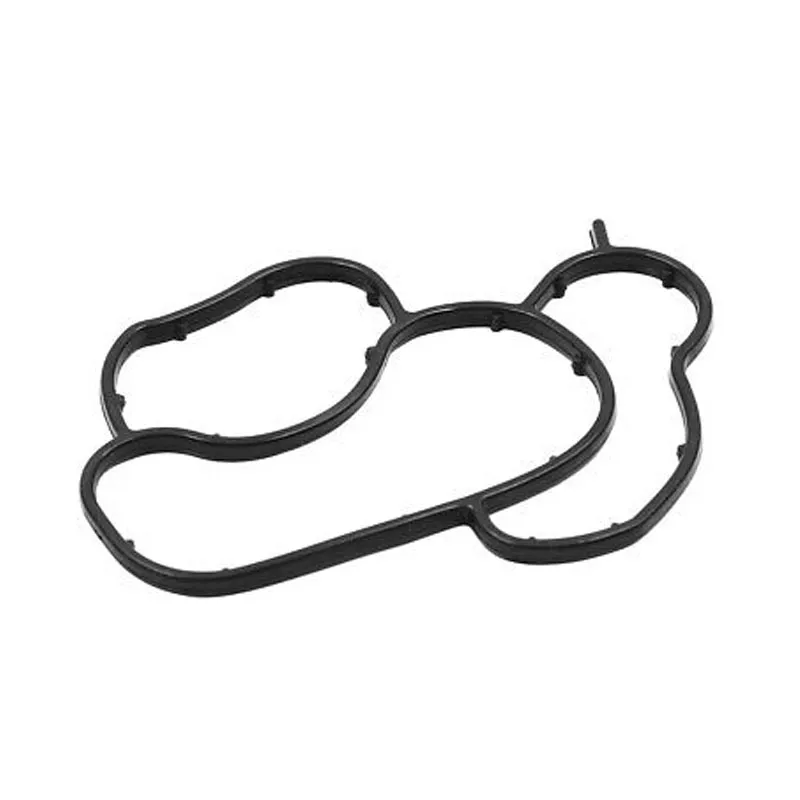

Seal Ring 006 997 71 47

Trustworthiness in the field of O-rings isn't just about selecting the right material but also ensuring traceability and adherence to manufacturing standards. Reputable suppliers provide certificates of compliance, detailing the composition and testing credentials of their O-rings. This documentation is critical for maintaining transparency and ensuring that components meet the specified requirements. One of the challenges frequently encountered in the market is the presence of counterfeit or substandard O-rings that fail to meet the rigorous demands of brake fluid resistance. These inferior products often lead to premature failure, posing safety risks. From a trustworthy provider, you can expect comprehensive support, from material selection to offering insights on installation and maintenance that can prevent common issues such as O-ring nicking or improper seating, both of which can compromise sealing integrity. The implementation of brake fluid resistant O-rings is a testament to the advances in materials science and engineering. According to specialists in automotive design, future developments in O-ring technology will likely focus on enhancing durability further and introducing new materials that can withstand even harsher conditions while remaining cost-effective. Such innovations promise improved performance, contributing to the safety and reliability of automotive systems globally. In conclusion, for any enterprise focusing on automotive production and maintenance, investing in high-quality brake fluid resistant O-rings is a strategic choice. Their contribution to vehicle safety and efficiency underscores their importance in the broader context of automotive engineering. As a dedicated professional in this domain, sharing insights and practical advice on selecting and deploying these components effectively not only fortifies industry practices but also elevates the standard of safety for all users.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories