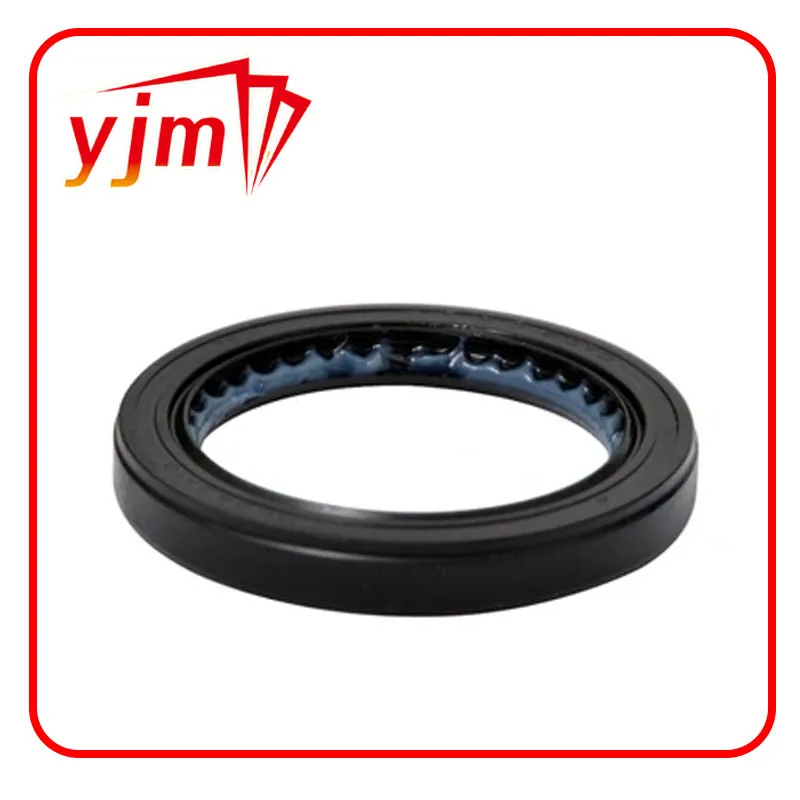

bonded seal 1 4

Trustworthiness is another cornerstone of bonded seals, particularly for the 1/4 size used in precision machinery. Manufacturers and suppliers of these seals are typically ISO certified, which assures that the production processes meet international standards for quality and safety. Product testing, another crucial aspect, involves measures like tensile strength evaluations, pressure resistance tests, and long-term durability assessments. Users who prioritize quality will find that top-tier manufacturers provide comprehensive test data to back their claims, thereby enhancing the credibility of their products. In terms of application, the 1/4 size bonded seal is highly versatile yet specialized. It is suitable for sealing in conditions where the bolt size or the component bore is precisely 1/4 inch, a common size in compact and medium-sized mechanical assemblies. This specificity ensures that the seal fits perfectly, minimizing the risk of misalignment, which can lead to leakage. For industries where even the slightest leak can result in considerable downtime and expense, the precision of the bonded seal is invaluable. Knowing how to install these seals correctly is another aspect where experience and expertise play a role. Even the highest quality seals can fail if not installed properly. Installation involves proper alignment and ensuring that the seal is not subjected to twisting or shearing forces that could compromise its integrity. Experts recommend using tools designed for precision assembly to avoid damaging the rubber element during installation. In conclusion, the bonded seal size 1/4 embodies a blend of precision, reliability, and versatility, making it a trusted choice for industry professionals worldwide. Through years of field use and rigorous testing, these seals have proven their worth by providing consistent, secure seals that meet the demands of various applications. Their development speaks to a deep understanding of sealing technology, reflecting authoritative industry knowledge and commitment to quality. As such, the bonded seal remains a critical component in the toolkits of engineers and technicians, ensuring the efficient, safe, and reliable operation of machinery in a broad spectrum of industries.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories