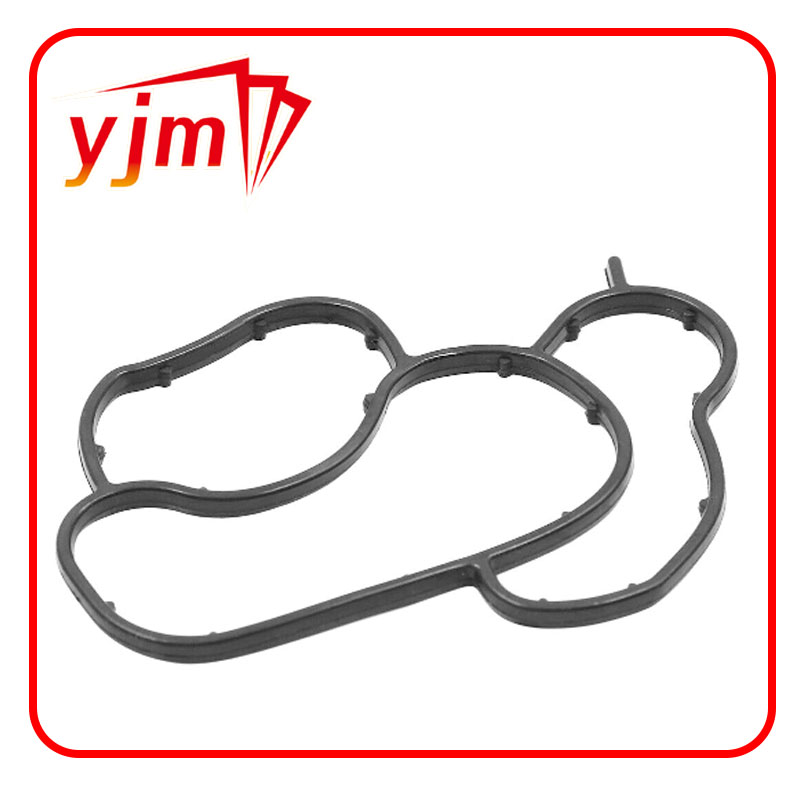

rear crankshaft seal

The economic rationale for investing in high-quality crankshaft rear main oil seals is clear when considering the potential cost of engine repairs due to prolonged oil leakage. A minor investment in superior components and skilled installation can save vehicle owners from the financial burden associated with engine overhauls or the replacement of major engine components. Understanding the influencing factors that can lead to seal failure, such as improper installation, wear and tear due to engine vibration, or exposure to harmful substances, is critical. Moreover, using the correct oil type that matches the engine’s specifications can prolong the life of the rear main seal by reducing unnecessary strain. For automotive enthusiasts and vehicle owners, developing a basic understanding of how crucial crankshaft rear main oil seals are can significantly impact vehicle maintenance strategies. Investing in regular inspections by certified mechanics and choosing high-quality replacement components when necessary ensures that vehicles remain in excellent condition, ultimately reflecting a commitment to vehicle care and maintenance. With automotive technology continuing to evolve, research in seal technology promises further improvements in longevity and reliability. The continued innovation in manufacturing techniques and material science holds the potential to enhance the performance of future crankshaft rear main oil seals, offering solutions that are even more robust and capable of meeting the demands of modern engines. In conclusion, the crankshaft rear main oil seal plays a pivotal role in maintaining engine health, and understanding their function, installation, and maintenance is paramount. As automotive technology progresses, these components will continue to evolve, contributing to more efficient and resilient engine systems. Investing in quality seals and professional maintenance remains a wise choice for vehicle owners aiming for longevity and performance.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories