Exploring Various Types of O-Rings and Their Applications in Different Industries

Different Types of O-Rings Understanding Their Applications and Materials

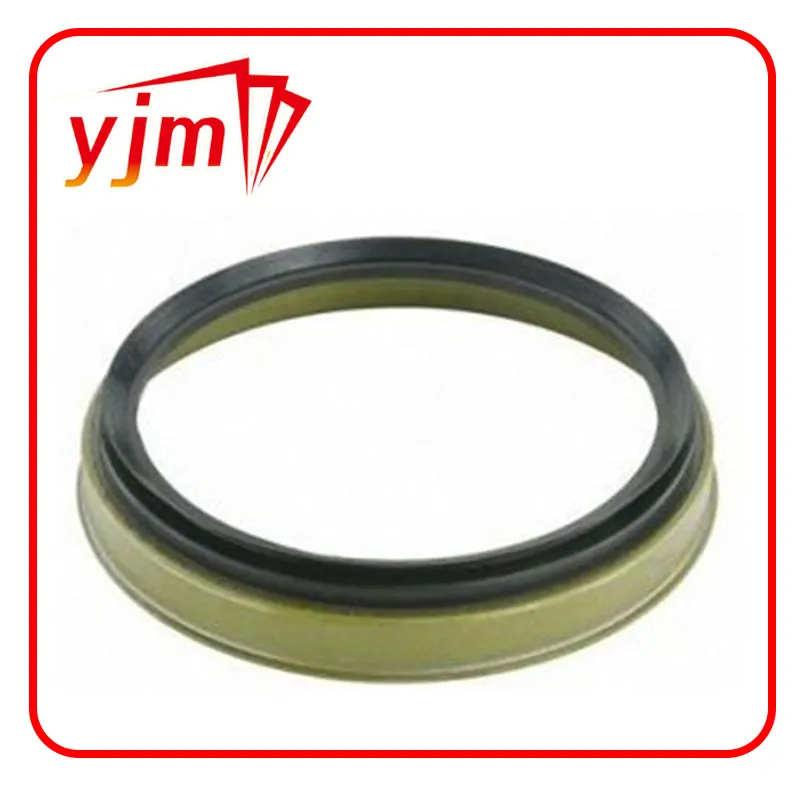

O-rings are versatile sealing devices widely used in various industries, including automotive, aerospace, manufacturing, and even household appliances. They are circular loops made of elastomeric materials that provide a reliable seal between two or more surfaces. This article will explore the different types of O-rings, discussing their materials, applications, and advantages.

Understanding O-Rings

An O-ring functions primarily as a mechanical seal. When compressed between surfaces, it creates a barrier that prevents the passage of fluids, gases, and contaminants. Their simplicity and effectiveness make them one of the most popular sealing solutions. However, the performance of an O-ring significantly depends on its material, size, and design.

Types of O-Rings Based on Material

1. Nitrile Rubber (Buna-N) O-Rings - Characteristics Nitrile rubber is the most commonly used material for O-rings. It offers good resistance to oil, fuel, and other petroleum-based fluids. - Applications These O-rings are ideal for automotive and industrial applications, like fuel systems, hydraulic systems, and oil seals. 2. Fluoroelastomer (Viton) O-Rings - Characteristics Fluoroelastomers are known for their excellent chemical resistance and high-temperature capabilities. They can withstand extreme conditions without degrading. - Applications Used in aerospace and chemical processing industries, Viton O-rings are often employed in environments with aggressive fluids like acids and solvents.

3. Silicone O-Rings - Characteristics Silicone O-rings are flexible and can endure a wide temperature range. They are not particularly resistant to oils but excel in high-temperature applications. - Applications Commonly found in medical devices, food processing, and HVAC systems, silicone O-rings are suitable for applications that require sterilization or high thermal resistance.

4. Polyurethane O-Rings - Characteristics These O-rings offer exceptional abrasion resistance and good elasticity. They are more durable than traditional rubber O-rings. - Applications Used in applications that require high wear resistance, such as in hydraulic cylinders and aggressive environments.

different types of o rings

5. EPDM O-Rings - Characteristics Ethylene Propylene Diene Monomer (EPDM) O-rings are resistant to weather, ozone, and aging. They are also good at handling high temperatures and steam. - Applications Commonly used in automotive weather seals, roofing applications, and water systems, EPDM O-rings are favored for outdoor and harsh environmental conditions.

Types of O-Rings Based on Design

1. Standard O-Rings - Description These are the most basic O-ring designs, conforming to various industry standards for dimensions and tolerances. - Usage Suitable for general purposes, standard O-rings are available in various materials and sizes.

2. Backup O-Rings - Description A backup O-ring is used in conjunction with a primary O-ring to prevent extrusion under high pressure. - Usage Often seen in hydraulic applications where pressures can exceed the limits of a standard O-ring.

3. D-Rings - Description These have a flattened profile resembling the letter D. - Usage D-rings are often used in dynamic sealing applications where traditional O-rings may not perform as well.

4. Custom O-Rings - Description Sometimes, standard O-rings do not meet specific application requirements. Custom O-rings can be designed and produced to meet these unique needs. - Usage These are widely used in specialized industries where standard solutions are inadequate.

Conclusion

O-rings are essential components in many mechanical systems, providing effective sealing solutions across various industries. By selecting the right type of O-ring based on material and design, businesses can enhance performance, reduce leakage, and extend the lifespan of their products. Understanding the different types of O-rings, including their characteristics and applications, is crucial for anyone involved in manufacturing or maintenance across multiple sectors. Whether you need a standard nitrile O-ring or a specialized Viton seal, the right choice can make all the difference in ensuring operational efficiency and reliability.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories