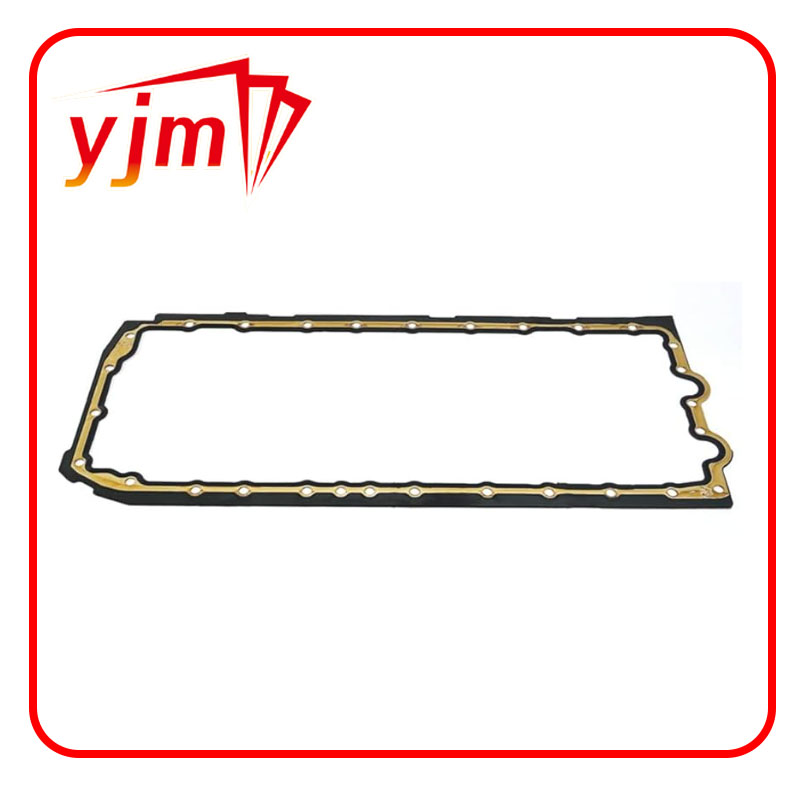

bonded seal ring

Understanding Bonded Seal Rings Applications and Advantages

Bonded seal rings, often referred to simply as bonded seals, are vital components in various engineering applications and industries. These seals are designed to provide reliable sealing performance, preventing the leakage of fluids and gases, which is crucial in maintaining the integrity of mechanical systems. In this article, we will delve into what bonded seal rings are, their construction, applications, and the benefits they offer.

What are Bonded Seal Rings?

Bonded seal rings consist of a metal washer with an elastomeric sealing element bonded to its inner circumference. The typical construction involves rubber materials such as Nitrile, EPDM, or Viton, which are engineered to provide excellent sealing properties under varying conditions of temperature, pressure, and chemical exposure. The metal component, typically made of steel or aluminum, provides structural support and enhances durability.

The tailor-made design of bonded seal rings allows them to be effective in a variety of applications, especially where a reliable seal is needed without the complexity of additional sealing methods.

Applications of Bonded Seal Rings

Bonded seal rings are commonly found in numerous industries, including

1. Automotive Industry In vehicles, bonded seals are used in engines, transmissions, and hydraulic systems. They help to prevent leaks in oil passages and fluid reservoirs, contributing to the overall performance and longevity of the vehicle.

2. Aerospace In the aerospace sector, reliability and safety are paramount. Bonded seals are utilized in fueling systems, hydraulic circuits, and pneumatic systems, where they ensure that fluids are contained effectively under high-stress conditions.

3. Oil and Gas In oil drilling and transportation, maintaining a secure seal is critical due to the volatile nature of the materials handled. Bonded seals are employed in various applications from drilling equipment to pipeline connections, safeguarding against leaks that could lead to catastrophic failures.

4. Machinery and Heavy Equipment In construction and agricultural machinery, bonded seal rings are critical in hydraulic systems and engine components. Their durability ensures that these machines can operate efficiently under demanding conditions.

bonded seal ring

5. HVAC Systems In heating, ventilation, and air conditioning systems, bonded seals help prevent air and fluid leaks, improving system efficiency and reliability.

Advantages of Bonded Seal Rings

The popularity of bonded seal rings in various applications can be attributed to several significant advantages

1. Reliable Sealing Performance Bonded seals provide a robust seal that remains effective under varying temperatures and pressures. The combination of metal and elastomeric materials allows for greater flexibility in design and functionality.

2. Resistance to Chemicals Depending on the materials used, bonded seal rings can be formulated to resist a wide range of chemicals, making them suitable for aggressive environments found in industries such as oil and gas or chemical processing.

3. Ease of Installation Bonded seal rings are straightforward to install, requiring minimal tools and expertise. Their design ensures they can be fitted quickly, reducing downtime during maintenance or assembly.

4. Durability and Longevity The use of high-quality materials in bonded seal rings translates to extended service life, even under the most demanding conditions. This reduces the frequency of replacements and maintenance, leading to cost savings over time.

5. Versatility Bonded seal rings are suitable for an extensive range of applications thanks to their customizable nature. Different sizes, materials, and designs can be created to meet specific requirements.

Conclusion

In summary, bonded seal rings are essential components across various industries where fluid and gas sealing is critical for operational safety and efficiency. Their unique design combines the structural integrity of metal with the flexibility and sealing ability of elastomers, providing a reliable solution for many applications. As industries continue to advance, the demand for innovative and effective sealing technologies like bonded seal rings will undoubtedly grow, underscoring their importance in modern engineering. With their myriad of benefits, it is clear that bonded seal rings are more than just simple seals; they are a fundamental part of maintaining efficiency and safety in various mechanical systems.

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

Products categories