Choosing the Right Flat O-Ring Gasket for Your Sealing Needs

Understanding Flat O-Ring Gaskets Essential Components for Sealing Solutions

Flat O-ring gaskets are vital components in a multitude of industries, serving as effective sealing solutions that prevent the leakage of fluids or gases in various applications. While many might associate O-rings with their typical round shape, flat O-ring gaskets offer unique advantages, especially in scenarios where traditional sealing mechanisms may fall short.

What are Flat O-Ring Gaskets?

Flat O-ring gaskets are typically made from elastomeric materials that provide excellent compressibility and flexibility. Unlike traditional O-rings that are circular in cross-section, flat O-rings have a more elongated shape, which can spread the sealing force over larger areas. This design is particularly beneficial in applications that require a consistent and reliable seal across flanged joints or similar interfaces.

Applications

The applications of flat O-ring gaskets are vast and varied. They are commonly employed in industries such as automotive, aerospace, oil and gas, and water treatment. In automotive applications, for instance, these gaskets are used in engine assembly, oil pans, and transmission cases to ensure a tight seal that prevents leakage of lubricants and other fluids. In aerospace, they play a crucial role in fuel and hydraulic systems, where maintaining pressure is vital for safety and performance.

Moreover, flat O-ring gaskets are instrumental in industries dealing with high-pressure situations, such as oil pipelines or gas transportation. Their ability to maintain integrity under varying temperatures and pressures makes them excellent choices for demanding environments.

Design Considerations

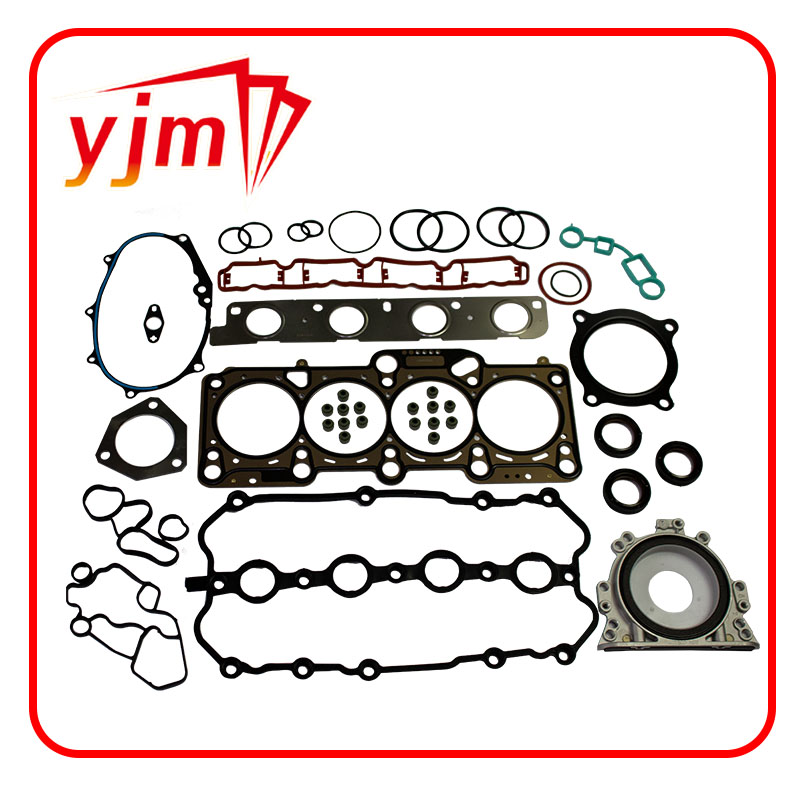

flat o ring gasket

When selecting flat O-ring gaskets, several factors need to be taken into consideration to ensure optimal performance. First and foremost is the choice of material. Common materials include rubber compounds like nitrile, fluorocarbon, and silicone, each with specific properties that may suit particular applications. For instance, nitrile offers good resistance to oils and fuels, while fluorocarbon is effective in high-temperature and chemical environments.

The thickness of the gasket is another critical aspect. A thicker gasket may provide a better seal but could also disrupt alignment in precision applications. Conversely, a thinner gasket might fail to create an adequate seal under pressure. Thus, it’s essential to strike a balance based on the specific requirements of the application.

Additionally, surface finish and flatness of the mating surfaces greatly influence the effectiveness of the gasket. A rough surface finish can lead to uneven sealing, causing potential leaks. Ensuring that surfaces are clean and properly machined will enhance the gasket's performance and longevity.

Advantages of Flat O-Ring Gaskets

The benefits of using flat O-ring gaskets are manifold. Their design allows for easy installation and removal, making maintenance procedures more efficient. They also offer a reliable sealing solution that minimizes the risk of leaks, which is crucial in maintaining operational efficiency and safety.

Another significant advantage is their adaptability. Flat O-ring gaskets can be customized to fit a wide range of sizes and shapes, making them versatile for various applications. Manufacturers can produce gaskets in different thicknesses and materials, ensuring that they meet the diverse needs of their customers.

Conclusion

Flat O-ring gaskets are indispensable for industries that rely on effective sealing solutions to prevent leaks and ensure the proper functioning of machinery and systems. Their unique design and material versatility make them suitable for a variety of applications, from automotive to aerospace and beyond. Understanding the properties and applications of flat O-ring gaskets can lead to more informed decisions when it comes to sealing technology, ultimately enhancing operational efficiency and safety in critical environments. As industries continue to evolve, the demand for reliable sealing solutions like flat O-ring gaskets will undoubtedly grow, cementing their place as essential components in modern engineering.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories