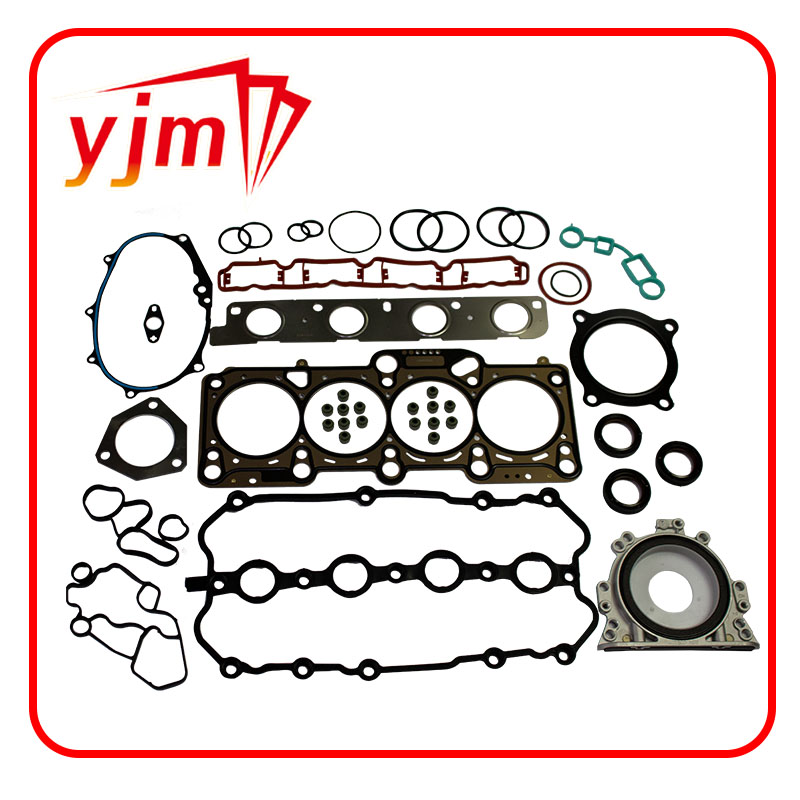

cassette seals manufacturer

The Importance of High-Quality Cassette Seals Insights from Manufacturers

In the world of manufacturing, the importance of reliable sealing solutions cannot be overstated. Among these, cassette seals have emerged as crucial components in various industries, ensuring efficiency and longevity of machinery and equipment. As manufacturers of cassette seals, we understand the intricacies of designing these components to meet a multitude of operational demands.

The Importance of High-Quality Cassette Seals Insights from Manufacturers

One of the defining features of modern cassette seals is their adaptability. Manufacturers are increasingly developing customizable solutions to cater to specific customer requirements. This can include modifying dimensions, materials, and sealing technologies to fit unique operational contexts. This flexibility is vital in industries like oil and gas, chemical processing, and pharmaceuticals, where equipment specifications can vary widely.

cassette seals manufacturer

Quality control is another paramount concern for cassette seals manufacturers. Rigorous testing and inspection processes are essential before these components reach the market. Techniques such as dynamic testing, pressure testing, and environmental simulations are employed to ensure that the seals can perform reliably under expected conditions. By maintaining high standards of quality, manufacturers can significantly reduce the risk of equipment failure, which not only affects productivity but also poses safety hazards.

Furthermore, innovation in sealing technology plays a pivotal role in the development of cassette seals. With advancements in materials science and engineering, manufacturers are continuously exploring new ways to enhance the performance of seals. This includes the incorporation of smart materials that can adapt to changing operational conditions, as well as improved design techniques that minimize wear and extend the lifespan of seals.

The global market for cassette seals is highly competitive, and manufacturers must stay ahead by focusing on research and development. By engaging with customers and understanding their challenges, manufacturers can create targeted solutions that meet specific needs. Additionally, collaboration with industry partners can lead to shared knowledge that drives innovation and enhances product offerings.

In conclusion, the role of cassette seals in various industries is indispensable, underlining the significance of selecting a reliable manufacturer. High-quality cassette seals not only ensure operational efficiency but also contribute to the overall safety and reliability of equipment. As manufacturers continue to innovate and uphold strict quality standards, the future of cassette seals looks promising, paving the way for enhanced performance in various applications.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories