Understanding BSPP Bonded Seal Applications and Benefits in Sealing Solutions

The Significance of BSPP Bonded Seals in Industrial Applications

In the realm of industrial sealing solutions, the BSPP (British Standard Parallel Pipe) bonded seal has emerged as a critical element for ensuring leak-proof connections in various applications. As industries continue to evolve and expand, the demand for effective sealing methods has become increasingly important, making the understanding of BSPP bonded seals essential.

What is a BSPP Bonded Seal?

A BSPP bonded seal typically consists of a metal washer and an elastomeric (rubber) sealing element. The design of this seal allows it to accommodate both the mechanical and thermal stresses that arise during operation. The metal washer ensures structural integrity while the rubber acts as a flexible barrier that prevents the escape of fluids or gases, making it an ideal choice for applications where high pressure and temperature variations are prevalent.

Key Features and Benefits

1. Versatility BSPP bonded seals are versatile, ideal for a multitude of applications, including hydraulic systems, automotive transmissions, and gas pipelines. Their ability to provide effective sealing in both dynamic and static operating conditions makes them a preferred choice across various sectors.

2. Enhanced Durability The combination of metal and rubber enhances the durability of these seals. The metal provides strength and rigidity, while the rubber offers flexibility and resilience. This combination is effective in withstanding vibrations, thermal expansion, and contraction, thus extending the seal’s lifespan.

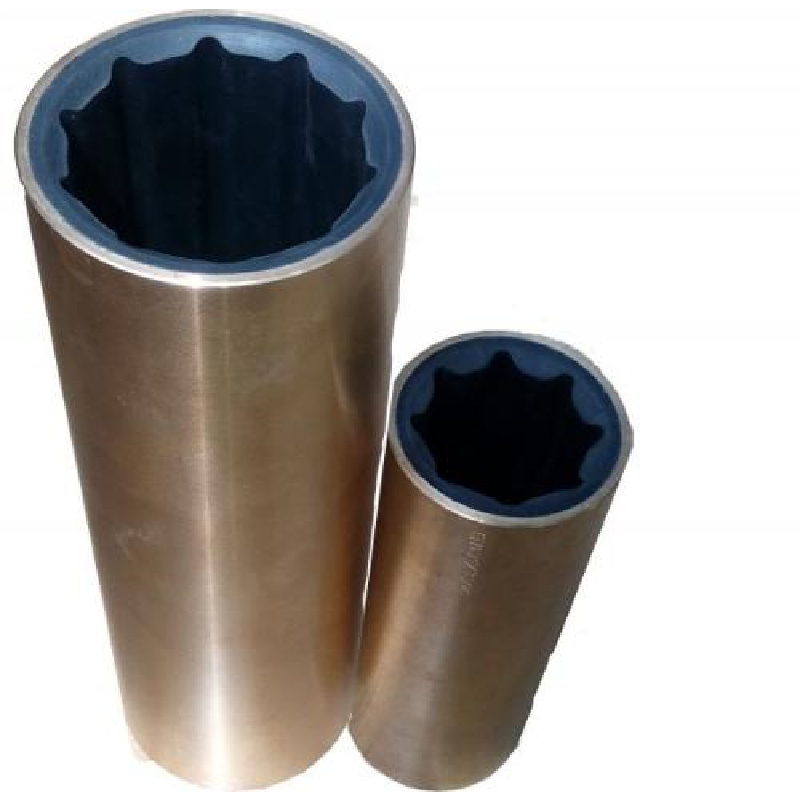

bspp bonded seal

3. Leak Prevention One of the most significant advantages of BSPP bonded seals is their effectiveness in preventing leaks. With the rise in environmental concerns and regulations, the need for sealing solutions that can effectively contain hazardous substances has never been more pressing. BSPP bonded seals play a vital role in minimizing the risk of leaks, thereby protecting both the environment and equipment.

4. Ease of Installation The design of BSPP bonded seals allows for straightforward installation. The seals can be easily fitted into existing connectors without the need for specialized tools, which saves time and reduces labor costs during assembly.

5. Cost-Effectiveness While the initial investment in high-quality BSPP bonded seals may be slightly higher than traditional sealing methods, their durability and reliable performance lead to lower maintenance costs over time. This cost-effectiveness makes them a sound investment for businesses aiming to optimize their operations.

Applications of BSPP Bonded Seals

BSPP bonded seals find applications in a wide array of industries. They are extensively used in the automotive sector for engine components, transmission systems, and fuel systems. In hydraulics, these seals are critical in hydraulic pumps and cylinders where pressure control is essential. The oil and gas industry also benefits from BSPP bonded seals in drilling operations, pipelines, and refining processes, where effective sealing is necessary to prevent leaks of dangerous substances.

Conclusion

In conclusion, BSPP bonded seals are indispensable components in modern industrial applications. Their ability to provide effective sealing solutions while adapting to various conditions makes them a go-to choice for engineers and manufacturers alike. As industries continue to face increased pressure for efficiency and safety, the importance of reliable sealing methods cannot be overstated. By choosing BSPP bonded seals, companies can ensure the integrity of their systems, protect the environment, and contribute to sustainable industrial practices. Implementing these seals not only enhances operational efficiency but also sets a foundation for long-term reliability and safety in various industrial environments.

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

-

The Importance of Heavy Duty Seals in Industrial and Residential Applications

News Jul.30,2025

-

Exploring Industrial Oil Seals: From Felt Oil Seals to TTO and CFW Solutions

News Jul.30,2025

-

Essential Guide to Oil Seals: From Radial to Metal-Cased Seals for Industrial Reliability

News Jul.30,2025

-

Choosing the Right Oil Seals and Gaskets for Industrial and Automotive Applications

News Jul.30,2025

-

Cassette Seals: Durable Sealing Solutions for Harsh Environments

News Jul.30,2025

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

Products categories