best gasket material for oil pan

The Best Gasket Material for Oil Pans

When it comes to maintaining the integrity of an engine, the oil pan gasket plays a crucial role. Responsible for sealing the oil pan to the engine block and preventing leaks, choosing the right gasket material is essential for ensuring optimal engine performance. In this article, we will explore the best gasket materials for oil pans, their properties, advantages, and how to select the most suitable one for your vehicle.

Understanding Oil Pan Gaskets

Before diving into the materials, it's important to understand the function of oil pan gaskets. These gaskets create a tight seal between the oil pan and the engine block, preventing oil leaks that can lead to serious engine damage. Given the harsh conditions they endure — including exposure to high temperatures, pressure changes, and oil chemical properties — the materials used for these gaskets must exhibit durability, flexibility, and resilience.

Common Gasket Materials

1. Rubber Gaskets Rubber is one of the most common materials used for oil pan gaskets. It offers excellent flexibility and compression, ensuring a good seal even under varying temperatures and pressure. Rubber gaskets are relatively inexpensive and easy to install. However, they have a limited lifespan compared to other materials, typically degrading over time due to oil exposure and heat.

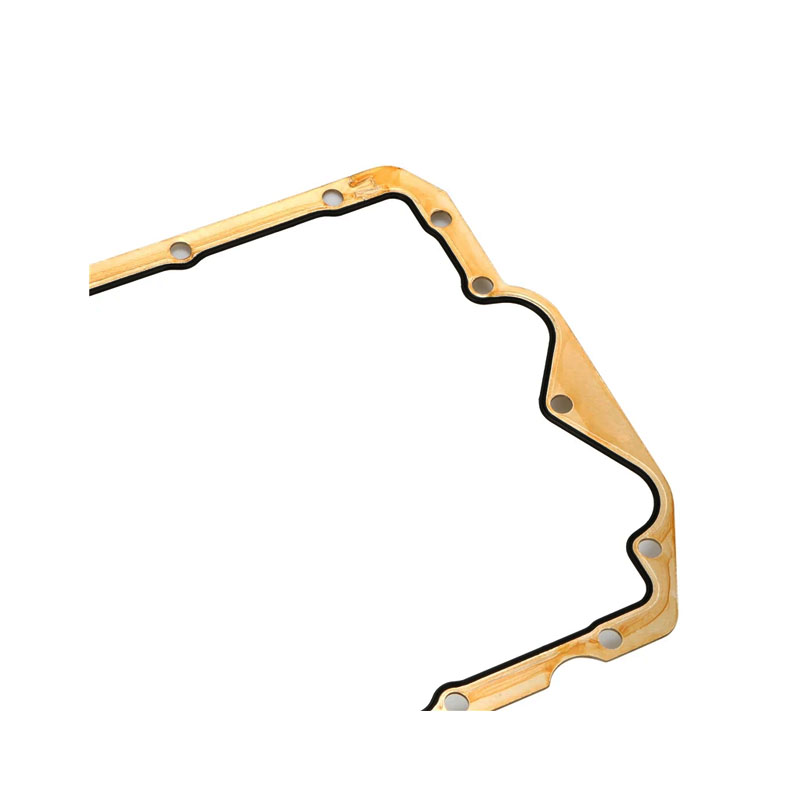

2. Cork Gaskets Cork is another traditional material for oil pan gaskets. It is lightweight and offers good sealing properties due to its natural compressibility. Cork gaskets are often combined with other materials (like rubber) to enhance their durability. While cork is effective, it can dry out and become brittle, leading to leaks over time.

3. Silicone Gaskets Silicone has gained popularity in recent years due to its superior resistance to heat and chemical exposure. Silicone gaskets can withstand higher temperatures than rubber or cork and do not degrade as quickly in the presence of oil. They provide an excellent seal and are flexible, making them ideal for applications where precise fitment is required. However, silicon gaskets can be more expensive and may require a longer curing time during installation.

4. RTV Sealants Room Temperature Vulcanizing (RTV) sealants are not traditional gaskets but are widely used in oil pan sealing. RTV sealants offer exceptional adhesion and sealing properties. They can be molded to fit any shape and are particularly useful when dealing with irregular mating surfaces. However, proper application is crucial, as improper curing can lead to leaks.

best gasket material for oil pan

5. Metal Gaskets For high-performance applications, metal gaskets (like those made from aluminum or steel) are often preferred. They are incredibly durable and can withstand extreme temperatures and pressures. However, metal gaskets usually require precise manufacturing and fitting, making them more suitable for experienced mechanics or specialized applications.

Factors to Consider When Choosing a Gasket Material

When selecting a gasket material for your oil pan, consider the following factors

1. Engine Type and Application The type of engine (e.g., performance vs. standard) and its operational conditions (e.g., temperature range, pressure) will significantly influence the choice of gasket material.

2. Cost and Availability While some high-performance materials may be the best choice, it’s essential to balance performance with budget constraints. Evaluate the availability of specific gasket types in your region as well.

3. Installation and Maintenance Some materials are easier to install than others. If you're a DIYer, consider a gasket material that you can easily work with and that will hold up without excessive maintenance.

4. Durability and Lifespan Look for materials that can withstand the specific operating conditions of your engine without degrading too quickly. Opting for a more durable material may lead to lower maintenance costs over time.

Conclusion

Choosing the best gasket material for your oil pan is vital to maintaining the health of your engine. While rubber and cork gaskets provide cost-effective solutions, silicone and metal options offer enhanced durability for more demanding applications. By taking the factors mentioned into account, you can make an informed decision that will help you avoid leaks and ensure your engine runs smoothly for years to come.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories