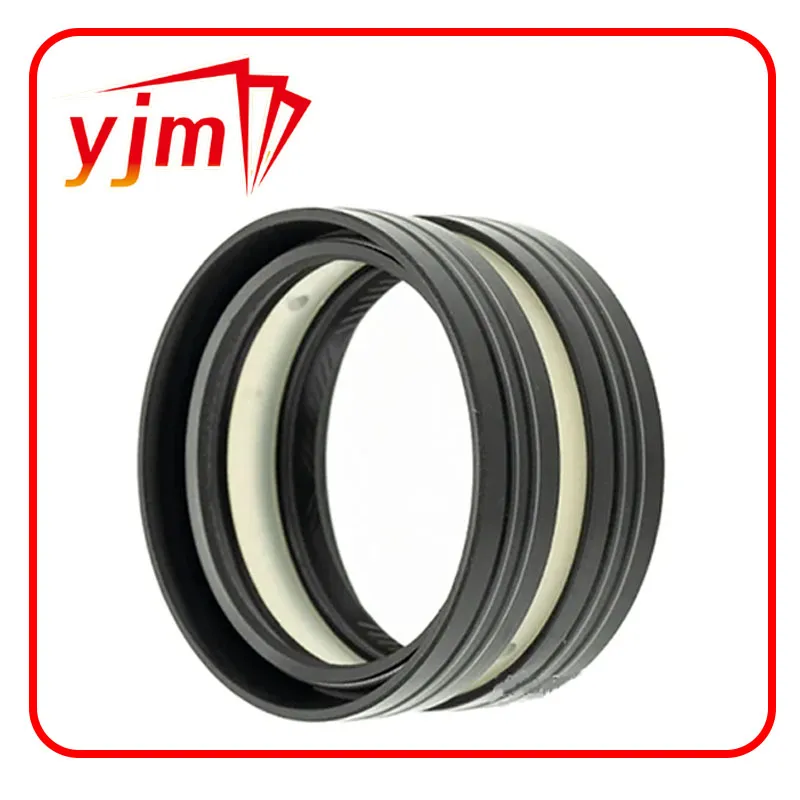

cryogenic o rings

The Importance of Cryogenic O-Rings in Modern Technology

Cryogenic O-rings play a critical role in a myriad of applications across various industries, especially in the aerospace, automotive, and energy sectors. These specialized seals are designed to perform efficiently in extremely low-temperature environments, allowing for reliable operation of various systems that encounter cryogenic fluids like liquid nitrogen, liquid helium, and even liquefied natural gas.

What Are Cryogenic O-Rings?

O-rings are circular gaskets made from elastomeric materials, primarily used to create a seal between two or more components to prevent the leakage of fluids or gases. The term cryogenic refers to substances that have a boiling point lower than −150 degrees Celsius (−238 degrees Fahrenheit). Cryogenic O-rings are specifically engineered to maintain their elasticity and sealing capabilities at these frigid temperatures, which is essential for ensuring the integrity and safety of systems operating in extreme conditions.

Material Composition

The most common materials used for cryogenic O-rings include fluorocarbon (FKM), perfluoroelastomer (FFKM), and silicone-based compounds. These materials offer excellent low-temperature performance while also being resistant to the corrosive effects of various cryogenic fluids. The selection of the appropriate material is crucial, depending on the specific application, as each material has its own unique properties concerning elasticity, compression set resistance, and chemical compatibility.

Applications in Aerospace

cryogenic o rings

In the aerospace industry, cryogenic O-rings are vital for the operation of rocket engines. These engines often utilize cryogenic propellants, such as liquid hydrogen and liquid oxygen, which are stored at extremely low temperatures. O-rings in this context must not only provide a reliable seal but also withstand the mechanical stresses associated with launch conditions. Failure of these seals could lead to catastrophic accidents; therefore, the reliability of cryogenic O-rings is paramount.

Contribution to Energy Sector

In the energy sector, particularly in the field of LNG (liquefied natural gas) transportation and storage, cryogenic O-rings help maintain the integrity of storage tanks and pipelines. As LNG is transported at temperatures around −162 degrees Celsius (−260 degrees Fahrenheit), these seals must perform flawlessly to prevent leaks that could result in financial loss or environmental hazards. The ability of cryogenic O-rings to ensure a tight seal in these conditions is a significant factor in optimizing operation efficiency and safety.

Challenges and Innovations

While the technology surrounding cryogenic O-rings has advanced significantly, challenges remain. One of the primary issues is the physical degradation of the materials over time, especially when exposed to repeated thermal cycling. Innovations in material science and manufacturing processes are continuously being pursued to enhance the durability and performance of these seals. Additionally, the integration of advanced testing and quality assurance processes ensures that only the most reliable O-rings are used in critical applications.

Conclusion

Cryogenic O-rings are indispensable components in a variety of high-tech applications, where reliability and performance are non-negotiable. As industries continue to push the boundaries of technology in extreme conditions, the demand for improved and innovative sealing solutions will only grow. Understanding the significance of these components and investing in their development is crucial for ensuring the safety and success of various high-stakes operations. Whether in aerospace, energy, or other cutting-edge sectors, cryogenic O-rings will continue to play a critical role in modern technological advancements.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories