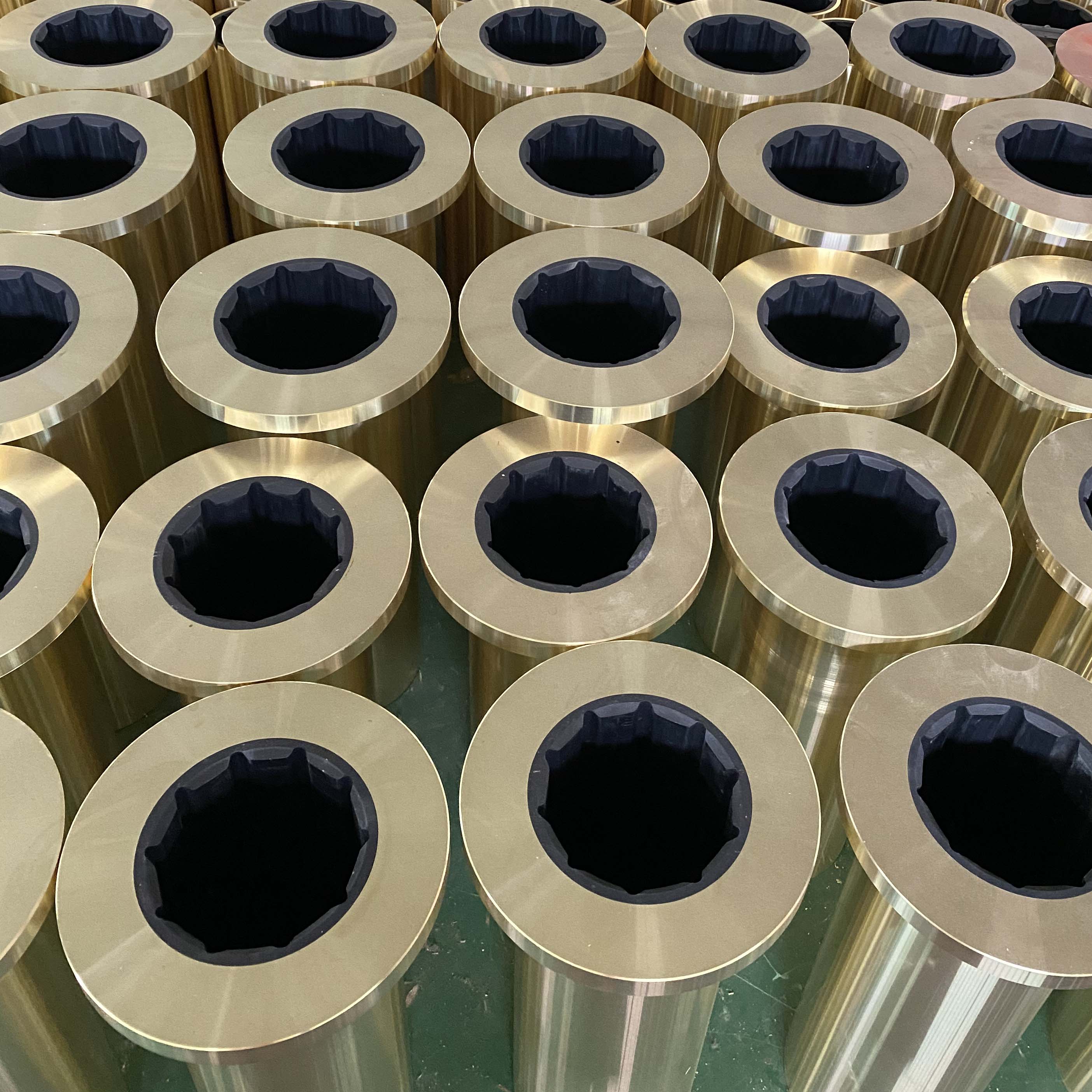

bspp bonded seal

The BSPP Bonded Seal A Comprehensive Overview

In the world of mechanical engineering and fluid technologies, sealing components play a critical role in ensuring the efficiency and safety of machinery. Among the various sealing solutions available, the BSPP (British Standard Pipe Parallel) bonded seal stands out as a popular and effective choice. This article explores the design, functionality, and applications of the BSPP bonded seal.

Understanding BSPP Bonded Seals

A BSPP bonded seal, also known as a bonded washer or sealing ring, consists of a metal washer and a rubber or elastomeric sealing element bonded together. The design essentially combines the rigidity of metal with the flexibility of rubber, providing an effective sealing solution that can withstand a variety of environmental conditions.

The traditional BSPP thread design features parallel threads that do not form a taper, which means that the seals must rely on an O-ring or bonded seal to create a tight seal. The bonded seal seats against the face of the connection, providing a leak-proof barrier that is critical for applications involving fluids or gases.

Key Features of BSPP Bonded Seals

1. Material Composition The core of a BSPP bonded seal is typically made of durable metals such as stainless steel or brass, while the bonded sealing element is made from high-quality elastomers, such as Nitrile rubber (NBR), Fluoroelastomers (FKM), or EPDM. This combination allows the seal to resist wear, temperature fluctuations, and chemical exposure.

2. Pressure Resistance BSPP bonded seals are designed to withstand high-pressure environments, making them suitable for applications in hydraulic and pneumatic systems. They maintain their sealing integrity under varying pressure conditions, which is critical for safety and reliability.

3. Temperature Tolerance The elastomeric materials used in the seal construction offer excellent temperature resistance, allowing them to function effectively in both high and low-temperature environments. This makes them suitable for applications in the automotive, aerospace, and manufacturing sectors.

4. Ease of Installation One of the significant advantages of BSPP bonded seals is their ease of installation. They can be installed without the need for special tools, and their construction allows for a straightforward fitting process, reducing downtime in industrial settings.

Applications of BSPP Bonded Seals

bspp bonded seal

BSPP bonded seals find applications across various industries, thanks to their versatility and effective sealing capabilities

- Automotive Industry In vehicles, BSPP bonded seals are used in oil and fuel lines, as well as in other engine components where secure sealing is crucial to prevent leaks and enhance efficiency.

- Hydraulics and Pneumatics These seals are widely used in hydraulic systems where high pressures can lead to leaks if not properly sealed. They provide a reliable barrier in hydraulic lines, cylinders, and valves.

- Oil and Gas In the oil and gas industry, BSPP bonded seals are employed in drilling equipment and pipelines, where they prevent corrosive fluids from escaping, thereby increasing safety and environmental protection.

- Aerospace The aerospace industry requires components that can withstand extreme conditions. BSPP bonded seals serve crucial functions in aircraft systems, ensuring leak-proof operations in pressurized environments.

Advantages Over Traditional Seals

What sets BSPP bonded seals apart from traditional sealing methods, such as O-rings or flat washers, is their enhanced sealing performance. The combination of metal and rubber ensures better adaptability to varying surface conditions and compensates for minor misalignments during installation. This adaptability leads to greater long-term reliability and reduced maintenance needs.

Additionally, the bonded design offers excellent resistance to aging and deformation, which is a common issue with single-component seals. This longevity contributes to the overall performance and lifespan of the machinery they are used in.

Conclusion

BSPP bonded seals are a robust sealing solution that combines the best properties of metal and elastomeric materials. Their versatility and reliability make them indispensable in various industries where leaks can lead to significant operational challenges. Companies looking to improve their sealing solutions should consider the advantages of BSPP bonded seals, not just for their performance but also for the overall efficiency and safety they bring to their applications. As technology continues to evolve, the role of effective sealing solutions like BSPP bonded seals will undoubtedly increase, contributing to more sustainable and efficient industrial practices.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories