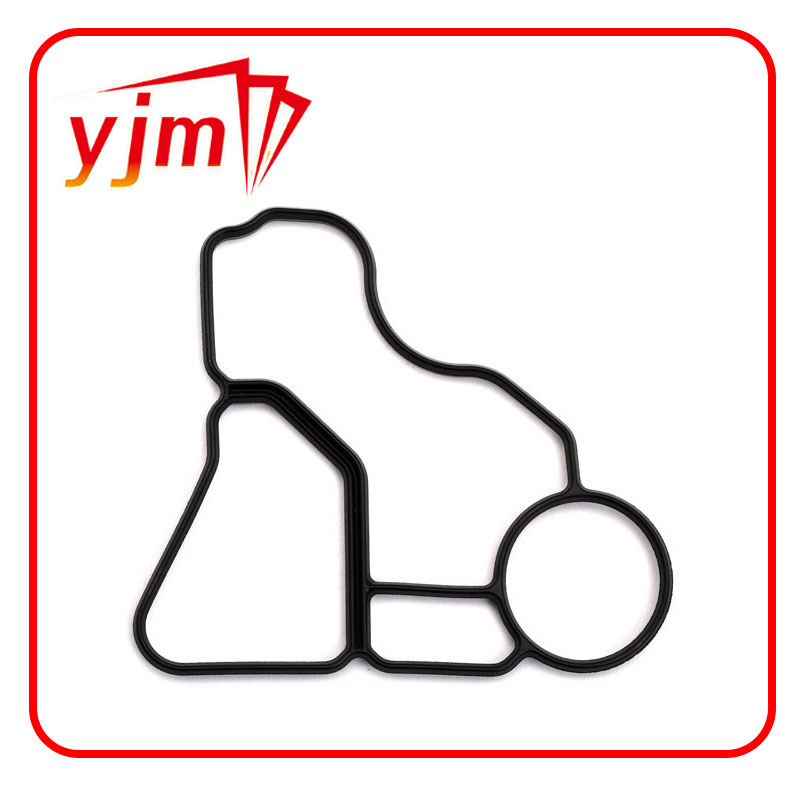

Engine Crankshaft Oil Seal 9031683001

In terms of authoritativeness, consulting historical data and case studies delineates a path for improved designs and function. Engineers pull from a wealth of historical performance data, correlating shaft performance with real-world operational scenarios. This deliberate approach ensures innovations in compressor shaft designs are not just theoretically sound but practically viable. Trustworthiness in compressor shaft manufacturing is ensured by adhering to ISO standards and other relevant industry-specific regulations. These standards lay the groundwork for safety, reliability, and consistency in operations, assuring end-users of the compressor shaft's integrity. Manufacturers often submit shafts to rigorous testing procedures, simulating extreme operational conditions to verify their robustness and reliability. Ultimately, a proficient understanding of compressor shafts is a confluence of material science, mechanical engineering, and practical application insights. By fostering a detailed comprehension of each component and its interaction within a system, businesses can enhance operational efficiency, promote sustainability, and uphold the highest safety standards. To summarize, mastering the subtleties of compressor shafts offers a nexus of opportunities for improving industrial performance. From material selection to engineering precision, adherence to standards, and a focus on sustainability, compressor shafts are an indispensable asset in modern technology applications. Such knowledge not only guarantees performance but also establishes a strong foundation of trust and authority in the field of mechanical machinery.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories