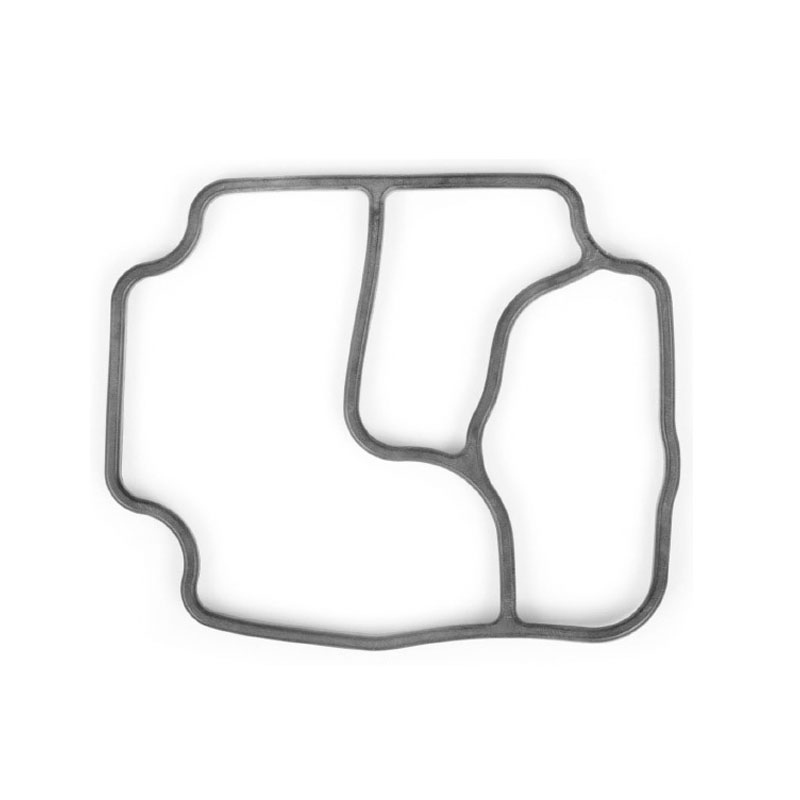

chemical resistant o rings

Understanding Chemical Resistant O-Rings Essential Components for Durability and Reliability

When it comes to engineering and manufacturing, the importance of selecting the right materials cannot be overstated. One often overlooked yet crucial component in a vast array of applications is the O-ring. Specifically, chemical resistant O-rings play a pivotal role in various industries, ensuring the longevity and reliability of seals under harsh conditions. This article delves into the features, benefits, and applications of chemical resistant O-rings.

What Are O-Rings?

O-rings are simple, ring-shaped gaskets made from a variety of materials, serving as seals between two or more parts to prevent leakage of fluids or gases. They are widely used in hydraulic systems, automotive applications, and in the food and beverage industry, among other sectors. Their universal design allows for flexibility, making them adaptable to various shapes and sizes.

Importance of Chemical Resistance

Chemical resistance is a significant criterion when selecting O-rings, especially in applications involving aggressive fluids or corrosive environments. O-rings that lack chemical compatibility can lead to seal degradation, which in turn results in leakage, equipment failure, or even catastrophic accidents in extreme cases. Thus, choosing a chemical resistant O-ring is essential for maintaining system integrity and safety.

Materials for Chemical Resistant O-Rings

O-rings can be made from several different materials, each tailored to withstand specific chemicals and environmental conditions. Here are some of the most common materials used in manufacturing chemical resistant O-rings

1. Fluoroelastomer (Viton) Known for its excellent resistance to a wide range of chemicals, Viton O-rings are particularly effective against oils, fuels, and solvents. They can withstand high temperatures, making them ideal for automotive and aerospace applications.

2. Nitrile Rubber (NBR) Nitrile O-rings are versatile and exhibit good resistance to petroleum-based products. However, they are less effective against polar solvents and high-temperature environments.

3. PTFE (Teflon) PTFE O-rings are engineered for use in situations with strong chemicals and extreme temperatures. They are resistant to almost all chemicals but may lack flexibility in lower temperatures.

4. Ethylene Propylene Diene Monomer (EPDM) These O-rings are excellent for applications involving water, steam, and a variety of chemicals. They maintain their properties over a wide temperature range and are known for their longevity.

5. Silicone While silicone O-rings offer good thermal stability, they are not suitable for all chemicals. They are primarily used in applications requiring flexibility and resilience over a broader temperature range.

chemical resistant o rings

Advantages of Using Chemical Resistant O-Rings

2. Leak Prevention Properly selected and installed chemical resistant O-rings minimize the risk of leaks, ensuring that systems operate efficiently and safely.

3. Versatility With a variety of materials available, chemical resistant O-rings can be tailored to meet the specific requirements of diverse applications, from food processing to oil and gas.

4. Safety Compliance In many industries, especially those dealing with hazardous materials, using the right chemical resistant O-rings ensures compliance with safety regulations and standards.

Applications of Chemical Resistant O-Rings

Chemical resistant O-rings find utility in numerous applications across various industries. Some common applications include

- Automotive Used in fuel systems and hydraulic components to prevent leaks. - Aerospace Essential for fuel, hydraulic, and pneumatic systems exposed to extreme temperatures and pressures.

- Manufacturing Vital in machinery that processes corrosive chemicals or requires sealing under high pressures.

- Pharmaceuticals Used in equipment where contamination must be avoided, ensuring safe and sterile operations.

- Food Industry Ensures compliance with health standards, preventing contamination in food processing and packaging.

Conclusion

In a world where precision and reliability are paramount, chemical resistant O-rings are essential components that can help prevent costly downtime and hazardous situations. By carefully selecting the appropriate material, engineers and manufacturers can ensure their systems operate smoothly and safely. Whether in automotive, aerospace, or any industrial application, the right chemical resistant O-ring is a small but critical investment in your project’s success.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories