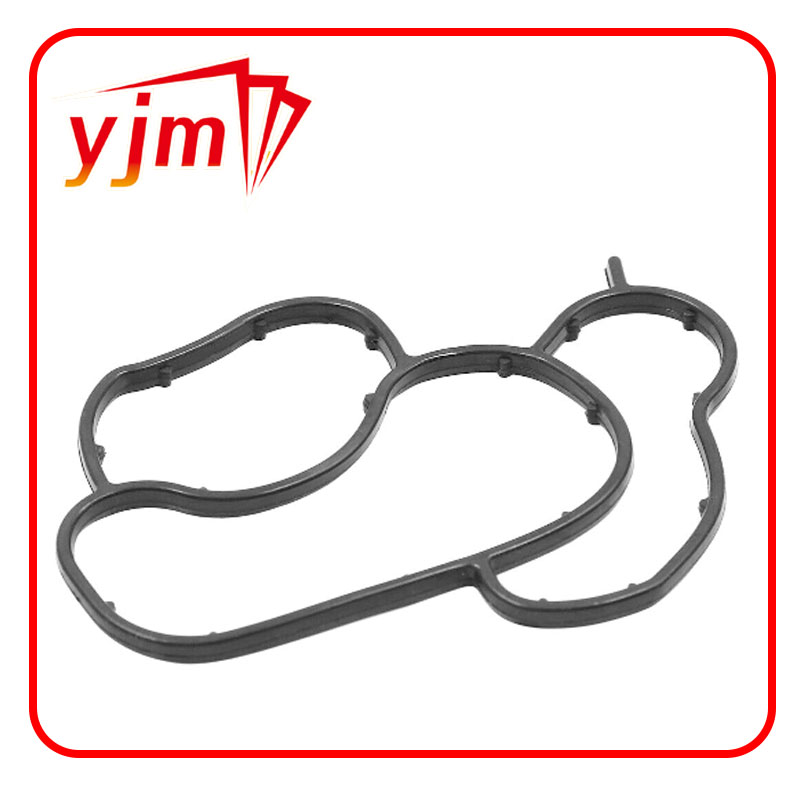

Seal Ring 006 997 71 47

Furthermore, environmental factors can influence the longevity and efficacy of car air conditioning O-rings. Frequent exposure to extreme temperatures can cause these components to wear faster. Drivers in particularly hot or cold climates should be mindful of scheduling regular inspections to look for cracks or imperfections in O-rings. The topic of car air conditioning O-rings might not dominate automotive forums or SEO trends, but its importance cannot be overstated. Drivers often overlook the role these components play, assuming that modern air conditioning systems are self-sustaining. This misconception can lead to user frustrations when faced with air conditioning failures. As experts in the automotive field emphasize, those small, inexpensive O-rings can become the weakest link in the cooling chain if neglected. Lastly, consumer education and awareness about aftermarket verses OEM (original equipment manufacturer) O-rings can make a discernable difference. While aftermarket options are tempting due to their lower prices, they may not meet the same quality standards as OEM parts. Compromising on this quality can result in diminished system performance and life span. Investing in OEM parts ensures that the O-rings fit perfectly with the specifications designed by the manufacturer and sustain the car's seamless operation for years to come. In conclusion, while car air conditioning O-rings may be a small part of a vehicle’s complex ecosystem, their role in maintaining optimal air conditioning performance is undeniably pivotal. By choosing the right materials, focusing on proper installation, and keeping an eye on wear and tear, drivers can ensure their vehicle’s cooling system remains efficient and effective over its lifetime. Prioritizing these considerations not only fosters a pleasant driving experience but also underscores a broader commitment to vehicle maintenance and personal comfort on the road.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories