bonded seal 1 2

Understanding Bonded Seals An In-Depth Look at Bonded Seal 1 2

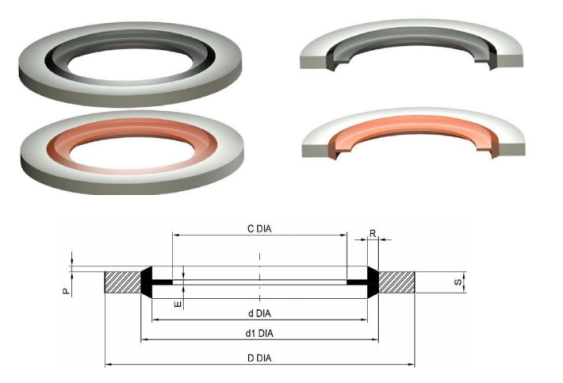

Bonded seals, also known as bonded washers or bonded gaskets, are essential components in various industries, particularly in automotive, aerospace, and manufacturing. These seals are designed to provide a reliable and effective barrier against leaks in fluid systems. A popular type of bonded seal is the Bonded Seal 1 2, which combines a rubber sealing element with a metal outer ring to enhance performance and durability. In this article, we will explore the features, benefits, and applications of Bonded Seal 1 2.

Features of Bonded Seal 1 2

The Bonded Seal 1 2 is engineered to meet the demands of high-pressure and high-temperature environments. The construction consists of a rubber material, often made of nitrile or silicone, bonded to a metal ring, usually crafted from zinc-plated steel or stainless steel. This dual material design allows it to withstand various environmental conditions while maintaining an effective seal.

One of the key features of the Bonded Seal 1 2 is its unique profile. The inner rubber element provides excellent flexibility and compressibility, ensuring a perfect fit against the mating surfaces. Meanwhile, the rigid outer metal ring provides structural support and prevents the seal from extruding under pressure. This combination results in a reliable seal that can handle fluctuating pressures and temperatures without compromising performance.

Benefits of Using Bonded Seal 1 2

The Bonded Seal 1 2 offers numerous advantages over traditional sealing solutions. First and foremost, its design minimizes the risk of leaks, which is crucial in applications where fluid containment is vital. This quality not only protects the environment but also enhances the safety and efficiency of the machinery involved.

bonded seal 1 2

Additionally, the bonded design simplifies installation. Unlike conventional seals that may require precise placement, the Bonded Seal 1 2 can be easily positioned and aligned due to its integral design. This ease of installation can significantly reduce labor costs and installation time, making it an attractive choice for manufacturers and technicians alike.

Another notable benefit is its versatility. The Bonded Seal 1 2 is suitable for various applications, including hydraulic systems, oil systems, and even applications involving aggressive chemicals. Its ability to function effectively in diverse environments makes it a preferred choice across multiple industries.

Applications of Bonded Seal 1 2

The applications of Bonded Seal 1 2 are extensive. In the automotive industry, it is commonly used in engine components, transmission systems, and cooling systems to prevent fluid leaks and ensure optimal performance. In the aerospace sector, these seals can be found in fuel systems, where failure could lead to catastrophic results.

Moreover, in manufacturing equipment, Bonded Seal 1 2 is often utilized in pumps and compressors, where durability and reliability are paramount. Its proven performance in these demanding environments underscores its value as a sealing solution.

Conclusion

In summary, the Bonded Seal 1 2 is a remarkable sealing solution that combines the flexibility of rubber with the rigidity of metal to provide a robust and reliable seal. Its unique features, numerous benefits, and wide range of applications make it an indispensable component in various industries. As technology continues to advance, the importance of effective sealing solutions like Bonded Seal 1 2 will undoubtedly continue to grow.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories