Understanding the Role of Cryogenic O-Rings in High-Performance Applications and Their Benefits

The Importance of Cryogenic O-Rings in Modern Applications

Cryogenic O-rings are specialized sealing components designed to function in extremely low temperatures, typically below -150°C (-238°F). These seals are critical in various industries, including aerospace, liquefied gas production, and scientific research, where maintaining the integrity of a system under cryogenic conditions is paramount. In this article, we will explore the significance, materials, and applications of cryogenic O-rings.

Understanding Cryogenic O-Rings

O-rings are circular, elastomeric seals that fit into a groove and are compressed between two surfaces to prevent the leakage of fluids or gases. At cryogenic temperatures, traditional materials often exhibit poor performance due to stiffening or brittleness. Therefore, cryogenic O-rings are manufactured from advanced materials that retain flexibility and strength in extreme conditions.

Material Selection

The performance of cryogenic O-rings largely depends on the material used. Common materials include

1. Fluorocarbon (FKM) Known for excellent chemical resistance and resilience, fluorocarbon O-rings can withstand a wide range of temperatures. However, they generally exhibit limited performance at extremely low temperatures.

2. Perfluoroelastomer (FFKM) These O-rings are engineered for extreme conditions and resist degradation from both chemical exposure and thermal cycling, making them ideal for cryogenic applications. They maintain flexibility down to very low temperatures while providing superior sealing capabilities.

3. Silicone This material is often chosen for its wide temperature range and flexibility. Silicone O-rings can perform adequately at cryogenic temperatures but may not resist certain chemicals as well as fluorinated options.

4. Nitrile (Buna-N) While not typically the best choice for cryogenic applications due to its reduced temperature tolerance, certain formulations can be adapted for specific uses, particularly when cost is a concern.

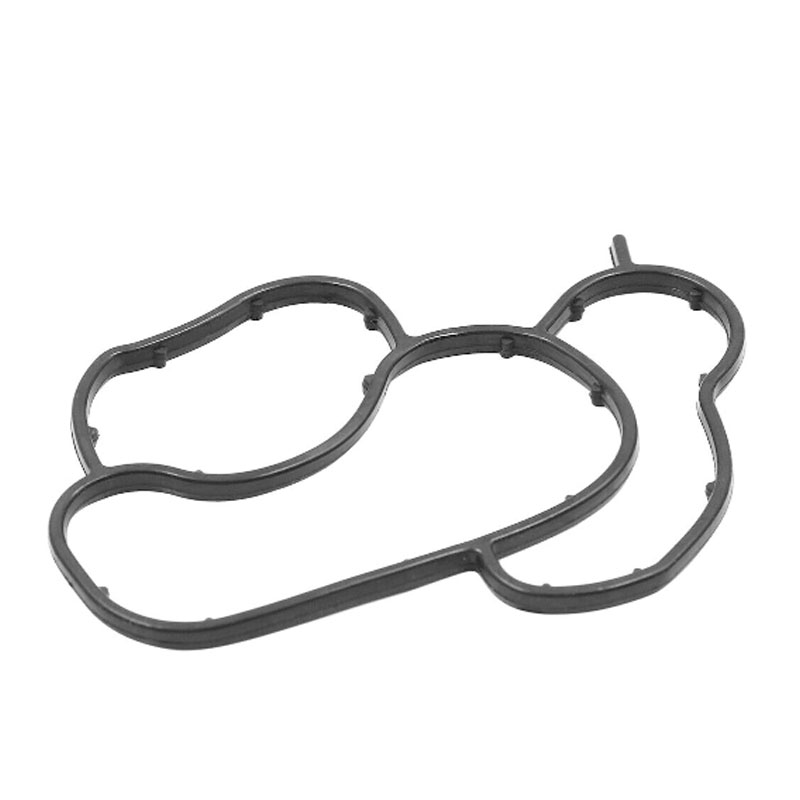

cryogenic o rings

Choosing the right material involves considering the specific application requirements, including temperature extremes, pressures, and exposure to various chemicals.

Applications of Cryogenic O-Rings

Cryogenic O-rings are integral to numerous applications, including

1. Aerospace In the aerospace industry, cryogenic O-rings are utilized in rocket engines and fuel systems that operate with liquid oxygen and hydrogen, which are stored at cryogenic temperatures. A reliable seal is essential to prevent leaks that could lead to dangerous fuel ignitions or loss of propellant.

2. Liquefied Natural Gas (LNG) As the demand for LNG increases, the infrastructure to support its production, storage, and transportation must include effective sealing technologies. Cryogenic O-rings are employed in valves, pumps, and tanks to ensure that liquefied natural gas remains securely contained.

3. Research Facilities Many scientific endeavors, such as those involving superconductors and particle accelerators, require components to function at cryogenic temperatures. Reliable O-rings are critical in maintaining vacuum integrity and preventing contamination.

4. Medical Applications Cryogenic technology is also present in cryotherapy and tissue preservation. O-rings are used in storage tanks for cryoprotectants and other low-temperature applications, ensuring that sensitive materials remain uncontaminated and stable.

Conclusion

Cryogenic O-rings play an essential role in modern technology where extremes of temperature present unique challenges. As industries continue to innovate and expand their use of cryogenic systems, the demand for reliable sealing solutions will only grow. Advancements in materials and manufacturing processes are constant, ensuring that cryogenic O-rings will meet the ever-evolving demands of a variety of sectors. In a world increasingly relying on precision engineering and safety, these small yet mighty components are critical to success.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories