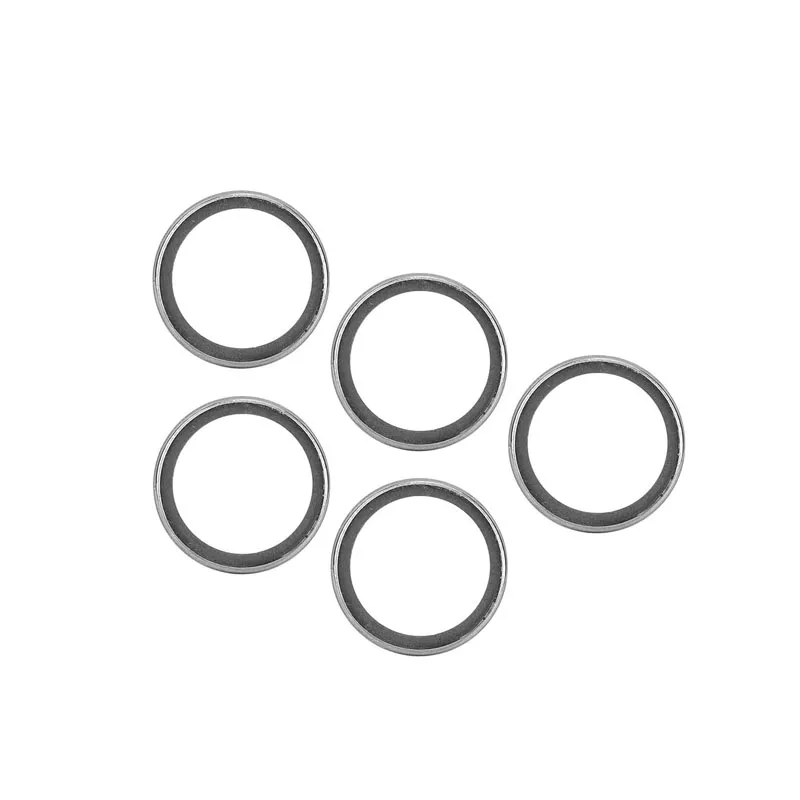

cryogenic o rings

The Importance of Cryogenic O-Rings in Modern Applications

Cryogenic environments, defined as conditions where temperatures drop below -150 degrees Celsius (-238 degrees Fahrenheit), present unique challenges for material science, engineering, and technology. One of the critical components that ensure the functionality and safety of equipment in such extreme conditions is the O-ring. O-rings are essential sealing devices, commonly used in various applications ranging from space exploration to medical equipment. In this article, we will explore the characteristics of cryogenic O-rings, their materials, and their significance in modern industries.

What are Cryogenic O-Rings?

Cryogenic O-rings are circular seals designed to provide a reliable barrier against the escape of fluids or gases in cryogenic settings. These seals are usually made from specific materials that can withstand extremely low temperatures without losing their flexibility or sealing properties. The primary function of an O-ring is to prevent leaks, which could lead to catastrophic failures in systems where precision and reliability are paramount.

Materials and Properties

The materials used for cryogenic O-rings are crucial to their performance. Not all elastomers can withstand cryogenic temperatures; therefore, manufacturers often opt for specialized materials. Common materials include

- Fluorocarbon (Viton) Known for its excellent chemical resistance and ability to maintain sealing capability at low temperatures. - Perfluoroelastomer Offers superior performance in extreme conditions, making it ideal for applications involving aggressive chemicals and cryogenic temperatures. - Silicone and Ethylene Propylene Diene Monomer (EPDM) While not as durable as fluorocarbon options, these materials can still perform adequately in less severe cryogenic environments.

These materials must not only remain flexible at low temperatures but also exhibit low gas permeability to minimize the risk of leaks. Furthermore, the physical properties of these O-rings, such as tensile strength and compression set, are vital to ensure they can cope with the stresses of thermal cycling and pressure changes.

cryogenic o rings

Applications of Cryogenic O-Rings

Cryogenic O-rings find applications across various industries, including

1. Aerospace In space exploration, rockets and satellites operate in a vacuum and often contain liquid fuels and oxidizers at cryogenic temperatures. O-rings are essential components in fuel tanks, valves, and connectors to prevent leaks that could jeopardize missions.

2. Medical Cryogenic technologies are also used in medical applications, such as the preservation of biological samples through cryopreservation. O-rings in cryogenic freezers and storage tanks ensure that the internal environment remains stable and secure.

3. Industrial Gas For the storage and transport of liquefied gases like nitrogen and helium, cryogenic O-rings are vital in maintaining the integrity of storage vessels and pipelines. Any leak in these systems could lead to hazardous situations and significant economic loss.

4. Superconducting Technologies O-rings play a critical role in superconducting magnets used in MRI machines and particle accelerators. These devices require extremely low temperatures to function effectively, making reliable seals essential.

Conclusion

In summary, cryogenic O-rings are indispensable components in various industries that operate under extreme temperature conditions. Their ability to maintain flexibility and sealing capabilities in cryogenic environments is crucial for the safety and efficiency of numerous applications. As technology advances and the demand for cryogenic systems increases, the development and refinement of O-ring materials and designs will continue to play a vital role in ensuring the success of critical operations in aerospace, medical, industrial, and scientific applications. Understanding and improving these seals will lead to enhanced performance, reliability, and safety in all cryogenic applications.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories