BSP Bonded Seals for Enhanced Leak Prevention and Durability in Mechanical Applications

Understanding BSP Bonded Seals A Comprehensive Overview

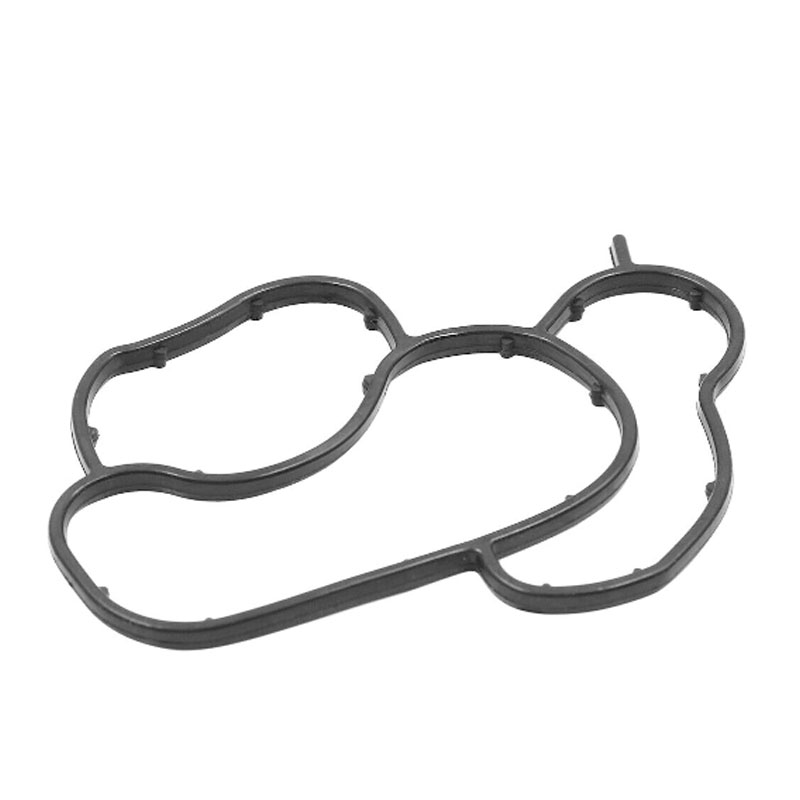

BSP bonded seals, commonly referred to as bonded washers or bonded seals, are essential components used in various engineering applications to ensure reliable sealing in mechanical systems. They are particularly important in situations where there is a need to prevent the leakage of fluids or gases under high pressure and temperature conditions. These seals combine the best attributes of rubber and metal, which makes them an ideal choice for numerous applications across different industries.

A BSP bonded seal consists of a rubber sealing element bonded to a metal ring, typically made of stainless steel or another corrosion-resistant material. The rubber portion plays a crucial role in creating a tight seal when compressed against the surfaces it is fitting. The metal component provides structural support and enhances the durability of the seal, ensuring that it can withstand various operational stresses.

Understanding BSP Bonded Seals A Comprehensive Overview

In automotive applications, for example, bonded seals are often used in oil pans, fuel systems, and various engine parts. Their ability to prevent oil leaks and maintain pressure is crucial to the efficiency and longevity of engine components. Similarly, in hydraulic systems, they play a vital role in ensuring the integrity of fluid connections, where even a minor leak could lead to system failure and significant safety hazards.

bsp bonded seal

Moreover, the installation of BSP bonded seals is relatively straightforward. They can be placed easily into the corresponding recesses of flanges or joints, and once tightened, they conform perfectly to the surfaces, creating a reliable seal. This ease of installation not only saves time but also reduces the risk of errors during assembly, thereby enhancing overall system performance.

Another important aspect of BSP bonded seals is their versatility. They are available in various sizes, thicknesses, and rubber compounds, which allows engineers to select the most appropriate seal for specific applications. For instance, seals made from silicone rubber can withstand higher temperatures, making them ideal for exhaust systems, while nitrile rubber seals are often preferred in fuel applications due to their excellent compatibility with hydrocarbons.

Maintenance of BSP bonded seals is typically minimal, but regular inspections are advised to ensure that they are not worn or damaged. Signs of wear may include cracking or distortion, and it is essential to replace seals showing these signs to maintain system integrity.

In conclusion, BSP bonded seals are vital components that play a crucial role in ensuring the reliability and efficiency of various mechanical systems. Their unique design, which combines rubber and metal, offers excellent sealing capabilities under challenging conditions. As industries continue to innovate and push the boundaries of engineering, the demand for effective sealing solutions like BSP bonded seals will undoubtedly remain strong. When selecting sealing components, consideration of their specific properties and applications will lead to enhanced system performance and reduced operational risks.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories