Choosing the Best Heavy Duty Wheel Seals for Enhanced Performance and Durability in Vehicles

Understanding Heavy Duty Wheel Seals Importance and Functionality

Heavy-duty wheel seals are essential components in various heavy machinery and vehicles, including trucks, trailers, and construction equipment. Designed to protect critical drivetrain components from contaminants such as dirt, dust, and water, these seals play a vital role in maintaining the smooth operation and longevity of the machinery they are a part of. In this article, we'll delve into what heavy-duty wheel seals are, how they work, their importance, and some key considerations for choosing the right seal for your application.

What are Heavy Duty Wheel Seals?

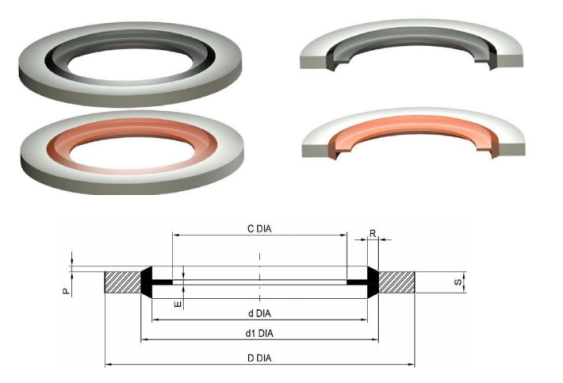

Heavy-duty wheel seals are specialized seals that fit around the wheel hub, providing a barrier against external contaminants while retaining necessary lubrication within the hub itself. Typically made from durable materials such as rubber or composite materials, these seals can withstand harsh working conditions, including extreme temperatures, heavy loads, and chemicals. Their robust design ensures they maintain a tight fit and prevent leaks, which is critical for the efficiency and safety of the equipment.

How Do They Work?

The functionality of heavy-duty wheel seals is relatively straightforward yet highly effective. When a vehicle or piece of machinery operates, the wheel hub rotates, generating friction and potentially allowing foreign particles to enter the assembly. The heavy-duty wheel seal is installed to create a snug fit around the hub, effectively blocking out contaminants.

Moreover, these seals are designed to hold lubricants in place, ensuring that the moving parts within the hub remain adequately lubricated for optimal function. This lubrication is crucial in reducing friction and wear within the wheel bearings, extending their life expectancy and enhancing overall performance.

The Importance of Heavy Duty Wheel Seals

1. Contamination Prevention One of the primary functions of heavy-duty wheel seals is to keep contaminants out. This is crucial in off-road and industrial applications where dust, mud, and water can easily infiltrate wheel assemblies.

2. Extended Equipment Life By preventing contamination and retaining lubrication, these seals help prolong the life of bearings and other hub components. This not only reduces maintenance costs but also minimizes the need for premature replacements.

heavy duty wheel seal

3. Improved Performance A well-sealed wheel hub enhances the overall performance of the vehicle or machinery. It contributes to smoother operation, reducing noise and vibration often caused by wear and tear in unprotected components.

4. Safety Properly functioning wheel seals are critical for safety. Any failure in this area can lead to serious accidents, particularly in heavy machinery where the performance of braking systems and wheel alignment is vital.

Choosing the Right Heavy Duty Wheel Seal

When selecting heavy-duty wheel seals, several factors should be considered

- Material Depending on the working environment and specific requirements (temperature, pressure, exposure to chemicals), the choice of material is crucial. Common materials include nitrile, silicone, and polyurethane, each offering different benefits.

- Size and Fit Ensuring that the seal fits properly is essential. Measurements of the hub and bearing sizes should be taken accurately to avoid leaks and ensure maximum efficiency.

- Seal Type There are various types of seals available, including double-lip seals for extra protection against contaminants. Understanding the specific needs of the application can guide the selection process.

- Brand and Quality Investing in high-quality seals from reputable manufacturers ensures reliability and performance.

In conclusion, heavy-duty wheel seals are fundamental components that support the efficient operation of heavy machinery and vehicles. Their role in preventing contamination, retaining lubrication, and ensuring safety cannot be overstated. By understanding their importance and how they function, operators can make informed decisions that enhance the performance and longevity of their equipment.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories