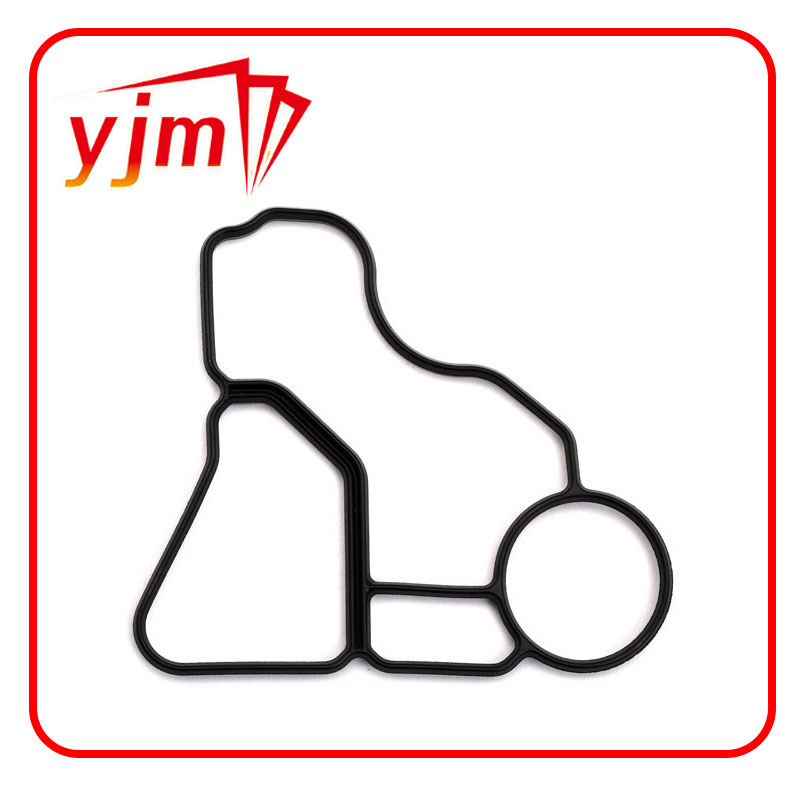

distributor oil seal

Understanding Distributor Oil Seals Importance, Types, and Maintenance

Distributor oil seals are often overlooked components of automotive machinery, yet they play a crucial role in the overall functioning of an engine. These seals serve to prevent oil leaks, which can lead to a range of problems if not addressed. In this article, we will explore the importance of distributor oil seals, the different types available, and some maintenance tips to ensure their longevity.

Importance of Distributor Oil Seals

The primary function of a distributor oil seal is to prevent oil from leaking out of the distribution system, particularly in engines where the oil is essential for lubrication and cooling. A good oil seal maintains the integrity of the oil compartment, ensuring that there is enough lubrication to protect moving parts from excessive wear and tear. When a seal starts to wear out, it may lead to oil leaks, which can quickly escalate into more serious issues such as engine overheating, loss of pressure, and costly repairs.

Moreover, a failing oil seal can contribute to environmental pollution, as leaking oil can contaminate soil and water systems. This not only poses a risk to local wildlife but can also result in significant fines for companies due to non-compliance with environmental regulations. Consequently, maintaining effective distributor oil seals is essential for both performance and environmental stewardship.

Types of Distributor Oil Seals

There are various types of distributor oil seals tailored to different automotive applications. The most common types include

1. Spring-loaded Seals These seals utilize a spring mechanism to apply consistent pressure against the shaft, ensuring a tight fit and preventing leaks. They are widely used in high-speed applications where dynamic sealing is essential.

2. Non-Spring Seals Unlike spring-loaded seals, these seals rely on material properties to create a seal. They are generally used in static applications where movement is limited.

3. Lip Seals This type features a flexible lip that creates a tight seal around a rotating shaft. Lip seals are highly effective in dynamic situations, making them a popular choice for automotive engines.

distributor oil seal

4. Rotary Seals Designed specifically for rotating applications, rotary seals can withstand both oil and dirt, making them ideal for harsh operating environments.

5. Custom Seals Some applications may require custom seals tailored to specific dimensions or materials for unique operating conditions.

Maintenance Tips

Regular maintenance of distributor oil seals is crucial to prolong their lifespan and maintain proper engine performance. Here are some tips

- Regular Inspections Periodically check your vehicle's oil levels and inspect for any signs of leaks. Early detection can save you from more severe problems down the line.

- Use Quality Oils Utilizing high-quality engine oil can reduce friction and wear on the seals, thus extending their lifespan.

- Temperature Management Ensure that the engine runs at optimal temperatures. High temperatures can cause seals to harden and crack, leading to potential leaks.

- Professional Servicing When doing major repairs that involve the distribution system, make sure to consult professionals who can ensure that seals are installed correctly and in good condition.

In conclusion, distributor oil seals are vital components in the automotive world that keep engines running smoothly and efficiently. By understanding their importance, types, and maintenance tips, vehicle owners can ensure that their engines remain in optimal condition, preventing costly repairs and promoting environmental responsibility. Remember, a small component like an oil seal can have a significant impact on the health of an engine and the environment, making it essential to prioritize their care.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories