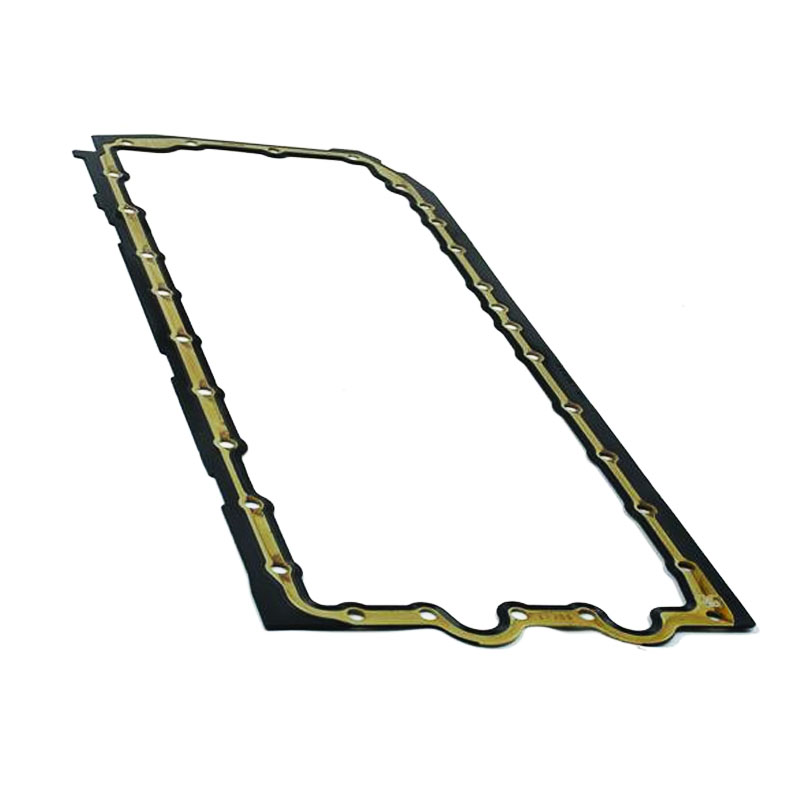

bolt drain plug

Understanding the Bolt Drain Plug A Vital Component in Fluid Management

In many mechanical and automotive applications, effective fluid management is crucial for optimal performance and longevity. Among the various components designed for this purpose, the bolt drain plug stands out as an essential element. This article delves into the significance, design, installation, and maintenance of bolt drain plugs, highlighting their role in ensuring efficient fluid management in engines, machinery, and other systems.

What is a Bolt Drain Plug?

A bolt drain plug is a type of fastener that serves the primary function of sealing a drain hole, typically found in fluid reservoirs such as engine oil pans, transmission housings, and hydraulic systems. When closed, it prevents fluid from leaking out while allowing for easy draining when necessary. These plugs are often made from materials such as steel, aluminum, or plastic, depending on the application and the chemical properties of the fluids involved.

Importance of Bolt Drain Plugs

1. Fluid Containment The primary purpose of a bolt drain plug is to contain fluids within a system. Whether it’s engine oil, coolant, or hydraulic fluid, maintaining the integrity of the system is essential for proper operation. A leak can lead to severe mechanical failures and costly repairs.

2. Ease of Maintenance Bolt drain plugs facilitate routine maintenance by enabling quick and effortless fluid changes. Without these plugs, draining fluids would be a messy and time-consuming process, complicating maintenance schedules.

3. Environmental Protection Properly sealed drain plugs minimize the risk of spills and leaks, contributing to environmental protection. In industries where hazardous fluids are prevalent, the importance of effective sealing cannot be overstated, as leaks can lead to serious environmental hazards.

4. Cost Efficiency Regular maintenance enabled by efficiently functioning drain plugs can ultimately save money. By routinely changing fluids and preventing contamination, users can extend the life of their machinery and reduce repair costs.

bolt drain plug

Design and Features

Bolt drain plugs come in various sizes and designs to fit different applications. They typically feature a tapered or threaded design that allows for a tight seal when inserted into a drain hole. In some cases, these plugs may also have additional features such as built-in washers or O-rings to enhance sealing capabilities and prevent leaks.

The choice of material for a bolt drain plug can significantly impact its performance. Steel plugs are durable and resistant to wear, making them suitable for high-pressure applications. On the other hand, aluminum plugs are lightweight and more resistant to corrosion, ideal for automotive use. Plastic plugs, while not as robust, offer excellent chemical resistance for specific applications.

Installation and Maintenance

Installing a bolt drain plug is typically a straightforward process. It involves cleanly threading the plug into the drain hole and tightening it adequately to ensure a secure seal. However, it is crucial to avoid over-tightening, which can lead to stripping the threads or damaging the plug.

Regular checks on bolt drain plugs should be part of any maintenance routine. Users should inspect for signs of wear, corrosion, or leakage. If any issues are identified, it’s essential to replace the plug promptly to avoid potential system failures. Additionally, using thread sealants can provide an added layer of security against leaks.

Conclusion

The bolt drain plug may seem like a small component in the overarching scheme of mechanical systems, but its role is vital. As a key element in fluid management, it ensures containment, facilitates maintenance, protects the environment, and helps users save on long-term costs. By understanding its importance, design, and the best practices for installation and maintenance, individuals and industries can ensure the efficient operation of their machinery and avoid unnecessary complications.

In summary, whether in automotive, industrial, or any applications involving fluid systems, the bolt drain plug is an indispensable component that deserves recognition and proper care. Recognizing the value of such components is crucial for any technician, engineer, or DIY enthusiast looking to maintain efficiency and reliability in their systems.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories