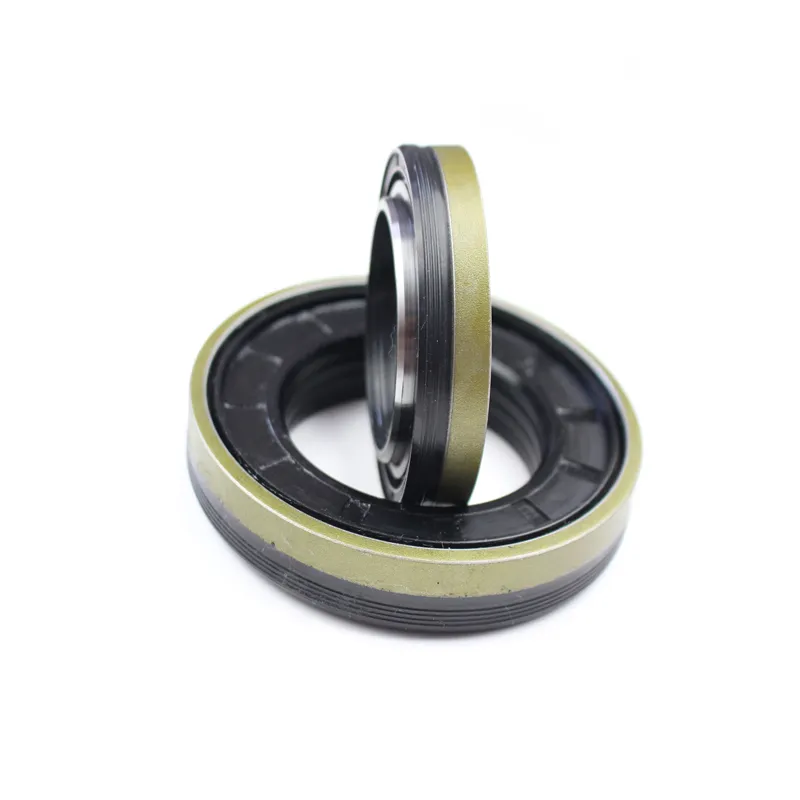

car o ring

The Importance of the Car O-ring A Small Component with a Big Impact

In the intricate world of automotive engineering, even the smallest components can play a crucial role in the performance and reliability of a vehicle. Among these components, the O-ring is a particularly noteworthy example. Often overlooked, the O-ring is essential for ensuring that cars operate smoothly, efficiently, and safely. This article delves into the significance of the car O-ring, exploring its functions, types, applications, and maintenance.

What is an O-ring?

An O-ring is a circular sealing component made from elastomeric materials such as rubber or silicone. Its design is simple a continuous loop that, when compressed between two surfaces, creates a seal that prevents the leakage of fluids or gases. The O-ring can be found in various sizes, materials, and hardness levels, making it versatile enough to be used in numerous applications in automotive design.

Functions of O-rings in Vehicles

In the automotive arena, O-rings are employed in a wide array of applications. They serve several vital functions, such as

1. Sealing Fluids O-rings prevent the leakage of engine oil, coolant, and other fluids. This function is critical for maintaining optimal fluid levels within the engine and other systems, which is essential for vehicle performance.

2. Preventing Air Leaks O-rings are used in air intake and exhaust systems to ensure that air flows efficiently without any leaks. This not only improves engine performance but also reduces emissions.

3. Vibration Damping O-rings can act as vibration dampers, helping reduce noise and prolonging the life of components by absorbing shocks and vibrations.

4. Pressure Regulation In high-pressure applications, such as hydraulic systems in power steering and brake systems, O-rings provide a reliable seal that can withstand significant pressure variations without failure.

Types of O-rings

car o ring

O-rings come in various types, each suited for specific applications. Common types include

1. Nitrile O-rings These are the most widely used O-rings in automotive applications. Nitrile rubber is resistant to petroleum-based oils and fuels, making it ideal for sealing engine components.

2. Fluorocarbon O-rings Known for their excellent resistance to high temperatures and various chemicals, fluorocarbon O-rings are often used in high-performance and luxury vehicles.

3. Silicone O-rings While not typically used in high-pressure applications, silicone O-rings are excellent for withstand extreme temperatures. They are often found in sealing applications where temperature variations are significant.

4. EPDM O-rings Ethylene Propylene Diene Monomer (EPDM) O-rings resist environmental factors such as UV exposure, ozone, and weathering, making them ideal for external applications.

The Impact of O-ring Failure

When O-rings fail, the consequences can be severe. A leaking O-ring can lead to engine oil degradation, coolant loss, or hydraulic system failure. Each of these issues can compromise vehicle performance and safety. For instance, a malfunction in the braking system due to an O-ring failure can have life-threatening implications. Regular inspections and maintenance can help prevent such failures, ensuring that O-rings remain in optimal condition.

Maintenance and Replacement

Maintaining O-rings involves regular inspections, particularly during oil changes and routine maintenance checks. Mechanics will often check for signs of wear, such as cracks or brittleness, and replace any O-rings that show damage. Using the correct type of O-ring for specific applications is equally vital; using the wrong material can lead to premature failure.

Conclusion

The car O-ring may be a small, humble component, but its significance in automotive engineering cannot be overstated. From maintaining fluid levels to preventing air leaks, these circular seals perform critical functions that are fundamental to vehicle operation. Understanding the roles, types, and maintenance of O-rings can help vehicle owners appreciate this often-overlooked component while ensuring their cars run smoothly and efficiently. Just as each part of a vehicle works together to create a cohesive machine, the O-ring plays its part in the larger framework of automotive design, demonstrating that sometimes, the smallest elements are indeed the most important.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories