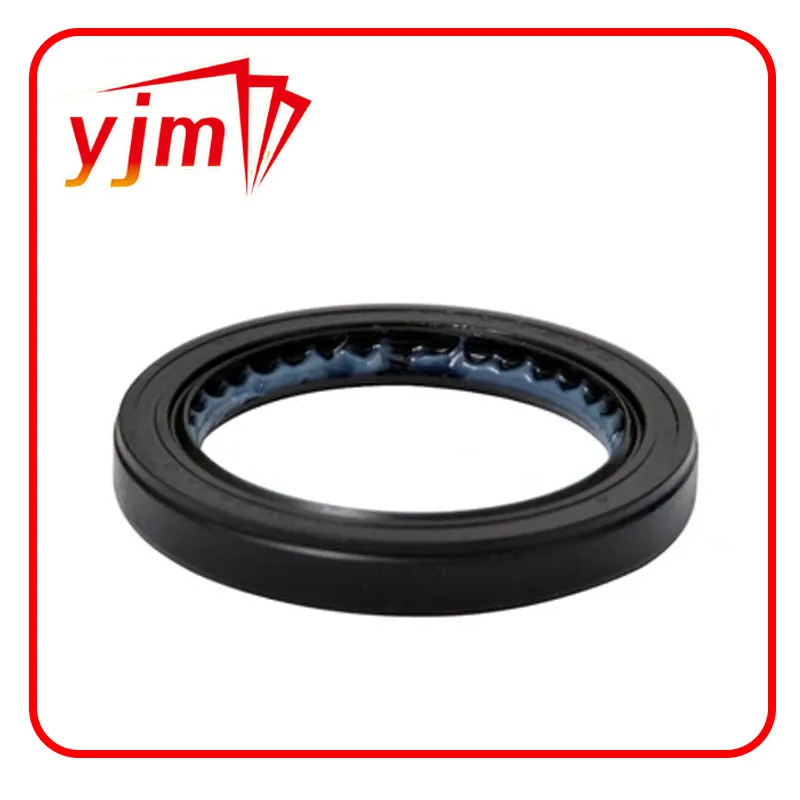

Oil Drain Screw Gasket Oil Crush Washer 12157-10010

Proper maintenance goes beyond just selecting and installing a crush washer. It involves taking an authoritative approach to vehicle care. Documenting your oil changes, noting when and what type of washer was used, and recording the torque applied can provide valuable insights into patterns that may affect your vehicle’s performance or reveal potential issues before they escalate. These records not only enhance your credibility as an informed vehicle owner but also significantly bolster your trust in used vehicle scenarios, as they reflect meticulous attention to detail. Moreover, educating oneself on the evolution and innovations related to sealing technologies can broaden your horizons in automotive maintenance. For example, some manufacturers are experimenting with reusable and revolutionary materials that promise longer lifespans without compromising on efficacy. Staying updated with such innovations ensures that you are always applying the most effective and efficient solutions in your car maintenance regime. In conclusion, the crush washer may appear to be a trivial component in the automotive world, but its importance cannot be overstated. Its role in ensuring a leak-proof oil change process is fundamental to maintaining an engine's health and prolonging its life. By selecting the appropriate washer material, executing proper installation techniques, and maintaining thorough records, you assert your expertise and authority in automotive care. Trust in your vehicle’s reliability is not just a matter of proficient driving skills but also stems from understanding and managing the finer details of car maintenance like the humble crush washer.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories