Exploring Differential Side Seals and Their Impact on Performance and Efficiency

Understanding Differential Side Seals A Comprehensive Overview

Differential side seals are critical components in various mechanical and hydraulic systems, playing a vital role in maintaining performance and reliability. These seals are particularly significant in applications involving gear differentials, commonly found in automotive and industrial machinery. Their primary function is to prevent fluid leakage and ensure that lubricants remain contained within the system, thereby optimizing operational efficiency and prolonging the lifespan of the machinery.

What Are Differential Side Seals?

Differential side seals are designed to fit between the differential housing and the axle shafts in a vehicle’s drivetrain. The differential itself is a mechanical device that allows the outside wheels to rotate faster than the inside wheels during a turn, enhancing vehicle maneuverability and stability. The side seals provide a barrier to prevent oil from leaking out of the differential while simultaneously preventing contaminants such as dirt and debris from entering the system.

Materials and Design

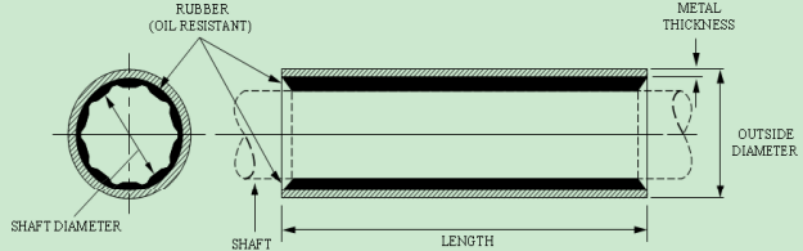

These seals are typically made from durable materials such as rubber, polyurethane, or other synthetic compounds that can withstand harsh operating conditions. The design of differential side seals incorporates features that enable them to cope with high pressures and fluctuating temperatures. The effectiveness of a side seal is influenced by its ability to maintain a consistent and tight fit around the axle shafts, which is why proper installation is crucial.

Importance of Differential Side Seals

1. Fluid Retention One of the primary roles of differential side seals is to retain the lubricating fluid within the differential. This fluid lubricates the gears and bearings, reducing friction and preventing excessive wear. If the seals fail, it can lead to fluid leakage, resulting in inadequate lubrication and potential catastrophic failure of the differential.

2. Contaminant Protection Differential side seals serve as a barrier against external contaminants such as dirt, dust, and water. These contaminants can lead to the premature wear of gears and other internal components, resulting in costly repairs or complete differential replacement.

differential side seal

3. Operational Efficiency Well-functioning seals contribute to the overall efficiency of the vehicle or machinery. By preventing leaks and protecting against contaminants, differential side seals help maintain optimal lubrication pressure, ensuring smooth operation and improved fuel efficiency.

Signs of Seal Failure

Over time, differential side seals can wear out due to prolonged exposure to heat, pressure, and friction. Common signs of seal failure include

- Fluid Leaks The most noticeable indicator is the presence of oil drips beneath the vehicle or machinery. This indicates that the seals may have degraded, allowing fluid to escape. - Unusual Noises Grinding or whining noises from the differential can signal insufficient lubrication due to leaking fluid. - Increased Fluid Levels in Differential If you notice a milky appearance in the differential fluid, it may indicate water contamination, often due to failed seals allowing water intrusion.

Maintenance and Replacement

Regular inspection and maintenance of differential side seals are necessary to ensure their longevity. During routine service checks, mechanics should look for signs of wear or damage. If any issues are identified, timely replacement of the seals is advisable to prevent more significant problems in the future. Depending on the usage and operating conditions, it might also be prudent to replace the seals proactively as part of scheduled maintenance.

Conclusion

In summary, differential side seals are indispensable elements in maintaining the functionality and reliability of differential systems. Understanding their role and significance can help vehicle owners and machinery operators appreciate the importance of regular maintenance and timely replacement. By ensuring these seals are in good condition, operators can enhance the performance and longevity of their equipment, ultimately leading to safer and more efficient operations.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories