Brass Cutlass Bearing for Optimal Marine Performance and Durability in Boat Propulsion Systems

The Brass Cutlass Bearing An Overview of Its Importance and Applications

The brass cutlass bearing is a critical component in various marine and industrial applications, especially where rotating shafts need support. Made typically from a non-metallic composite or solid brass material, this type of bearing is designed to reduce friction and wear between moving parts. It serves a vital role in ensuring smooth operation, thereby extending the lifespan of machinery and enhancing overall performance.

Historical Context

The cutlass bearing has a rich history that dates back to the early days of naval engineering. Originally, ships relied on wooden or iron bearings, which often suffered from corrosion, excessive wear, and frequent maintenance requirements. The introduction of brass into bearing design was a significant technological advancement. Brass, an alloy of copper and zinc, provides several desirable properties, including corrosion resistance, antimicrobial qualities, and excellent machinability. These attributes make brass cutlass bearings particularly well-suited for the harsh maritime environment.

Design and Functionality

A typical brass cutlass bearing is cylindrical in shape, allowing it to fit snugly around a shaft. Its design may incorporate a series of grooves or flutes to facilitate the flow of lubricants, which is essential for reducing friction. This bearing type is primarily used to support stern tubes, which connect the ship's propulsion systems to the hull, and provide a stable yet pliable interface for rotating shafts.

One of the essential features of brass cutlass bearings is their ability to operate efficiently in water

. The natural lubrication provided by seawater helps minimize wear, while the brass material ensures resistance to the damaging effects of saltwater corrosion. Additionally, these bearings can handle varying temperatures, making them suitable for use in diverse environments.Applications

Brass cutlass bearings play a crucial role in a variety of applications beyond marine contexts. In the world of industrial machinery, they are employed in pumps, compressors, and conveyor systems. Their resistance to wear and environmental factors makes them ideal for use in manufacturing settings where reliability is paramount.

brass cutlass bearing

In marine applications, cutlass bearings are predominantly found in recreational boats as well as larger vessels, including cargo and fishing ships. The performance of these bearings directly impacts the efficiency of the propulsion systems, thereby influencing fuel consumption and overall operational costs. As vessels continue to evolve, the demand for reliable and efficient bearing systems such as the brass cutlass bearing remains strong.

Maintenance Considerations

Maintaining brass cutlass bearings is relatively straightforward, yet it plays a vital role in their longevity. Regular inspections are necessary to detect signs of wear, corrosion, or unusual vibration patterns that could indicate a failing bearing. Proper lubrication is essential, as it ensures the bearing can operate efficiently without excessive wear. In many cases, a simple freshwater rinse followed by the application of appropriate marine grease can significantly extend the bearing's life.

Advantages and Challenges

The advantages of brass cutlass bearings are numerous. They are relatively low-cost, durable, and require minimal maintenance compared to other bearing types. Furthermore, their ease of installation and the availability of various sizes make them a versatile choice for many applications.

However, brass cutlass bearings also have their challenges. For example, while they are highly durable, they can be susceptible to wear over time, especially in high-stress applications. Additionally, the continuous exposure to harsh environmental conditions calls for regular upkeep to prevent degradation.

Conclusion

In conclusion, the brass cutlass bearing represents a significant innovation in the world of rotating machinery, offering a blend of performance, durability, and ease of maintenance. Its applications span across marine and industrial sectors, making it a truly versatile component. As technology advances and demands for better efficiency and performance increase, the continual refinement of cutlass bearing designs, including new materials and innovations, will ensure their relevance for years to come. Understanding their importance can help engineers and mechanics better appreciate the role they play in various systems, further driving the evolution of machinery design.

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

-

The Importance of Heavy Duty Seals in Industrial and Residential Applications

News Jul.30,2025

-

Exploring Industrial Oil Seals: From Felt Oil Seals to TTO and CFW Solutions

News Jul.30,2025

-

Essential Guide to Oil Seals: From Radial to Metal-Cased Seals for Industrial Reliability

News Jul.30,2025

-

Choosing the Right Oil Seals and Gaskets for Industrial and Automotive Applications

News Jul.30,2025

-

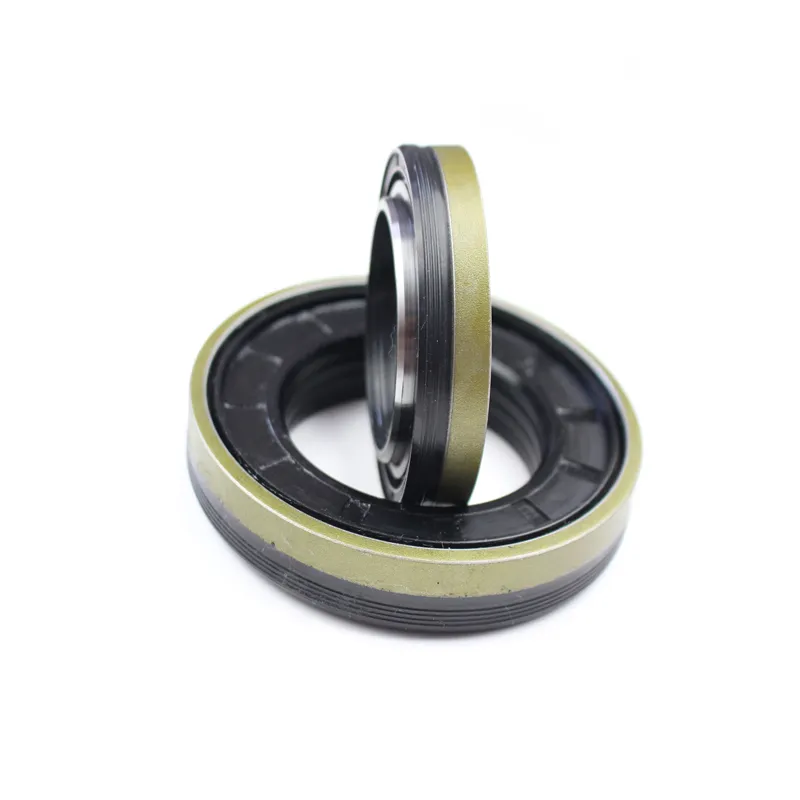

Cassette Seals: Durable Sealing Solutions for Harsh Environments

News Jul.30,2025

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

Products categories