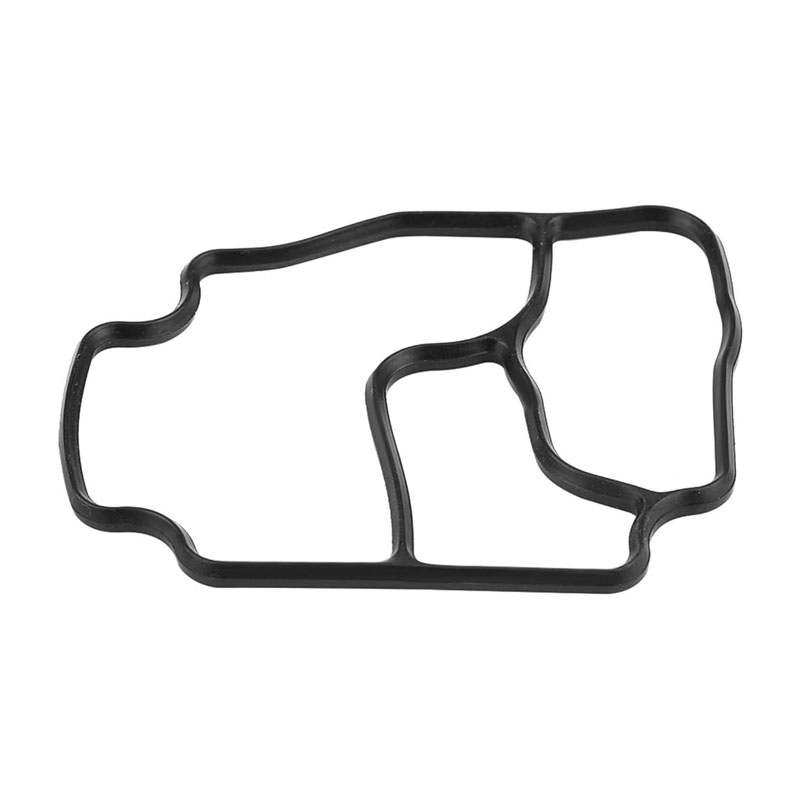

double lip oil seal

The Double Lip Oil Seal An Essential Component in Mechanical Engineering

In the realm of mechanical engineering, ensuring the integrity of moving parts is crucial for the functionality and longevity of machinery and equipment. One of the key components that plays a significant role in achieving this is the oil seal, specifically the double lip oil seal. This article will explore the design, functionality, applications, and advantages of double lip oil seals in various industries.

Understanding the Design

A double lip oil seal, as the name suggests, features two sealing lips instead of just one. This design enhances its ability to prevent fluid leakage, making it particularly useful in applications where lubrication is involved. The outer circumference of the seal is typically installed in a housing or casing, while the inner edge wraps around a rotating shaft. The two lips work together to create a barrier that effectively limits the escape of oil and the ingress of contaminants such as dirt and water.

Functionality of the Double Lip Oil Seal

The primary function of a double lip oil seal is to maintain lubrication within rotating components, such as bearings and gears, while preventing contaminants from entering the system. The two lips create a hydrodynamic seal, which is beneficial for minimizing wear and tear on parts. When the shaft rotates, the first lip makes contact with the shaft surface, generating a sealing effect that keeps the oil contained. The second lip provides an additional layer of protection, further reducing the risk of leakage.

The effectiveness of the double lip design can also be attributed to the material used for the sealing lips, which is often rubber or a suitable elastomer. These materials are selected for their durability, flexibility, and resistance to wear, making them ideal for high-performance applications.

Applications Across Industries

Double lip oil seals are widely used across various industries due to their versatile nature

. Some common applications include1. Automotive Industry In vehicles, double lip oil seals are found in engines, differentials, and transmission systems. They ensure that lubricants remain contained while preventing dust and debris from entering critical components.

double lip oil seal

2. Industrial Machinery In manufacturing equipment, these seals are essential for maintaining the performance of rotating shafts and bearings, reducing maintenance needs, and extending the lifespan of machinery.

3. Aerospace Engineering In aviation, reliability is paramount. Double lip oil seals are employed in various systems, including hydraulic systems and landing gears, where they provide crucial sealing capabilities under demanding conditions.

4. Hydraulic and Pneumatic Systems In hydraulic cylinders and pneumatic actuators, double lip seals help maintain pressure while preventing leakage, thus enhancing efficiency and performance.

5. Marine Applications Ships and submarines make extensive use of double lip oil seals to protect against the harsh marine environment, preventing saltwater intrusion and ensuring the integrity of lubrication systems.

Advantages of Double Lip Oil Seals

The benefits of employing double lip oil seals are numerous. Firstly, the dual sealing mechanism dramatically decreases the likelihood of leaks, which can lead to catastrophic failures or costly maintenance. Secondly, their robust design allows them to withstand a variety of operational conditions, including temperature fluctuations and exposure to chemicals.

Additionally, the wear resistance of the materials used in double lip oil seals enhances the durability of machinery, leading to longer intervals between maintenance schedules. This is especially valuable in industries where downtime can result in significant financial losses.

Conclusion

In conclusion, the double lip oil seal is a vital component in mechanical systems, providing essential sealing capabilities that enhance performance and reliability. Its innovative design, coupled with its wide range of applications, underscores its importance across multiple industries. By investing in quality double lip oil seals, companies can ensure their machinery operates efficiently while minimizing the risk of leaks and mechanical failures. As technology and materials continue to evolve, the future of oil sealing solutions looks promising, paving the way for even more advanced applications.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories