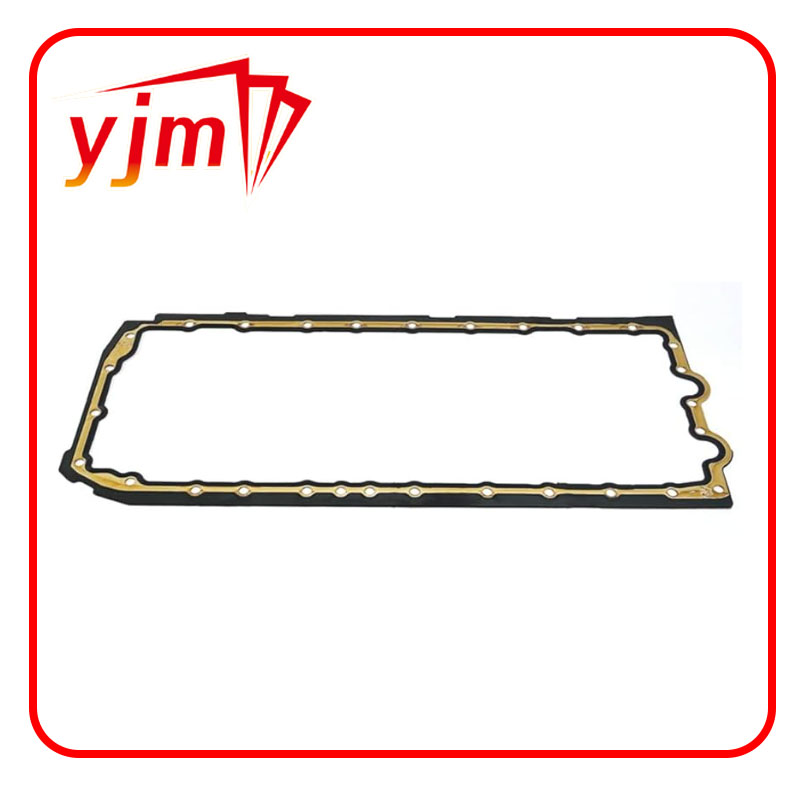

crankshaft gasket seal

Professional installation of a crankshaft gasket seal is another crucial aspect that greatly influences the efficacy of the component. Correct positioning, uniformly-distributed pressure during placement, and ensuring a clean contact surface are essential steps. Mechanics often leverage specialized tools to apply consistent torque, ensuring the gasket seal sits perfectly aligned with the crankcase, thereby optimizing its sealing effectiveness. One cannot overstate the significance of advances in technology that have transformed the design and utility of crankshaft gasket seals. Modern seals are not only superior in durability but are also designed to handle greater variances in temperature and mechanical stress. These innovations allow car manufacturers to produce vehicles that meet stricter emission standards while providing enhanced fuel economy. Furthermore, the selection of the right gasket seal is increasingly nuanced, requiring expertise in interpreting specifications that match it with specific engine requirements. Automobile experts and seasoned enthusiasts advocate for sourcing parts from reputable manufacturers, underlining that the reliability of a gasket seal is reflective of the manufacturer’s commitment to quality and engineering excellence. Finally, as engines transition towards hybrid and fully electric systems, the role of mechanical components such as the crankshaft drastically shifts, yet the principle of high-quality sealing remains critical. While the application may evolve, the foundational knowledge and trust in the performance of gasket seals continue to be imperative. The world of crankshaft gasket seals, much like the engines they serve, is an intricate interplay of science, experience, and innovation. By investing in high-quality materials, ensuring expert installation, and adhering to a routine maintenance schedule, engine operators and manufacturers can achieve a symbiotic relationship between longevity and performance. As technology progresses, so too must our understanding and expertise evolve, ensuring that every tiny component—from the largest to the seemingly minute—contributes to the seamless operation of our vehicles.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories