High-Performance O-Rings for Enhanced Brake Fluid Resistance and Durability

Understanding Brake Fluid Resistant O-Rings Essential Components for Safe Vehicle Operation

In the world of automotive engineering, the importance of reliable components cannot be overstated. Among these crucial elements are O-rings, specifically designed to withstand the demanding conditions presented by brake fluid. Brake fluid resistant O-rings are integral in ensuring the efficiency and safety of braking systems, and understanding their properties and applications can help both manufacturers and consumers make informed choices.

What are O-Rings?

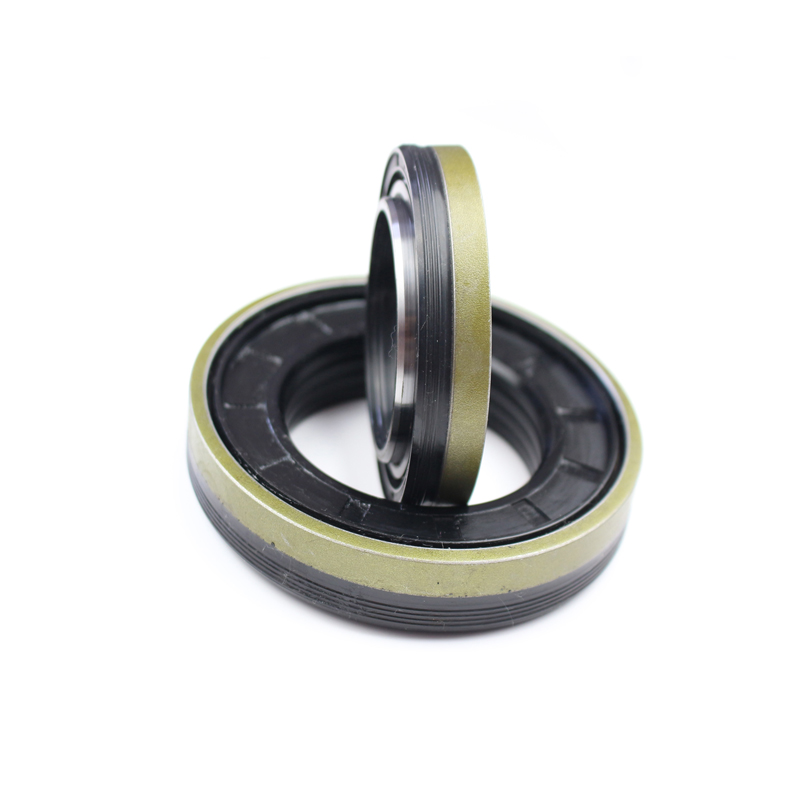

O-rings are circular sealing elements that play a vital role in preventing fluid leaks in a variety of applications. They are typically made from elastomeric materials, which provide the necessary flexibility and durability to maintain a secure seal. When compressed between two mating surfaces, O-rings create a barrier that prevents the escape of fluids and gases. Their simple design and cost-effectiveness make them a popular choice in many industries, including automotive, aerospace, and manufacturing.

The Role of Brake Fluid Resistant O-Rings

In a vehicle, the braking system is one of the most critical safety features. Brake fluid, which is essential for proper brake function, can be corrosive and damaging to standard O-rings. Therefore, engineers and manufacturers utilize brake fluid resistant O-rings made from specialized materials, such as Viton (FKM), Nitrile (NBR), or other high-performance elastomers.

These materials are specifically engineered to withstand the harsh chemical properties of brake fluid. They offer superior resistance to heat, pressure, and chemical degradation, ensuring that the O-rings maintain their sealing capabilities over time. A breakdown of the seal can lead to brake fluid leakage, reduced braking performance, and ultimately pose a serious safety risk to vehicle occupants.

brake fluid resistant o rings

Benefits of Using Brake Fluid Resistant O-Rings

1. Enhanced Safety The primary benefit of using brake fluid resistant O-rings is the enhancement of vehicle safety. A reliable seal ensures that the braking system operates effectively, allowing drivers to maintain control of their vehicles under various driving conditions.

2. Extended Service Life High-quality O-rings that can withstand brake fluid exposure are less likely to degrade or fail, resulting in a longer service life for both the O-rings and the components they protect. This longevity translates into fewer maintenance issues and a reduction in the frequency of part replacements.

3. Cost-Effectiveness While brake fluid resistant O-rings may have a higher initial cost compared to standard O-rings, their durability and reliability can lead to overall cost savings. Fewer repairs or part replacements can offset the initial investment, making them an economical choice in the long run.

4. Versatility Brake fluid resistant O-rings are not limited to automobiles; they are also used in motorcycles, trucks, and various hydraulic systems. Their versatility makes them suitable for a wide range of applications where fluid integrity is crucial.

Conclusion

In conclusion, brake fluid resistant O-rings are a small yet indispensable component in the vehicle braking system. Their ability to withstand the corrosive nature of brake fluid while providing a reliable seal is crucial for ensuring the safety and performance of any vehicle. Choosing the right material for O-rings can make a significant difference in longevity and functionality. As technology continues to evolve, the materials and designs of these O-rings will likely advance, further enhancing their performance and reliability. As consumers and manufacturers alike understand their importance, the push towards safer and more efficient vehicles will be strengthened, paving the way for a better driving experience.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories