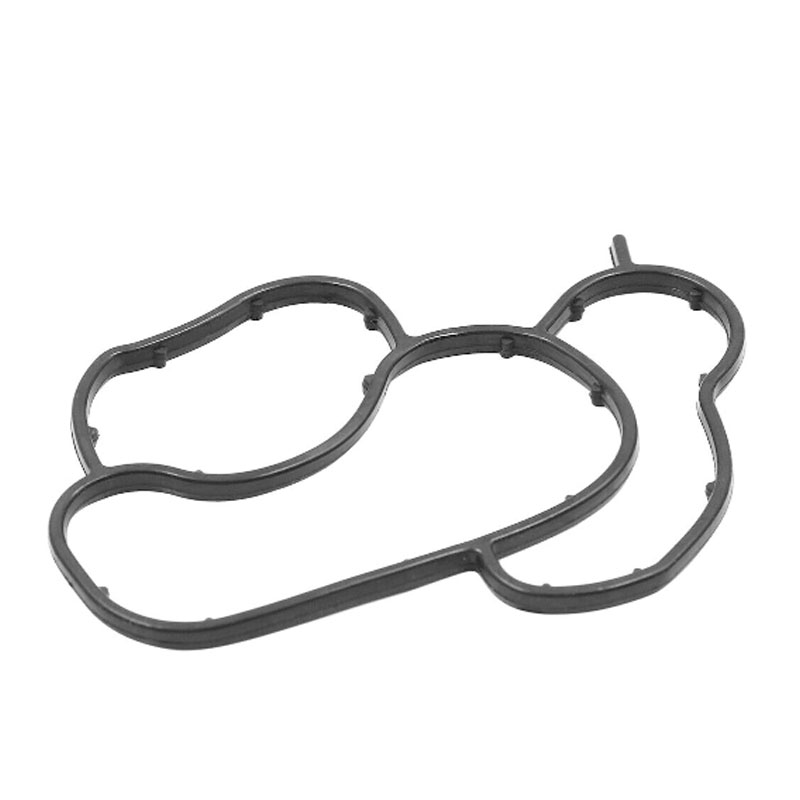

crankshaft main oil seal

Trustworthiness is a cornerstone of any interaction involving crankshaft main oil seals, particularly when it comes to product integrity. Engine builders and repair shops depend on reputable manufacturers whose seals are rigorously tested for quality assurance. Certifications from industry-recognized bodies serve as an added layer of reliability, ensuring that the seals comply with stringent automotive standards. Trust is also built through transparent communication, where manufacturers offer detailed product specifications, installation guidelines, and troubleshooting tips. For automotive experts, understanding the nuances of crankshaft main oil seals extends beyond mere functionality. It's about recognizing how these components interact within the larger system of an engine. For instance, improper installation can lead to misalignment, which exacerbates wear and reduces seal efficiency. Advanced tools, like seal installation guides and torque limiters, are recommended to ensure accuracy and prevent damage during installation. Another aspect worth noting is the importance of proper lubrication. A well-lubricated seal minimizes friction and prevents overheating, thus extending the life of both the seal and the crankshaft. Using the right type of oil and ensuring it remains uncontaminated are simple yet effective ways to ensure the seal performs optimally. Lastly, the future of crankshaft main oil seals is being shaped by advancements in materials science and manufacturing processes. The advent of smart materials and precision engineering is paving the way for seals that can self-adjust to varying conditions, potentially offering unprecedented levels of efficiency and reliability. In conclusion, crankshaft main oil seals are much more than just a small component within an engine. They embody a blend of engineering expertise, authoritative research, and practical experience. Their role in maintaining engine integrity underscores the need for careful selection, regular maintenance, and trust in reputable manufacturers. As technology continues to evolve, so too will the designs and materials of these crucial components, reinforcing their indispensability in the world of automotive engineering.

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

-

The Importance of Heavy Duty Seals in Industrial and Residential Applications

News Jul.30,2025

-

Exploring Industrial Oil Seals: From Felt Oil Seals to TTO and CFW Solutions

News Jul.30,2025

-

Essential Guide to Oil Seals: From Radial to Metal-Cased Seals for Industrial Reliability

News Jul.30,2025

-

Choosing the Right Oil Seals and Gaskets for Industrial and Automotive Applications

News Jul.30,2025

-

Cassette Seals: Durable Sealing Solutions for Harsh Environments

News Jul.30,2025

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

Products categories